Content Menu

● Understanding the PP Thick Plate Extrusion Process

● Key Features of a High-Quality PP Thick Plate Extrusion Line

>> 1. Extruder Type and Design

>> 2. Die Head Design

>> 3. Temperature Control System

>> 4. Calendering System

>> 5. Automation Features

● Top Manufacturers of PP Thick Plate Extrusion Lines

>> 1. JWELL Machinery

>> 2. Yesha Engineering

>> 3. Gwell Machinery

● Factors to Consider When Choosing an Extrusion Line

● Applications of PP Thick Plates

● Conclusion

● FAQ

>> 1. What materials can be processed on a PP thick plate extrusion line?

>> 2. How do I choose the right capacity for my production line?

>> 3. What kind of maintenance do these machines require?

>> 4. Can I customize my extrusion line?

>> 5. How long does it take to install an extrusion line?

● Citations:

The demand for polypropylene (PP) thick plates has surged due to their versatility and eco-friendliness. Industries ranging from construction to packaging are increasingly relying on PP thick plates for various applications. To meet this growing demand, investing in a high-quality "PP thick plate extrusion production line"is essential for businesses aiming to enhance their manufacturing capabilities. This article will explore the best options available, key features to consider, and how to select the right production line for your business needs.

Understanding the PP Thick Plate Extrusion Process

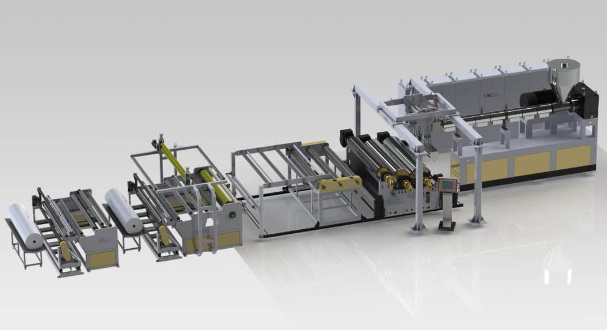

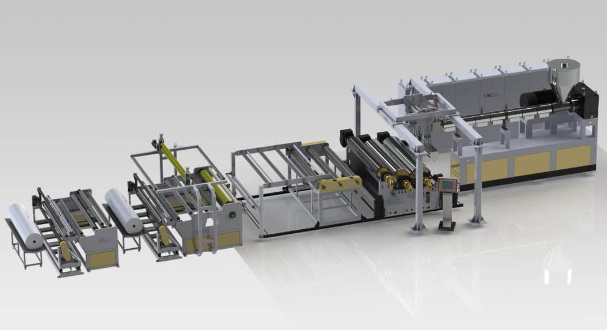

The PP thick plate extrusion process involves several steps:

1. Material Feeding: Raw polypropylene pellets are fed into a single-screw extruder.

2. Melting and Mixing: The extruder melts the pellets and mixes them uniformly.

3. Extrusion: The molten material is forced through a die to form a continuous sheet.

4. Cooling: The extruded sheet is cooled using a three-roll calender or cooling bracket.

5. Trimming and Cutting: Edges are trimmed, and the sheet is cut to the desired length.

6. Winding: The finished sheets are wound onto rolls for storage or further processing.

Key Features of a High-Quality PP Thick Plate Extrusion Line

When selecting a PP thick plate extrusion production line, consider the following key features:

1. Extruder Type and Design

- Single-Screw vs. Twin-Screw Extruders: Single-screw extruders are commonly used for PP thick plate production due to their simplicity and efficiency. However, twin-screw extruders can provide better mixing and processing capabilities, especially for complex formulations.

- Screw Design: A well-designed screw with appropriate compression ratios ensures effective melting and mixing of the polymer.

2. Die Head Design

- Hanger-Type Die Head: This design allows for precise thickness adjustments during production, ensuring uniformity across the sheet.

- Double-Throttle Design: This feature enhances the accuracy of thickness control, which is crucial for meeting product specifications.

3. Temperature Control System

- Precision Control: Advanced temperature control systems can maintain temperatures within ±1°C, ensuring optimal melting and processing conditions.

4. Calendering System

- Three-Roll Calender: This system compresses and smooths the extruded material to achieve the desired thickness and surface finish.

5. Automation Features

- Automatic Trimming and Cutting: Automated systems reduce labor costs and enhance precision in cutting sheets to specified lengths.

- Winding Devices with Torque Motors: These devices help maintain tension and speed during winding, ensuring flatness in the final product.

Top Manufacturers of PP Thick Plate Extrusion Lines

Several manufacturers are renowned for their high-quality PP thick plate extrusion lines:

1. JWELL Machinery

JWELL Machinery offers advanced PP thick plate extrusion lines designed for high efficiency and stability. Their equipment features energy-efficient single-screw extruders, precise temperature control systems, and customizable configurations tailored to specific production needs[1][3].

2. Yesha Engineering

Yesha Engineering specializes in producing reliable sheet extrusion machines, including those specifically designed for PP thick plates. Their machines are known for their robust construction and efficient operation[9].

3. Gwell Machinery

Gwell Machinery provides a range of PP thick plate extrusion lines that emphasize high output and low energy consumption. They also offer extensive after-sales support, ensuring customer satisfaction[7][14].

Factors to Consider When Choosing an Extrusion Line

When selecting a PP thick plate extrusion production line, consider the following factors:

- Production Capacity: Determine your production needs based on market demand. Choose a line that can handle your expected output efficiently.

- Material Compatibility: Ensure that the line can process various grades of polypropylene as well as other materials if needed.

- Customization Options: Look for manufacturers that offer customizable solutions tailored to your specific requirements.

- After-Sales Support: Consider companies that provide comprehensive support services, including installation, training, and maintenance.

Applications of PP Thick Plates

PP thick plates produced from these extrusion lines have diverse applications:

- Construction Industry: Used as formwork, wall panels, and insulation materials.

- Packaging Industry: Ideal for creating durable packaging solutions due to their lightweight yet strong properties.

- Chemical Industry: Employed in manufacturing chemical containers due to their resistance to corrosion and chemicals.

Conclusion

Investing in a high-quality PP thick plate extrusion production line is crucial for businesses looking to capitalize on the growing demand for polypropylene products. By understanding the extrusion process, key features of machinery, and top manufacturers in the industry, you can make an informed decision that aligns with your business goals.

FAQ

1. What materials can be processed on a PP thick plate extrusion line?

PP thick plate extrusion lines primarily process polypropylene but can also handle other materials like PE and ABS depending on the machine specifications.

2. How do I choose the right capacity for my production line?

Assess your market demand and production goals to determine the required capacity. It's advisable to choose a line with some additional capacity to accommodate future growth.

3. What kind of maintenance do these machines require?

Regular maintenance includes checking temperature controls, cleaning dies, lubricating moving parts, and monitoring electrical systems to ensure optimal performance.

4. Can I customize my extrusion line?

Yes, many manufacturers offer customization options based on specific production needs such as width, thickness, and material types.

5. How long does it take to install an extrusion line?

Installation time varies by manufacturer but typically ranges from a few days to several weeks depending on the complexity of the system.

Citations:

[1] https://www.jwellmachine.com/pp-pe-abs-pvc-thick-plate-extrusion-line/

[2] https://www.dynisco.com/userfiles/files/27429_Legacy_Txt.pdf

[3] https://jwell.co/jwell-product/pp-pe-abs-pvc-thick-sheet-extrusion-line/

[4] https://www.youtube.com/watch?v=OcbMvIo7Q14

[5] https://www.albis.com/dam/jcr:9a824d2f-bfef-43fc-aff0-347e3c649310/2018-01%20Guide%20to%20PE_PP%20%20Polyolefin%20Sheet%20Extrusion.pdf

[6] https://www.lookingplas.com/product/showProductDetail?id=15475

[7] https://chinagwell.en.made-in-china.com/product/sSWEXqwbwoUV/China-Gwell-PP-Thick-Plate-Extrusion-Line.html

[8] https://www.jwellextrusions.com/products/plate-extrusion/

[9] https://www.yeshaengineering.com/sheet-extrusion-line.html

[10] https://plastic-extrusionmachines.com/pp-hollow-sheet-extrusion-line/

[11] https://www.facebook.com/sheetextrusionline/

[12] https://www.jwellmachine.com/plate-extrusion-line/

[13] https://www.plasticextrusion-machine.com/sale-15413293-thick-plate-hdpe-extrusion-machine-4-25mm-pp-pe-pellets-material.html

[14] https://gzyokun.en.made-in-china.com/product/JEwYVlkbgpch/China-PP-PE-ABS-Thick-Plate-Production-Line.html

[15] https://jwell.co/jwell-product/pp-pe-abs-pvc-thick-plate-extrusion-line/

[16] https://jwellmachine.en.made-in-china.com/product/iZSGjoKEnTAq/China-Jwell-PP-Thick-Plate-Extruder-Plastic-Production-Sheet-Extrusion-Machine.html

[17] https://www.sheetcoextrusion.com/pp-coroplast-sheet-extrusion-line/

[18] https://www.tradeindia.com/manufacturers/pp-sheet-extrusion-line.html

[19] https://www.plasticextrusion-machine.com/sale-11152204-hdpe-pp-thick-sheet-extrusion-machine-thick-board-production-line-thickness-range-2-15mm.html

[20] https://www.jwell-group.com/Sheetplate-extrusion-machine/tpu-film-extrusion-line

[21] https://www.sheetcoextrusion.com/plastic-sheet-extrusion-line/

[22] https://www.sheet-extrusionline.com/sale-11723916-pp-pe-pvc-thick-plate-big-thickness-board-extrusion-line-extruder-production-line.html

[23] https://www.alibaba.com/product-detail/Jwell-PP-HDPE-PE-ABS-PVC-1600537174136.html

[24] https://www.jwellmachinerys.com/best-quality-pp-extrusion-line-pppeabspvc-thick-plate-extrusion-line-jwell-2-product/

[25] https://www.lookingplas.com/product/showProductDetail?id=15475

[26] https://www.youtube.com/watch?v=x4oe5j0t2-8

[27] https://www.youtube.com/watch?v=tCHje8dmotE

[28] https://weiermachine.en.made-in-china.com/product/HKLxVowCrcrh/China-PP-PE-Thick-Plate-Machinery.html

[29] https://www.youtube.com/watch?v=Yh0gBsDGOzQ

[30] https://www.youtube.com/watch?v=Z1COQNbOjSo

[31] https://www.pinterest.com/pin/sheet-plate-jwell-pipe-extrusion-machine-compounding-jwellpp-pe-abs-pvc-pvdf-thick-plate-plastic-engine-buy-plastic-sheet-extrusion-machineplastic-board-mak--967640669926487094/

[32] https://www.youtube.com/watch?v=-VR3M0AN4DA

[33] https://www.instagram.com/jwellmachinerycpp/reel/C3-C4yFshQm/

[34] https://www.youtube.com/watch?v=3ye9q9Kk-gU

[35] https://www.youtube.com/watch?v=5BLhX7n06pw

[36] https://www.jwellplate.com/solution/pp-pe-pvc-pvdf-thick-board-extrusion-line/

[37] https://www.jwellextrusions.com/products/pe-sheet-extrusion-line/

[38] https://www.jwellextrusion.com/Plastic-plate--sheet-extrusion-line/pp-pe-abs-pvc-thick-plate-extrusion-line

[39] https://www.cowellextrusion.com/everything-you-need-to-know-about-sheet-extrusion-a-comprehensive-guide/

[40] https://jwellmachinery.en.made-in-china.com/product/dNCEZsyJNokO/China-Jwell-PE-PP-2000mm-Thick-Plate-Extrusion-Line-Production-Line-Extrusion-Extruder-Line-Made-in-China.html

[41] https://jwellextruder2.en.made-in-china.com/product/aGvrbQJlqpWN/China-Jwell-PVC-Thick-Plate-Extrusion-Production-Line-PP-PE-ABS-PVC-UHMWPE-Ultra-High-Molecular-Weight-Thick-Plate-Sheet-Board-Plastic-Extrusion-Production-Line.html

[42] https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/extrusion-issue/

[43] https://jwellmachine.en.made-in-china.com/product/iZAfTBtHspaS/China-Jwell-Plastic-PP-PE-ABS-PVC-Thick-Plate-Extrusion-Line.html

[44] https://www.lookingplas.com/product/showProductDetail?id=15472

[45] https://www.jwellmachine.com/pp-pe-pom-board-extrusion-line/

[46] https://www.jwellmachine.com/pp-pe-abs-pvc-thick-plate-extrusion-line/

[47] https://www.youtube.com/watch?v=YSIvHdlircQ