Content Menu

● Understanding Pipe Making Machine Extrusion Lines

>> Key Components of an Extrusion Line

● Factors to Consider When Choosing an Extrusion Line

>> 1. Material Compatibility

>> 2. Pipe Diameter and Thickness

>> 3. Production Capacity

>> 4. Energy Efficiency

>> 5. Automation Level

>> 6. Maintenance and Support

● Best Pipe Making Machine Extrusion Lines on the Market

>> 1. JWELL HDPE Pipe Extrusion Line

>> 2. AMUT HDPE Pipe Production Line

>> 3. WANROOE PVC Pipe Extrusion Line

● The Extrusion Process Explained

● Conclusion

● FAQ

>> 1. What types of pipes can be produced using an extrusion line?

>> 2. How do I determine the right size of an extrusion line?

>> 3. What maintenance is required for an extrusion line?

>> 4. Can I customize my extrusion line?

>> 5. How does automation improve production efficiency?

● Citations:

The pipe making machine extrusion line is a crucial investment for businesses involved in the production of pipes for various applications, including water supply, gas distribution, and industrial uses. Choosing the right extrusion line can significantly impact your production efficiency, product quality, and overall profitability. This article explores the best options available on the market, focusing on key factors to consider when selecting a pipe making machine extrusion line for your business.

Understanding Pipe Making Machine Extrusion Lines

Pipe making machine extrusion lines are designed to produce pipes from various materials, including HDPE (High-Density Polyethylene), PVC (Polyvinyl Chloride), and PP (Polypropylene). The process involves melting plastic pellets and forcing them through a die to form a continuous pipe. Once extruded, the pipes are cooled, cut to length, and packaged for distribution.

Key Components of an Extrusion Line

- Extruder: The heart of the extrusion line, responsible for melting and shaping the material.

- Die: Shapes the molten plastic into the desired pipe profile.

- Cooling System: Cools the extruded pipe to solidify it quickly.

- Haul-off Unit: Pulls the pipe through the cooling system at a controlled speed.

- Cutter: Cuts the pipe into specified lengths.

- Control System: Manages the entire process, ensuring consistent quality and efficiency.

Factors to Consider When Choosing an Extrusion Line

When selecting a pipe making machine extrusion line, consider the following factors:

1. Material Compatibility

Different extrusion lines are designed for specific materials. Ensure that the line you choose can handle the type of plastic you intend to use, such as HDPE, PVC, or PP.

2. Pipe Diameter and Thickness

Determine the range of pipe diameters and wall thicknesses your business requires. Some machines are designed for small diameter pipes, while others can handle larger sizes.

3. Production Capacity

Evaluate your production needs to choose a line that can meet your output requirements. Consider both peak production rates and average daily output.

4. Energy Efficiency

Look for machines that offer energy-saving features. Efficient machines reduce operational costs and contribute to sustainability goals.

5. Automation Level

Modern extrusion lines often come with advanced automation features that enhance precision and reduce labor costs. Look for options with PLC control systems and user-friendly interfaces.

6. Maintenance and Support

Choose manufacturers that offer reliable after-sales support, including maintenance services and access to spare parts.

Best Pipe Making Machine Extrusion Lines on the Market

Here are some of the top pipe making machine extrusion lines available today:

1. JWELL HDPE Pipe Extrusion Line

JWELL's HDPE pipe extrusion line is known for its versatility and high efficiency. It can produce pipes of various sizes and thicknesses while offering energy savings of up to 35%. This line features a Siemens control system for enhanced automation.

2. AMUT HDPE Pipe Production Line

AMUT offers an advanced HDPE pipe production line capable of producing pipes with diameters ranging from 110mm to 500mm at high speeds. It is equipped with state-of-the-art cooling systems and precise control mechanisms.

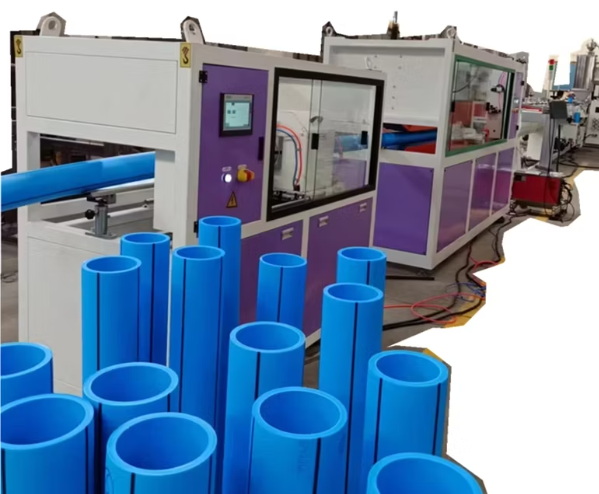

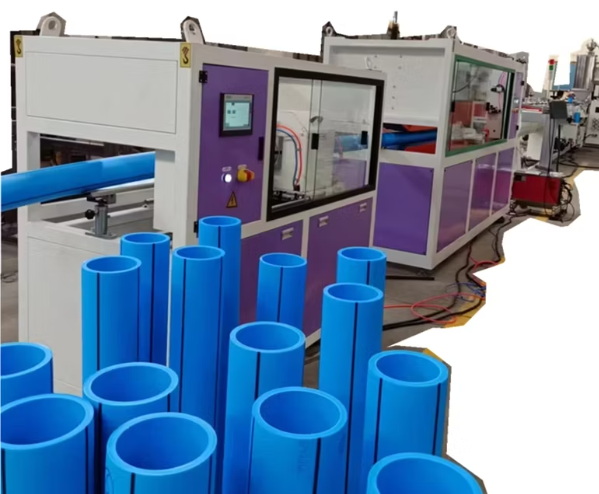

3. WANROOE PVC Pipe Extrusion Line

WANROOE specializes in PVC pipe extrusion lines that cater to various applications such as drainage and water supply systems. Their machines are designed for high output while maintaining low energy consumption.

The Extrusion Process Explained

The extrusion process consists of several stages:

1. Material Feeding: Plastic pellets are fed into the extruder.

2. Melting: The material is heated until it melts into a viscous state.

3. Shaping: The molten plastic is forced through a die to create a continuous pipe shape.

4. Cooling: The extruded pipe is cooled using water or air to solidify it.

5. Cutting: The cooled pipe is cut into specified lengths using automated cutters.

6. Packaging: Finished pipes are packaged for shipment.

Conclusion

Selecting the best pipe making machine extrusion line for your business requires careful consideration of several factors including material compatibility, production capacity, energy efficiency, and automation level. By investing in a high-quality extrusion line tailored to your specific needs, you can enhance productivity, improve product quality, and ultimately increase profitability.

FAQ

1. What types of pipes can be produced using an extrusion line?

You can produce various types of pipes including HDPE, PVC, PP, PPR, and more depending on the capabilities of your chosen machine.

2. How do I determine the right size of an extrusion line?

Consider your production requirements such as desired output capacity, range of pipe diameters needed, and wall thickness specifications.

3. What maintenance is required for an extrusion line?

Regular maintenance includes cleaning components, checking for wear on parts like screws and dies, lubricating moving parts, and ensuring proper calibration.

4. Can I customize my extrusion line?

Yes! Many manufacturers offer customization options based on your specific production needs including size adjustments and additional features.

5. How does automation improve production efficiency?

Automation reduces human error, enhances precision in production processes, allows real-time monitoring, and improves overall operational efficiency.

Citations:

[1] https://www.jwellextrusions.com/products/hdpe-pipe-extrusion-machine/

[2] https://www.swarajextrusion.co.in/testimonial.html

[3] https://www.kaidemac.com/High-Speed-PA-Nylon-Pipe-Production-Line-PA-Nylon-Pipe-Making-Machine-pd47116595.html

[4] https://www.won-plus.com/110-315mm-hdpe-pipe-extrusion-line_p76.html

[5] https://www.youtube.com/watch?v=Kv9wpOf5iVg

[6] https://www.recycle-plant.com/plastic-pipe-making-machine.html

[7] https://www.facebook.com/p/Pvc-pipe-extrusion-production-machine-line-100063766487145/

[8] https://www.jwellextrusions.com/products/pipe-extrusion-machine/

[9] https://www.youtube.com/watch?v=WCznCpciRKw

[10] https://www.friendplasticmachine.com/sale-10884614-50-110-hdpe-pipe-extrusion-line-hdpe-pipe-making-machine-high-productivity.html

[11] https://www.wanrooe.com/hdpe-pipe-extrusion-line/

[12] https://trustymachine.en.made-in-china.com/product-group/selJPCyrHpUt/PVC-Pipe-Extrusion-line-1.html

[13] https://www.youtube.com/watch?v=i7bZx0M4XjY

[14] https://www.twinscrew.net/en/article/How-to-Choose-the-Best-PVC-Pipe-Extrusion-Line.html

[15] https://www.gracepm.com/water-pipe-making-machine/

[16] https://www.xinrongplas.com/news/features-of-hdpe-pipe-extrusion-line.html

[17] https://www.alibaba.com/showroom/large-diameter-pipe-extrusion-machine.html

[18] https://www.youtube.com/watch?v=zcBv_JvFDBI

[19] https://www.youtube.com/watch?v=hladL5UogXw

[20] https://www.alibaba.com/product-detail/Four-Output-PVC-Pipe-Making-Machine_1601026411527.html

[21] https://www.benkextruder.com/plastic-pipe-extrusion-line-solution/

[22] https://www.techgprojects.com/pipe-making-machine.html

[23] https://www.youtube.com/watch?v=lhqV0H4HV-g

[24] https://www.sharcpm.com/product/hdpe-pipe-extrusion-line/

[25] https://www.panchveerengineering.com/testimonial.html

[26] http://etwinternational.com/3-4-corrugated-pipe-extrusion-line-112883.html

[27] https://www.friendplasticmachine.com/supplier-219943-pe-pipe-extrusion-line

[28] https://www.youtube.com/watch?v=EI74LID6TG0

[29] https://www.bogdaplast.com/plastic-pipe-production-line/High%20speed%20PVC%20pipe%20making%20machine%20dual%20PVC%20pipe%20extrusion%20line.html

[30] https://sjdslpm.en.made-in-china.com/product/gdAGckBVCLWi/China-Production-Line-Polypropylene-PPR-Pipe-Extrusion-Extruder-Machine-Manufacturing-Process.html

[31] https://www.youtube.com/watch?v=ROvukxEnfqk

[32] https://www.polytimetech.com/pvco-pipe-extrusion-machine/

[33] https://www.youtube.com/playlist?list=PLpIngtK0c7l-AAp3JyoFuheQCPJ15YIXj

[34] https://www.benkextruder.com/corrugated-pipe-production-line/

[35] https://qdhanhai.en.made-in-china.com/product/WSJxUtLMIjYE/China-CPVC-Pipe-Extrusion-Line-Making-Machine.html