Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Tools for Cutting Aluminum Extrusion

>> Miter Saw

>> Band Saw

>> Circular Saw

>> Hacksaw

>> Table Saw

● Preparing to Cut Aluminum Extrusion

>> Measure and Mark

>> Secure the Extrusion

>> Choose the Right Blade

● Cutting Techniques

>> Using a Miter Saw

>> Using a Band Saw

>> Using a Circular Saw

>> Using a Hacksaw

>> Using a Table Saw

● Safety Precautions

● Tips for Achieving Precise Cuts

● Common Mistakes to Avoid

● Maintenance of Cutting Tools

● Conclusion

● Frequently Asked Questions

>> 1. What is the best tool for cutting aluminum extrusion?

>> 2. Can I use a regular saw blade to cut aluminum?

>> 3. What safety gear should I wear when cutting aluminum?

>> 4. How do I prevent aluminum from binding during cutting?

>> 5. Is it necessary to use a coolant when cutting aluminum?

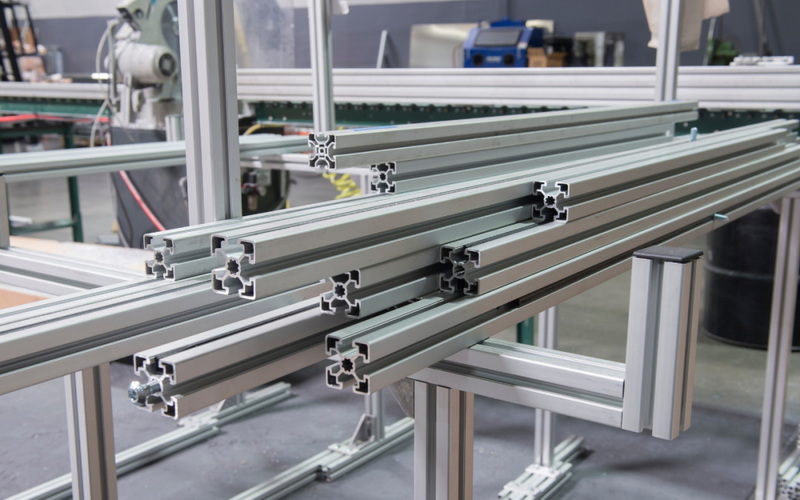

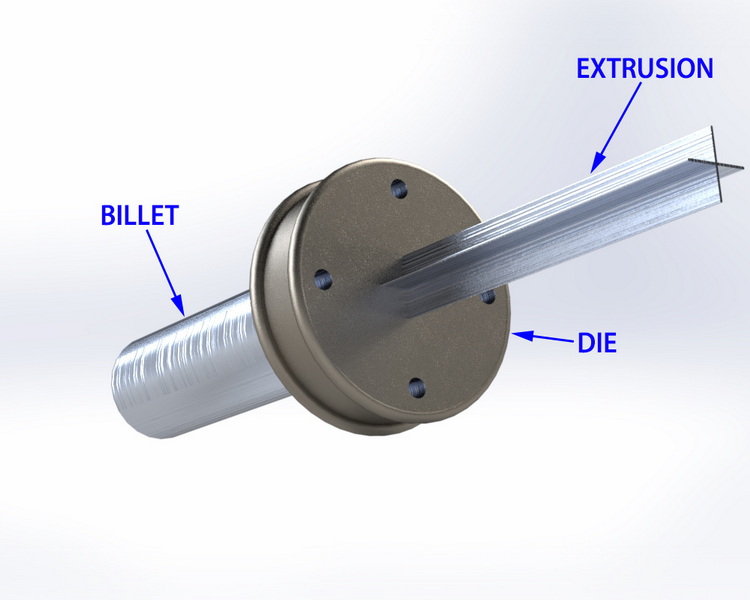

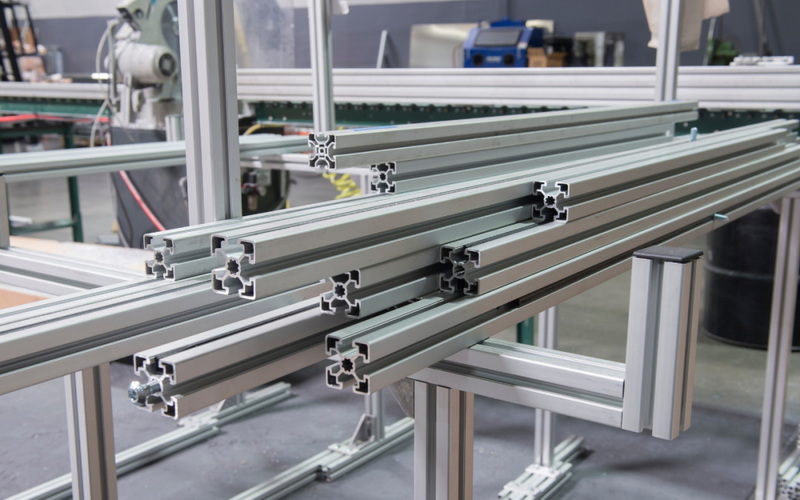

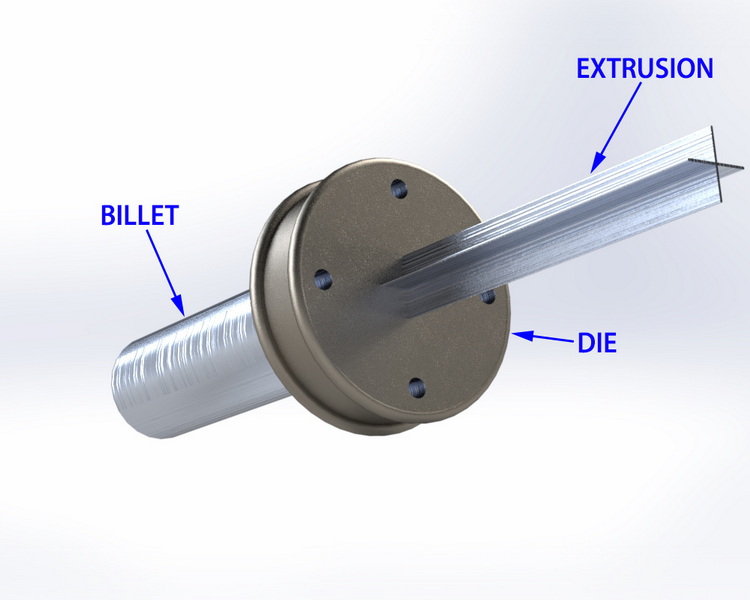

Understanding Aluminum Extrusion

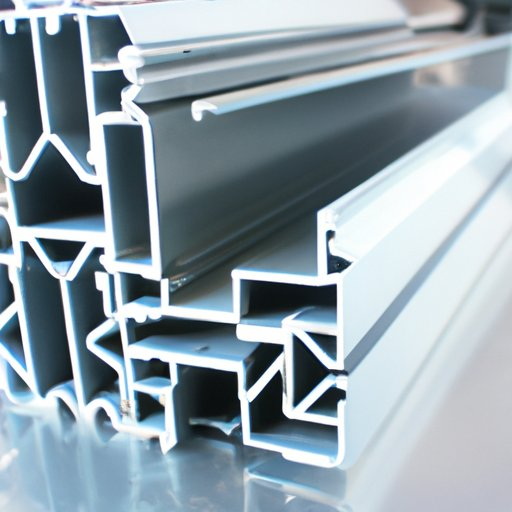

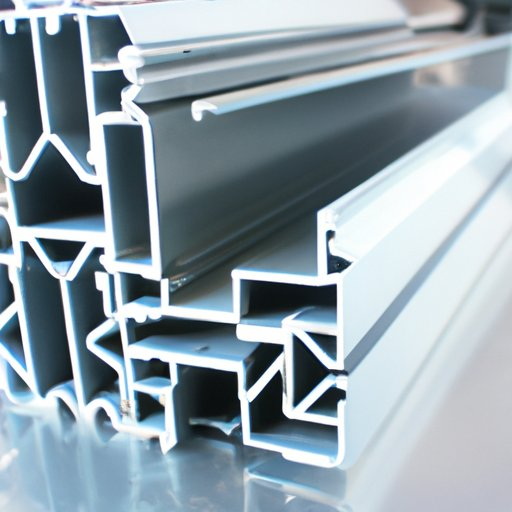

Aluminum extrusion is a process that shapes aluminum alloy into a desired cross-sectional profile. The process involves forcing heated aluminum through a die, creating long lengths of material that can be cut to size. Aluminum extrusions come in various shapes and sizes, making them suitable for applications in construction, automotive, aerospace, and more.

Benefits of Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

3. Versatility: Aluminum extrusions can be easily shaped and customized for different applications.

4. Recyclability: Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice.

Tools for Cutting Aluminum Extrusion

To cut aluminum extrusion effectively, you will need the right tools. Here are some of the most commonly used tools for this purpose:

Miter Saw

A miter saw is one of the best tools for cutting aluminum extrusions. It allows for precise angled cuts and is easy to use. When using a miter saw, ensure you have a blade specifically designed for cutting metal.

Band Saw

A band saw is another excellent option for cutting aluminum. It provides a smooth cut and is ideal for thicker extrusions. When using a band saw, make sure to use a bi-metal blade designed for cutting metal.

Circular Saw

A circular saw can also be used to cut aluminum extrusions, especially for larger pieces. Use a carbide-tipped blade designed for cutting non-ferrous metals to achieve the best results.

Hacksaw

For smaller projects or when precision is not as critical, a hacksaw can be used to cut aluminum extrusion. It is a manual tool that requires more effort but can be effective for quick cuts.

Table Saw

A table saw can be used for cutting aluminum extrusions, especially for long, straight cuts. Ensure you have a suitable blade and take necessary safety precautions.

Preparing to Cut Aluminum Extrusion

Before you start cutting, it's essential to prepare your workspace and the aluminum extrusion itself. Here are some steps to follow:

Measure and Mark

Accurate measurements are crucial for a successful cut. Use a measuring tape to determine the length you need, and mark it clearly with a marker or pencil.

Secure the Extrusion

To ensure a clean cut, secure the aluminum extrusion in place. Use clamps to hold it steady on your workbench or cutting surface. This will prevent movement during the cutting process.

Choose the Right Blade

Selecting the appropriate blade is vital for achieving a clean cut. For most cutting tools, use blades specifically designed for cutting aluminum or non-ferrous metals. These blades have fewer teeth and are designed to reduce friction and heat buildup.

Cutting Techniques

Now that you have your tools and materials ready, let's explore some effective cutting techniques.

Using a Miter Saw

1. Set the Angle: If you need an angled cut, adjust the miter saw to the desired angle.

2. Align the Mark: Position the marked line on the aluminum extrusion with the blade.

3. Cut Slowly: Start the saw and lower the blade slowly onto the extrusion. Allow the saw to do the work without forcing it.

Using a Band Saw

1. Adjust the Speed: Set the band saw to a slower speed for cutting aluminum.

2. Feed Rate: Feed the aluminum extrusion into the blade at a steady rate to avoid binding.

3. Coolant: If cutting thicker pieces, consider using a coolant to reduce heat buildup.

Using a Circular Saw

1. Set the Depth: Adjust the blade depth to slightly more than the thickness of the aluminum extrusion.

2. Cut Straight: Use a straight edge or guide to ensure a straight cut.

3. Steady Pressure: Apply steady pressure while cutting, allowing the blade to do the work.

Using a Hacksaw

1. Manual Control: Use a steady, even motion to cut through the aluminum.

2. Lubrication: Consider using cutting oil to reduce friction and heat.

Using a Table Saw

1. Set the Fence: Adjust the fence to the desired width for a straight cut.

2. Feed Rate: Feed the aluminum extrusion slowly and steadily through the blade.

Safety Precautions

Cutting aluminum can produce sharp edges and metal shavings, so it's essential to take safety precautions:

1. Wear Safety Gear: Always wear safety glasses and gloves to protect yourself from flying debris.

2. Work in a Well-Ventilated Area: Ensure your workspace is well-ventilated to avoid inhaling metal dust.

3. Keep Your Workspace Clean: Regularly clean up metal shavings and debris to prevent accidents.

Tips for Achieving Precise Cuts

1. Double-Check Measurements: Always double-check your measurements before cutting.

2. Use a Stop Block: For repetitive cuts, use a stop block to ensure consistent lengths.

3. Practice on Scrap: If you're new to cutting aluminum, practice on scrap pieces to get a feel for the tool and technique.

Common Mistakes to Avoid

When cutting aluminum extrusion, there are several common mistakes that can lead to poor results. Here are some to watch out for:

1. Not Using the Right Blade: Using a blade not designed for aluminum can lead to rough cuts and damage to the material.

2. Forcing the Cut: Applying too much pressure can cause the blade to bind or break. Let the tool do the work.

3. Ignoring Safety Precautions: Failing to wear safety gear or not securing the material can lead to accidents.

Maintenance of Cutting Tools

To ensure your cutting tools remain effective, regular maintenance is essential. Here are some tips:

1. Keep Blades Sharp: Dull blades can lead to poor cuts and increased heat. Regularly check and replace blades as needed.

2. Clean Tools After Use: Remove any aluminum shavings and debris from your tools to prevent rust and damage.

3. Store Tools Properly: Keep your tools in a dry, safe place to prevent damage and ensure longevity.

Conclusion

Cutting aluminum extrusion can be a simple and effective process when you have the right tools and techniques. Whether you choose a miter saw, band saw, circular saw, or hacksaw, understanding the best practices will help you achieve clean and precise cuts. Always prioritize safety and take the time to prepare your workspace and materials properly.

Frequently Asked Questions

1. What is the best tool for cutting aluminum extrusion?

The best tool depends on the thickness and type of cut needed. A miter saw is often recommended for its precision, while a band saw is great for thicker materials.

2. Can I use a regular saw blade to cut aluminum?

It is best to use a blade specifically designed for cutting aluminum or non-ferrous metals to achieve the best results.

3. What safety gear should I wear when cutting aluminum?

Always wear safety glasses and gloves to protect against flying debris and sharp edges.

4. How do I prevent aluminum from binding during cutting?

Use a slow feed rate and ensure the blade is sharp. Applying cutting oil can also help reduce friction.

5. Is it necessary to use a coolant when cutting aluminum?

While not always necessary, using a coolant can help reduce heat buildup, especially when cutting thicker pieces.

This comprehensive guide provides a detailed overview of cutting aluminum extrusion, including methods, tools, safety tips, and common mistakes to avoid. If you have any further questions or need additional information, feel free to ask!