Content Menu

● Understanding Aluminum Extrusions

● Properties of Aluminum

● Weight Capacity of 1.5 x 3 Aluminum Extrusion

>> Factors Influencing Weight Capacity

>> Calculating Weight Capacity

● Applications of 1.5 x 3 Aluminum Extrusion

● Advantages of Using Aluminum Extrusions

● Best Practices for Using 1.5 x 3 Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is the maximum load a 1.5 x 3 aluminum extrusion can support?

>> 2. Can I use 1.5 x 3 aluminum extrusion for outdoor applications?

>> 3. How do I cut 1.5 x 3 aluminum extrusion?

>> 4. Is it possible to weld 1.5 x 3 aluminum extrusions?

>> 5. What are the common alloys used for 1.5 x 3 aluminum extrusions?

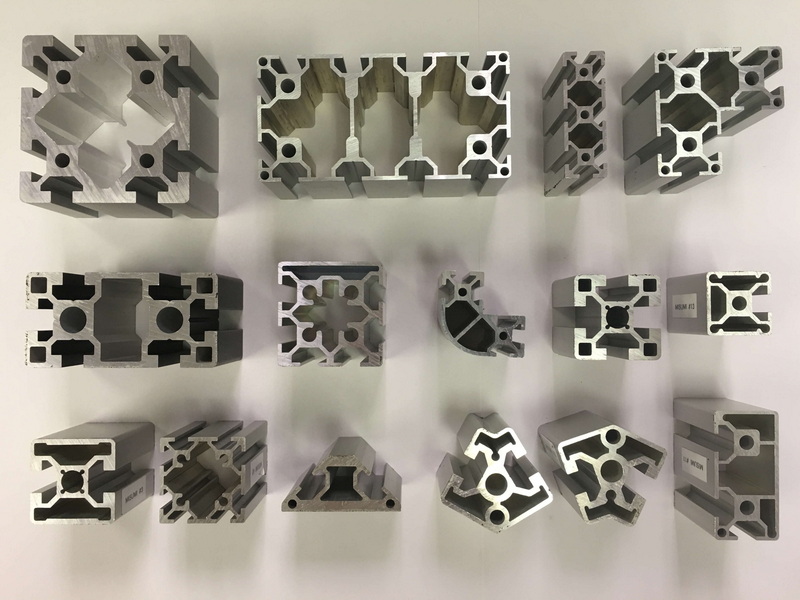

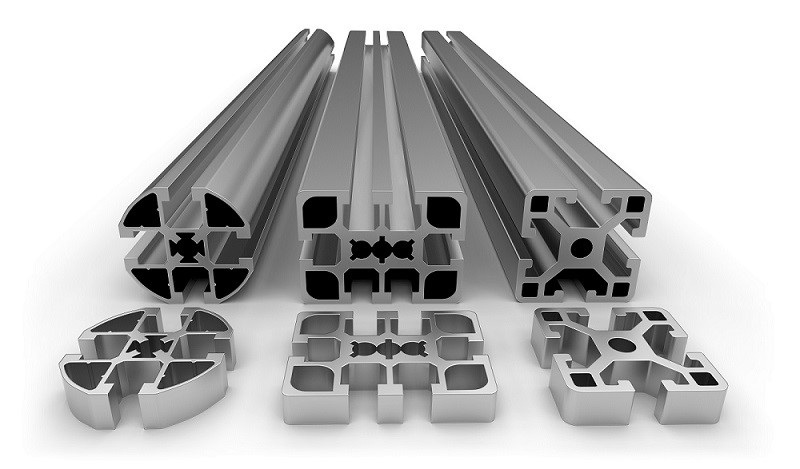

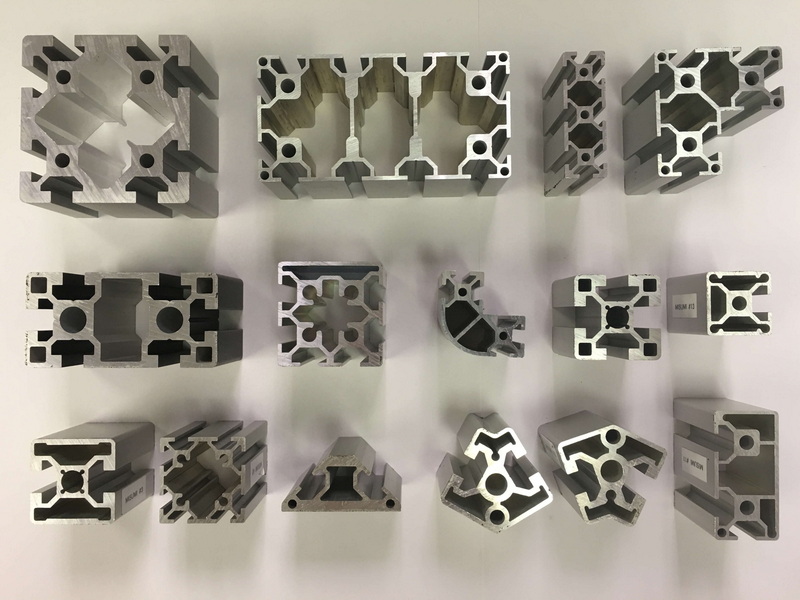

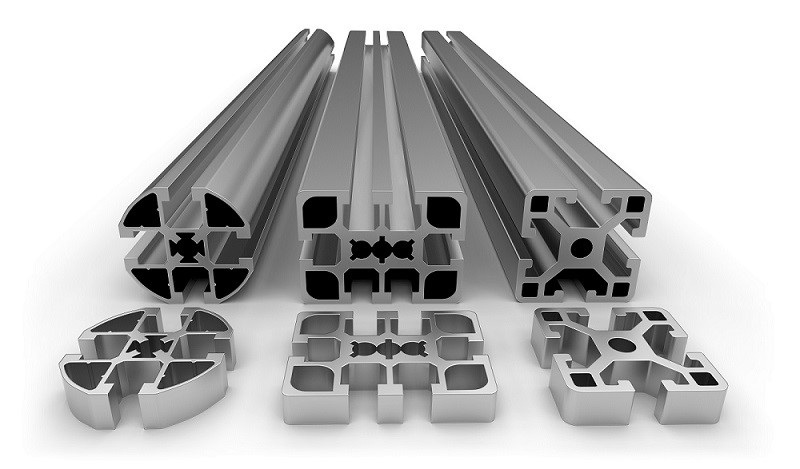

Understanding Aluminum Extrusions

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. Among the many sizes available, the 1.5 x 3 aluminum extrusion is particularly popular for its balance of strength and weight. This article will explore the weight capacity of 1.5 x 3 aluminum extrusions, their applications, and factors that influence their load-bearing capabilities.

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die. This process allows for the creation of complex shapes and profiles that can be used in a variety of applications. The 1.5 x 3 aluminum extrusion refers to a specific profile size, where the dimensions indicate the width and height of the extrusion in inches.

Properties of Aluminum

Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. These properties make it an ideal material for structural applications. The specific alloy used in the extrusion process can also affect its weight capacity. Common alloys for aluminum extrusions include 6061 and 6063, each offering different mechanical properties.

6061 aluminum is a heat-treatable alloy that provides good mechanical properties and is often used in structural applications. It has a higher tensile strength compared to 6063 aluminum, making it suitable for applications that require greater load-bearing capabilities. On the other hand, 6063 aluminum is more malleable and is often used for architectural applications due to its aesthetic finish and ease of fabrication.

Weight Capacity of 1.5 x 3 Aluminum Extrusion

The weight capacity of a 1.5 x 3 aluminum extrusion depends on several factors, including the alloy used, the length of the extrusion, and the type of load applied (static or dynamic). Generally, aluminum extrusions are designed to support significant loads while remaining lightweight.

Factors Influencing Weight Capacity

1. Alloy Type: Different aluminum alloys have varying tensile strengths. For example, 6061 aluminum is stronger than 6063, making it more suitable for heavy-duty applications.

2. Length of the Extrusion: The longer the extrusion, the more it can flex under load. Shorter lengths typically have higher weight capacities due to reduced bending moments.

3. Load Type: Static loads (constant weight) and dynamic loads (changing weight) affect the extrusion differently. Dynamic loads can lead to fatigue over time, reducing the effective weight capacity.

4. Mounting and Support: How the extrusion is mounted and supported also plays a crucial role. Properly supported extrusions can carry more weight than those that are inadequately supported.

Calculating Weight Capacity

To determine the weight capacity of a 1.5 x 3 aluminum extrusion, engineers often use formulas that take into account the material properties, dimensions, and load conditions. While specific calculations can be complex, a general rule of thumb is that a well-supported aluminum extrusion can typically handle a load of around 100 to 200 pounds per linear foot, depending on the factors mentioned above.

Applications of 1.5 x 3 Aluminum Extrusion

The versatility of 1.5 x 3 aluminum extrusions makes them suitable for a wide range of applications, including:

- Structural Frameworks: Used in building frames, scaffolding, and support structures. The lightweight nature of aluminum allows for easier handling and installation, making it a preferred choice in construction.

- Machinery and Equipment: Commonly found in the construction of machinery frames and equipment housings. The strength of aluminum extrusions provides the necessary support for heavy machinery while minimizing overall weight.

- Furniture: Used in the design of modern furniture, providing both aesthetic appeal and structural integrity. Aluminum extrusions can be easily shaped and finished, allowing for innovative furniture designs.

- Transportation: Employed in the manufacturing of lightweight vehicle components, enhancing fuel efficiency. The automotive and aerospace industries benefit from the use of aluminum extrusions to reduce weight without compromising strength.

- Display and Signage: Aluminum extrusions are often used in the creation of display stands and signage due to their durability and ability to be customized for various designs.

Advantages of Using Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport. This characteristic is particularly beneficial in applications where weight reduction is critical.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, preventing rust and corrosion. This property extends the lifespan of products made from aluminum extrusions, especially in outdoor or harsh environments.

3. Customizability: The extrusion process allows for the creation of custom shapes and sizes to meet specific project requirements. This flexibility enables designers and engineers to create unique solutions tailored to their needs.

4. Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice. The recycling process requires only a fraction of the energy needed to produce new aluminum, contributing to sustainability efforts.

5. Thermal Conductivity: Aluminum has excellent thermal conductivity, making it suitable for applications that require heat dissipation, such as heat sinks in electronic devices.

Best Practices for Using 1.5 x 3 Aluminum Extrusion

To maximize the weight capacity and longevity of 1.5 x 3 aluminum extrusions, consider the following best practices:

1. Proper Support: Ensure that the extrusion is adequately supported at both ends and at regular intervals along its length. This support minimizes bending and flexing, which can lead to failure.

2. Avoid Overloading: Be mindful of the weight limits and avoid exceeding the recommended load capacity. Regularly assess the load conditions to ensure safety.

3. Regular Inspections: Periodically inspect the extrusions for signs of wear, fatigue, or corrosion. Early detection of issues can prevent catastrophic failures.

4. Use Appropriate Fasteners: Select fasteners that are compatible with aluminum to prevent galvanic corrosion. Stainless steel fasteners are often recommended for use with aluminum.

5. Consider Environmental Factors: When using aluminum extrusions in outdoor applications, consider factors such as temperature fluctuations, humidity, and exposure to chemicals. Protective coatings can enhance durability.

Conclusion

The weight capacity of 1.5 x 3 aluminum extrusions is influenced by various factors, including the alloy type, length, load type, and support conditions. Understanding these factors is crucial for engineers and designers to ensure safe and effective use of aluminum extrusions in their projects. With their lightweight, strength, and versatility, 1.5 x 3 aluminum extrusions continue to be a popular choice across multiple industries.

Frequently Asked Questions

1. What is the maximum load a 1.5 x 3 aluminum extrusion can support?

- A well-supported 1.5 x 3 aluminum extrusion can typically handle between 100 to 200 pounds per linear foot, depending on various factors.

2. Can I use 1.5 x 3 aluminum extrusion for outdoor applications?

- Yes, aluminum is naturally corrosion-resistant, making it suitable for outdoor use. However, consider using a protective coating for added durability.

3. How do I cut 1.5 x 3 aluminum extrusion?

- Use a miter saw with a fine-toothed blade designed for cutting aluminum. Ensure to secure the extrusion properly before cutting.

4. Is it possible to weld 1.5 x 3 aluminum extrusions?

- Yes, aluminum can be welded, but it requires specific techniques and equipment. It is often recommended to use mechanical fasteners for ease of assembly.

5. What are the common alloys used for 1.5 x 3 aluminum extrusions?

- The most common alloys are 6061 and 6063, with 6061 offering higher strength and 6063 being more versatile for architectural applications.