Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Types of 90-Degree Aluminum Extrusion Components

● Price Range for 90-Degree Aluminum Extrusion Components

>> Typical Pricing Examples

● Factors Affecting Pricing

● Applications of 90-Degree Aluminum Extrusion Components

>> Industrial Applications

● Considerations When Purchasing

● Future Trends in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What materials are commonly used for aluminum extrusion?

>> 2. How can I reduce costs when purchasing aluminum extrusions?

>> 3. Are there any special considerations when using corner brackets?

>> 4. Can I customize my aluminum extrusion components?

>> 5. What is the lead time for ordering aluminum extrusions?

Aluminum extrusion has become a cornerstone in various industries, from construction to manufacturing and DIY projects. Among the many components produced through this process, 90-degree aluminum extrusion components are particularly popular due to their versatility and strength. This article will explore the price range for these components, factors influencing their costs, applications, and more.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy through a die to create a specific cross-sectional profile. This process allows manufacturers to produce complex shapes that are lightweight yet strong. The resulting profiles can be used in various applications, including structural frameworks, enclosures, and furniture.

Benefits of Aluminum Extrusion

The advantages of using aluminum extrusion include:

- Lightweight: Aluminum is significantly lighter than steel or other metals, making it easier to handle and transport.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer that prevents corrosion, enhancing durability.

- Versatility: The extrusion process allows for a wide variety of shapes and sizes, accommodating diverse design requirements.

- Cost-Effectiveness: While the initial cost may be higher than some materials, the longevity and low maintenance of aluminum often lead to lower overall costs.

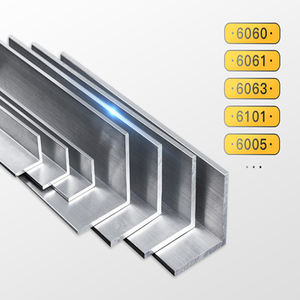

Types of 90-Degree Aluminum Extrusion Components

When discussing 90-degree aluminum extrusion, several types of components come to mind:

- L Brackets: Used for joining two pieces of aluminum at a right angle. They provide strong support and stability in various applications.

- T Plates: These plates connect profiles at a 90-degree angle and are often used in assembly. They can be used in furniture making or as connectors in larger structures.

- Corner Brackets: Designed specifically for reinforcing corners in structures. These brackets ensure that joints remain tight and secure under load.

Each type has its own unique specifications and uses, which can affect pricing.

Price Range for 90-Degree Aluminum Extrusion Components

The price of 90-degree aluminum extrusion components can vary significantly based on several factors:

- Material Quality: The type of aluminum alloy used can influence the price. Common alloys include 6061 and 6063, with 6061 being more expensive due to its superior strength and corrosion resistance.

- Size and Complexity: Larger or more complex designs require more material and sophisticated tooling, driving up costs.

- Quantity Ordered: Bulk orders typically reduce the cost per unit due to economies of scale.

- Finishing Options: Additional processes like anodizing or powder coating enhance durability and aesthetics but add to the overall cost.

Typical Pricing Examples

- L Brackets: Prices can range from $0.91 to $6.69 per piece depending on size and brand.

- T Plates: Generally priced between $2.87 and $5 per piece based on quality and finish.

- Corner Brackets: These can range from $0.60 to $3.50 each, depending on the design complexity.

Overall, the average cost for standard 90-degree aluminum extrusion components is approximately $3 to $8 per pound, with custom profiles costing more due to additional processing requirements.

Factors Affecting Pricing

Several factors contribute to the pricing of aluminum extrusion components:

1. Material Costs: Fluctuations in the global aluminum market can significantly impact prices.

2. Design Complexity: More intricate designs require specialized tooling, increasing costs.

3. Surface Treatments: Processes like anodizing or powder coating enhance appearance and durability but add extra costs.

4. Production Volume: Larger orders generally result in lower prices per unit due to reduced setup time and material waste.

5. Lead Time Requirements: Urgent orders may incur additional charges due to expedited processing.

Applications of 90-Degree Aluminum Extrusion Components

The versatility of 90-degree aluminum extrusion components makes them suitable for various applications:

- Construction Frameworks: Used in building structures such as frames for solar panels or support systems for machinery. Their strength-to-weight ratio makes them ideal for structural applications where weight is a concern.

- Furniture Assembly: Ideal for creating sturdy furniture pieces that require precise angles. Many modern furniture designs utilize aluminum extrusions for their clean lines and contemporary aesthetic.

- DIY Projects: Commonly employed in home improvement projects where strong joints are necessary. Hobbyists appreciate the ease with which they can assemble projects using these components.

Industrial Applications

In industrial settings, 90-degree aluminum extrusion components are often found in:

- Automotive Manufacturing: Used in vehicle frames and supports where lightweight materials contribute to fuel efficiency without sacrificing safety.

- Aerospace Engineering: Critical in aircraft design where weight reduction is paramount while maintaining structural integrity.

- Electronics Enclosures: Providing robust housing solutions that protect sensitive electronic components while allowing for efficient heat dissipation.

Considerations When Purchasing

When looking to purchase 90-degree aluminum extrusion components, consider the following:

- Supplier Reputation: Choose suppliers with good reviews and a history of quality products. Reliable suppliers often provide better customer service and support throughout the purchasing process.

- Customization Options: If your project requires specific dimensions or features, inquire about customization options early on. Many manufacturers offer tailored solutions that meet unique project requirements.

- Shipping Costs: Factor shipping costs into your budget as they can significantly impact overall expenses, especially for bulk orders or large components.

Future Trends in Aluminum Extrusion

The demand for aluminum extrusions is expected to grow due to several trends:

1. Sustainability Initiatives: As industries move towards greener practices, lightweight materials like aluminum will gain popularity due to their recyclability and lower carbon footprint compared to traditional materials like steel.

2. Technological Advancements: Innovations in manufacturing processes will enhance customization capabilities while reducing production times and costs.

3. Growing Industries: Sectors such as renewable energy (solar panels) and electric vehicles are expanding rapidly, increasing the demand for high-quality aluminum extrusions tailored to specific applications.

Conclusion

In summary, the price range for 90-degree aluminum extrusion components varies based on material quality, design complexity, quantity ordered, and finishing options. Generally, prices fall between $3 to $8 per pound for standard profiles, with custom options costing more. The versatility of these components makes them invaluable across multiple industries, from construction to DIY projects. With ongoing advancements in technology and growing demand across various sectors, the future looks bright for aluminum extrusions as they continue to play a crucial role in modern manufacturing processes.

FAQ

1. What materials are commonly used for aluminum extrusion?

Aluminum alloys like 6061 and 6063 are commonly used due to their strength and corrosion resistance.

2. How can I reduce costs when purchasing aluminum extrusions?

Ordering in bulk typically lowers the price per unit due to economies of scale.

3. Are there any special considerations when using corner brackets?

Ensure proper alignment during installation to maintain structural integrity at right angles.

4. Can I customize my aluminum extrusion components?

Yes, many manufacturers offer custom profiles tailored to specific project needs.

5. What is the lead time for ordering aluminum extrusions?

Lead times vary by manufacturer but typically range from a few days to several weeks depending on production volume and complexity.