Content Menu

● Introduction to Foam Sheet Extrusion

>> Types of Foam Sheet Extrusion Equipment

● Factors Influencing the Best Foam Sheet Extrusion Equipment Price

● Innovations in Foam Sheet Extrusion Technology

● Best Practices for Choosing Foam Sheet Extrusion Equipment

● Optimizing Efficiency in Foam Sheet Extrusion

● Environmental Considerations

● Future Trends in Foam Sheet Extrusion

● Conclusion

● FAQ

>> 1. What is the typical price range for EPE foam sheet extrusion equipment?

>> 2. How does the cost of EPS foam sheet extrusion equipment compare to EPE?

>> 3. What factors influence the cost of TPU foam sheet extrusion equipment?

>> 4. How important is automation in foam sheet extrusion equipment?

>> 5. What are the key considerations when choosing between different types of foam sheet extrusion equipment?

● Citations:

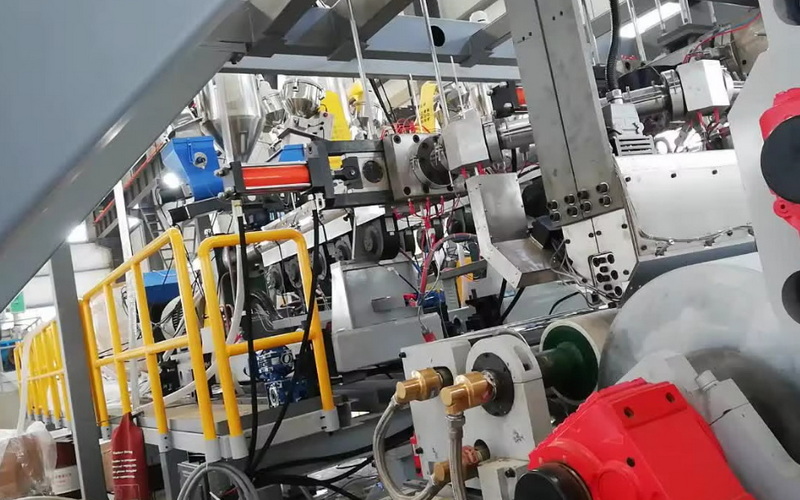

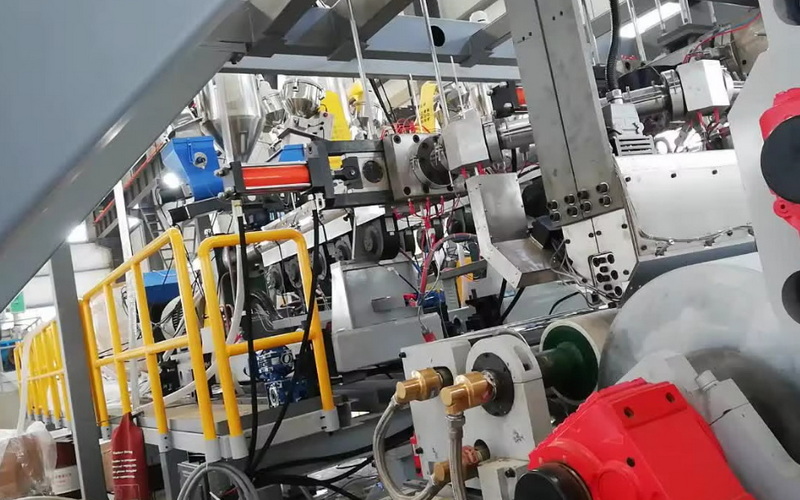

Foam sheet extrusion is a critical process in the manufacturing of various foam products, including packaging materials, insulation, and cushioning. The cost of foam sheet extrusion equipment can vary widely based on factors such as the type of foam, production capacity, and technological sophistication. In this article, we will explore the different types of foam sheet extrusion equipment, their prices, and what makes them the best options for various applications.

Introduction to Foam Sheet Extrusion

Foam sheet extrusion involves the use of polymers like polyethylene (PE), polypropylene (PP), and polystyrene (PS) to create foam sheets. The process typically involves mixing the polymer with a foaming agent, heating it to melt, and then extruding it through a die to form the desired shape. The choice of equipment depends on the specific requirements of the product, such as thickness, density, and material properties.

Types of Foam Sheet Extrusion Equipment

1. EPE Foam Sheet Extrusion Equipment: EPE (Expanded Polyethylene) foam is widely used for packaging due to its shock-absorbing properties and moisture resistance. EPE foam sheet extruders typically range in price from $45,000 to $150,000, depending on the output capacity and features like automation and customization options.

2. EPS Foam Sheet Extrusion Equipment: EPS (Expanded Polystyrene) foam is commonly used for insulation and packaging. The price for EPS foam sheet extrusion machines can be higher, often around ₹1,95,00,000 (approximately $250,000 USD) for a 250 kg/hr capacity machine.

3. XPS Foam Sheet Extrusion Equipment: XPS (Extruded Polystyrene) foam is known for its high thermal insulation properties and is used in building materials. The cost of XPS foam extrusion lines can be substantial due to the complexity of the process and the high-quality requirements of the product.

4. TPU Foam Sheet Extrusion Equipment: TPU (Thermoplastic Polyurethane) foam is used in applications requiring flexibility and durability, such as shoe midsoles. TPU foam sheet extruders are priced based on their capacity and features, with prices starting from around $50,000 for basic models.

5. PP Foam Sheet Extrusion Equipment: Recently, Sulzer Chemtech and Borealis have developed new PP foam extrusion technology that reduces costs and increases efficiency. This innovation uses extrusion with direct gas impregnation, offering a cost-effective alternative to traditional methods and supporting more circular solutions in the plastics industry[1].

Factors Influencing the Best Foam Sheet Extrusion Equipment Price

When determining the best foam sheet extrusion equipment price, several factors must be considered:

- Production Capacity: Higher output capacities generally increase the cost of the equipment. For example, ALEMO's foam sheet extrusion lines range from 150 kg/h to 1000 kg/h, with prices varying accordingly[6].

- Material Type: Different materials require specific processing conditions, affecting the cost. EPE and EPS foams are generally less expensive to process than XPS or TPU.

- Automation Level: Fully automated systems are more expensive but offer higher efficiency and consistency in production.

- Customization Options: Machines with customization options for thickness, density, and color can be more costly.

Innovations in Foam Sheet Extrusion Technology

Recent innovations in foam sheet extrusion technology have focused on improving efficiency, reducing costs, and enhancing product quality:

- EPE Foam Sheet Extrusion Innovations: Modern EPE foam extrusion machines are designed for high efficiency and precision, with advanced computer systems for setting production parameters. These machines can produce foam sheets with various thicknesses and densities, meeting diverse industry needs[5].

- PVC Foam Board Extrusion Innovations: The PVC foam board extrusion process is evolving with the integration of digital technologies like IoT and AI, which optimize production parameters and enhance quality control. Additionally, there is a focus on sustainable practices and customization options[3].

- PS Foam Sheet Extrusion Case Studies: Studies have shown that optimizing extruder design and screw technology can significantly improve foam quality and production efficiency. For instance, using advanced mixing screws can reduce thermal gradients and improve uniformity in PS foam sheets[2].

Best Practices for Choosing Foam Sheet Extrusion Equipment

To select the best foam sheet extrusion equipment at an optimal price, consider the following:

1. Assess Production Needs: Determine the required output capacity and product specifications.

2. Evaluate Material Costs: Consider the cost of raw materials and their impact on overall production costs.

3. Consider Automation and Customization: Balance the need for automation and customization with budget constraints.

4. Research Suppliers: Look for reputable suppliers offering competitive pricing and reliable after-sales support.

Optimizing Efficiency in Foam Sheet Extrusion

Optimizing the efficiency of foam sheet extrusion lines involves several strategies:

- Maintain Optimal Conditions: Ensure the right temperature, pressure, and speed settings for each stage of the extrusion process.

- Regular Maintenance: Inspect and clean equipment regularly to prevent blockages and malfunctions.

- Advanced Automation: Invest in automation systems that can adjust production parameters based on real-time feedback and diagnostics[7].

Environmental Considerations

The production and disposal of foam materials, particularly Styrofoam (EPS), pose significant environmental challenges. Styrofoam is non-biodegradable, contributes to pollution, and has limited recycling options. Efforts to reduce Styrofoam use and improve recycling practices are crucial for mitigating these impacts[4].

Future Trends in Foam Sheet Extrusion

The future of foam sheet extrusion will likely involve more sustainable practices, advanced materials, and increased use of digital technologies. Innovations in recycling and waste management will be key to reducing the environmental footprint of foam production. Additionally, the development of new additives and modifiers will enhance the properties of foam materials, expanding their application range[3].

Conclusion

The best foam sheet extrusion equipment price depends on a variety of factors, including production capacity, material type, automation level, and customization options. By understanding these factors and assessing specific production needs, manufacturers can find the most suitable equipment at an optimal price. Whether it's EPE, EPS, XPS, or TPU foam, selecting the right equipment is crucial for achieving high-quality products while maintaining cost efficiency.

FAQ

1. What is the typical price range for EPE foam sheet extrusion equipment?

- The price for EPE foam sheet extruders typically ranges from $45,000 to $150,000, depending on the output capacity and features.

2. How does the cost of EPS foam sheet extrusion equipment compare to EPE?

- EPS foam sheet extrusion machines are generally more expensive, with prices around ₹1,95,00,000 (approximately $250,000 USD) for a 250 kg/hr capacity machine.

3. What factors influence the cost of TPU foam sheet extrusion equipment?

- The cost of TPU foam sheet extruders is influenced by factors such as production capacity, automation level, and customization options, with prices starting from around $50,000.

4. How important is automation in foam sheet extrusion equipment?

- Automation is crucial for maintaining consistency and efficiency in production. Fully automated systems are more expensive but offer significant benefits in terms of product quality and reduced labor costs.

5. What are the key considerations when choosing between different types of foam sheet extrusion equipment?

- Key considerations include production capacity, material type, automation level, and customization options. It's also important to assess the cost of raw materials and the supplier's reputation.

Citations:

[1] https://www.ptonline.com/news/new-pp-foam-extrusion-technology

[2] https://static.prod01.ue1.p.pcomm.net/smeng/user_content/forums/topics/files/1445/762556b9706c09bbd2377f74aa65ec30-fundamentals-of-foam-sheet-extrusion-using-a-tandem-extrusion-line.pdf

[3] https://www.qiangshengplas.com/news/comprehensive-guide-to-pvc-foam-board-extrusion-line-innovations-and-applications/

[4] https://www.e3s-conferences.org/articles/e3sconf/pdf/2024/09/e3sconf_issat2024_07036.pdf

[5] https://www.moldingmachinetepai.com/news/what-are-the-latest-innovations-in-epe-foam-sheet-extrusion-line-technology.html

[6] https://easyengineering.eu/interview-with-alemo/

[7] https://www.moldingmachinetepai.com/news/how-to-optimize-the-efficiency-of-your-epe-foam-sheet-extrusion-line-tips-and-tricks-revealed.html

[8] https://www.tecnaplastics.com/2024/03/06/fap-anticipating-future-trends-in-foam-industry/

[9] https://www.linkedin.com/pulse/global-foam-extrusion-system-market-forecast-zjh4e/

[10] https://www.wevolver.com/article/extruding-plastic

[11] https://4spepublications.onlinelibrary.wiley.com/doi/full/10.1002/pen.25797

[12] https://www.extrusionconsultinginc.com/cost-savings-in-foam-extrusion.html

[13] https://raic.org/product/environmental-impact-extruded-polystyrene-and-other-insulation-used-buildings

[14] https://www.futuremarketinsights.com/reports/foam-market

[15] https://alemo.eu/news/

[16] https://www.useon.cn/resources/Foam-Extrusion_2024_en.pdf

[17] https://www.ptonline.com/articles/tips-and-techniques-boosting-extrusion-productivitypart-iii-of-iii-trim-your-material-energy-costs

[18] https://www.tecnoplastonline.net/fap-minimizing-the-environmental-impact-of-foam-applications/

[19] https://www.marketresearchfuture.com/reports/polyethylene-foam-market-29293

[20] https://xpsa.com/wp-content/uploads/2020/05/Fabian_Hoffee_Herrenbruck_Earthtech_2004.pdf