Content Menu

● Introduction to MK9 Bowden Extruders

>> Benefits of Bowden Extruders

● Aluminum Extrusions in 3D Printing

>> Benefits of Aluminum Extrusions

>> Using Aluminum Extrusions with MK9 Bowden Extruders

● Choosing the Best MK9 Bowden Extruder Aluminum Extrusion

>> Example Setup: Aluminum MK8 Bowden Extruder

● Customizing Your Setup

● Conclusion

● FAQ

>> 1. What are the main benefits of using a Bowden extruder?

>> 2. Why are aluminum extrusions preferred in 3D printing?

>> 3. Can I use flexible filaments with a Bowden extruder?

>> 4. How do I choose the best aluminum extrusion for my printer?

>> 5. What are some common issues with Bowden extruders?

● Citations:

In the realm of 3D printing, the choice of extruder and its components can significantly impact the quality and efficiency of prints. Among these components, the MK9 Bowden extruder and aluminum extrusions play crucial roles. This article will delve into the world of MK9 Bowden extruder aluminum extrusions, exploring their benefits, applications, and how they enhance 3D printing experiences.

Introduction to MK9 Bowden Extruders

The MK9 extruder is often associated with upgrades to the MK8 hotend setup, primarily focusing on the feeder mechanism rather than the hotend itself. However, when discussing Bowden extruders, we're referring to a system where the extruder is located away from the hotend, connected by a tube (usually PTFE) that guides the filament. This setup is beneficial for reducing the weight on the print head, allowing for faster movement and potentially better print quality.

Benefits of Bowden Extruders

1. Lighter Print Head: By moving the extruder away from the hotend, the print head becomes lighter, which can improve print speed and reduce vibrations.

2. Easier Maintenance: Bowden systems can be easier to maintain since the extruder is separate from the hotend, making it simpler to access and clean.

3. Cost-Effective: While not always cheaper upfront, using existing components can make Bowden setups cost-effective in the long run.

Aluminum Extrusions in 3D Printing

Aluminum extrusions are widely used in 3D printing for their strength, durability, and versatility. They provide a lightweight yet robust framework for printers, allowing for easy assembly and customization.

Benefits of Aluminum Extrusions

1. Strength-to-Weight Ratio: Aluminum extrusions offer an excellent balance between strength and weight, making them ideal for building frames that need to support heavy components without adding unnecessary mass.

2. Corrosion Resistance: Aluminum naturally resists corrosion, which is beneficial in environments where moisture might be present.

3. Heat Dissipation: Aluminum is a good conductor of heat, which can be advantageous in managing the thermal performance of printers.

Using Aluminum Extrusions with MK9 Bowden Extruders

When combining MK9 Bowden extruders with aluminum extrusions, you create a robust and efficient 3D printing setup. The aluminum frame provides stability and support for the printer, while the Bowden extruder system enhances print speed and reduces weight on the print head.

Choosing the Best MK9 Bowden Extruder Aluminum Extrusion

Choosing the best setup involves considering several factors:

1. Compatibility: Ensure that the extruder and aluminum extrusions are compatible with your printer model.

2. Material Support: Consider the types of filaments you plan to use. Bowden systems can be less ideal for flexible filaments.

3. Budget: Assess the cost of the components and whether they fit within your budget.

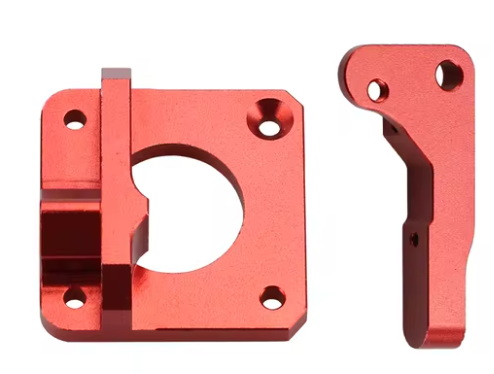

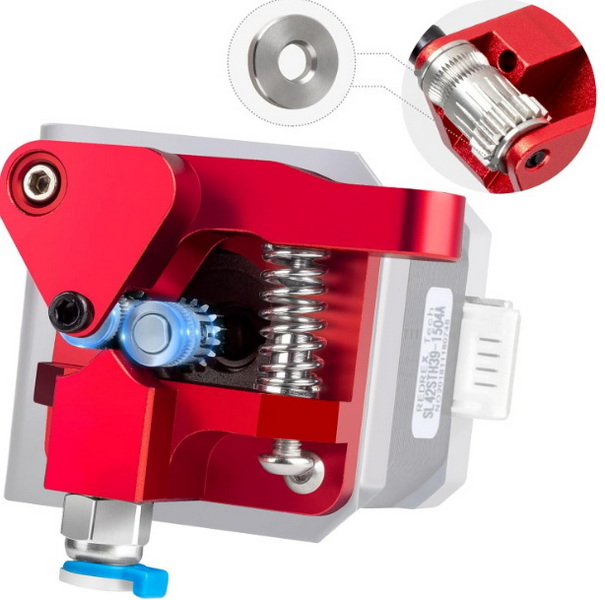

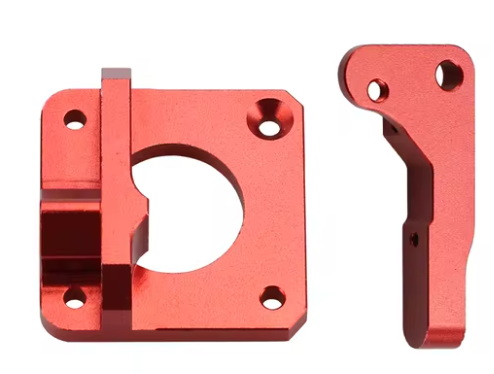

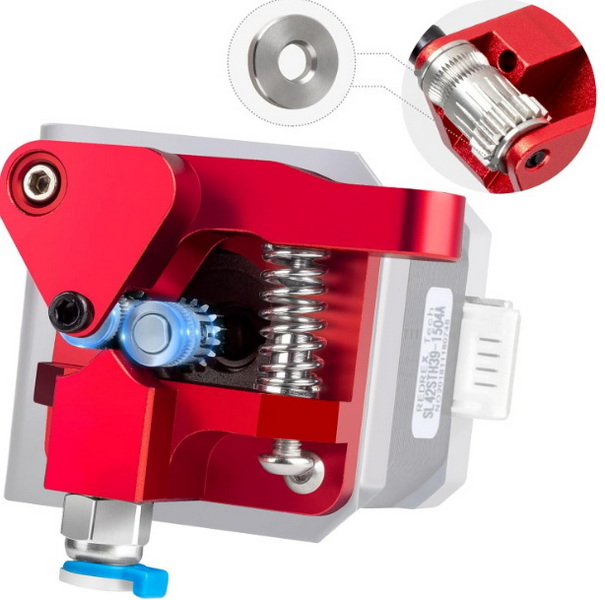

Example Setup: Aluminum MK8 Bowden Extruder

The Aluminum MK8 Bowden Extruder is a popular choice for upgrading from plastic extruders. It is compatible with many Creality and Ender printers and supports 1.75mm filament. This extruder is a good starting point for those looking to enhance their printer's performance without breaking the bank.

Customizing Your Setup

Customization is key to optimizing your 3D printing experience. Here are some tips for customizing your MK9 Bowden extruder aluminum extrusion setup:

1. Use T-Slots for Easy Assembly: Aluminum extrusions often feature T-slots, which make it easy to attach components using T-nuts and bolts.

2. Add Cooling Systems: Consider adding fans or heat sinks to improve thermal management.

3. Experiment with Different Filaments: While Bowden systems are less ideal for flexible filaments, experimenting with different materials can help you find the best balance for your prints.

Conclusion

In conclusion, combining MK9 Bowden extruders with aluminum extrusions offers a robust and efficient 3D printing setup. By understanding the benefits and limitations of these components, you can create a customized printer that meets your specific needs. Whether you're upgrading for better performance or simply looking to enhance your printing experience, this combination is definitely worth considering.

FAQ

1. What are the main benefits of using a Bowden extruder?

- The main benefits include a lighter print head, easier maintenance, and potentially faster print speeds due to reduced weight.

2. Why are aluminum extrusions preferred in 3D printing?

- Aluminum extrusions are preferred for their strength, lightweight nature, corrosion resistance, and good heat dissipation properties.

3. Can I use flexible filaments with a Bowden extruder?

- While possible, printing flexible filaments with a Bowden setup can be challenging and may require additional components like a Capricorn tube for better performance.

4. How do I choose the best aluminum extrusion for my printer?

- Consider compatibility with your printer model, the types of filaments you plan to use, and your budget when selecting aluminum extrusions.

5. What are some common issues with Bowden extruders?

- Common issues include filament jams, PTFE tube misalignment, and the need for precise calibration to ensure smooth operation.

Citations:

[1] https://www.cnckitchen.com/blog/which-is-the-strongest-3d-printing-extruder

[2] https://toms3d.org/2015/07/31/review-the-bondtech-extruder/

[3] https://www.youtube.com/watch?v=CwGimohCH8A

[4] https://www.youtube.com/watch?v=yLH4K1vNoXo

[5] https://www.youtube.com/watch?v=UtemZqFJ5rY

[6] https://3dprinting.stackexchange.com/questions/9915/what-makes-an-extruder-right-handed

[7] https://www.tinytronics.nl/en/3d-printing/extrusion/hotends-and-extruders/aluminum-mk8-bowden-extruder-right

[8] https://aec.org/features-benefits

[9] https://3dprinting.stackexchange.com/questions/5434/which-is-the-difference-between-mk6-and-mk8-and-even-mk10

[10] https://www.youtube.com/watch?v=-S8Pf58zP4k

[11] https://www.reddit.com/r/ender5plus/comments/11eulbg/how_necessary_is_to_change_the_bowden_extruder_to/

[12] https://www.aliexpress.com/i/32948466677.html

[13] https://www.aliexpress.com/item/32889124750.html

[14] https://www.reddit.com/r/ender3v2/comments/149wfud/metal_extruder_upgrade/

[15] https://www.alibaba.com/product-detail/MK9--MK8--Extruder--Aluminum--Alloy--Block-62406127694.html

[16] https://he.aliexpress.com/item/32948466677.html

[17] https://www.aliexpress.com/item/1005003280660537.html

[18] https://www.youtube.com/watch?v=yqKK5SI2Gzg

[19] https://www.yeggi.com/q/bowden+extruder/

[20] https://www.newegg.com/p/2S7-07JP-1A0X2

[21] https://www.reddit.com/r/ender3/comments/eqeddp/the_all_aluminum_extruder_upgrade_is_only_ten/

[22] https://www.reddit.com/r/3Dprinting/comments/18xjk3g/why_so_many_bowden_printers/

[23] https://www.aliexpress.com/item/32398949997.html

[24] https://www.thingiverse.com/thing:2497322

[25] https://m.alibaba.com/showroom/mk9-extruder.html

[26] https://www.yeggi.com/q/bowden+extruder/10/

[27] https://www.yeggi.com/q/bowden+extruder+mount/

[28] https://www.youtube.com/watch?v=-IXmkm5VEu4

[29] https://grabcad.com/library?page=2&softwares=solidworks&sort=most_downloaded&tags=extruder

[30] https://www.youtube.com/watch?v=RxCCPewGrKk

[31] https://www.aliexpress.com/w/wholesale-left-handed-extruder.html

[32] https://gbr.grandado.com/products/mk8-mk9-red-extruder-for-3d-printer-aluminum-block-all-metal-bowden-exruder-kit-right-left-hand-1-75mm-filament-cr-7-cr-10?variant=UHJvZHVjdFZhcmlhbnQ6NzEwMzQwMTI5

[33] https://forum.v1e.com/t/mk9-extruder/3588

[34] https://www.reddit.com/r/ender5plus/comments/n02dbn/reason_to_upgrade_to_an_all_metal_mk8_extruder/

[35] https://www.youtube.com/watch?v=AAe7k_X7kQg

[36] https://reprap.org/forum/read.php?397%2C639675