Content Menu

● Understanding Deflection in Aluminum Extrusions

● Key Features of an Effective Aluminum Extrusion Deflection Calculator

● Popular Aluminum Extrusion Deflection Calculators

>> 1. Maker Hardware's Aluminum Extrusion Deflection Calculator

>> 2. 80/20's Deflection Calculator

>> 3. mk Group Profile Deflection Calculator

● How to Use an Aluminum Extrusion Deflection Calculator

● Visualizing Deflection Calculations

● Importance of Accurate Deflection Calculations

● Factors Affecting Deflection in Detail

>> Material Properties

>> Load Distribution

>> Support Conditions

● Real-World Applications of Aluminum Extrusion Deflection Calculators

● Case Study Example

● Conclusion

● Frequently Asked Questions

>> 1. What is an aluminum extrusion deflection calculator?

>> 2. Why is it important to calculate deflection?

>> 3. What factors influence deflection in aluminum extrusions?

>> 4. Can I use these calculators for different types of loads?

>> 5. How do I interpret the results from a deflection calculator?

Aluminum extrusions are widely used in various industries due to their lightweight, strength, and versatility. However, when designing structures using aluminum extrusions, it is crucial to ensure that they can withstand applied loads without excessive deflection. This is where an aluminum extrusion deflection calculator comes into play. In this article, we will explore what makes a good aluminum extrusion deflection calculator, how to use one effectively, and provide insights into the importance of accurate deflection calculations.

Understanding Deflection in Aluminum Extrusions

Deflection refers to the displacement of a structural member under load. In the case of aluminum extrusions, understanding deflection is vital for ensuring structural integrity and performance. Excessive deflection can lead to structural failure or compromised functionality in applications such as machine frames, conveyor systems, and workstations.

The amount of deflection experienced by an aluminum extrusion depends on several factors:

- Load Type: Point loads versus uniformly distributed loads can significantly affect deflection.

- Extrusion Length: Longer extrusions tend to deflect more under the same load compared to shorter ones.

- Material Properties: The modulus of elasticity of aluminum plays a crucial role in determining how much it will bend under load.

- Support Conditions: The way an extrusion is supported (fixed, pinned, or free) influences its ability to resist bending.

Key Features of an Effective Aluminum Extrusion Deflection Calculator

When looking for the best aluminum extrusion deflection calculator, consider the following features:

- User-Friendly Interface: A good calculator should be easy to navigate, allowing users to input parameters without confusion.

- Multiple Load Scenarios: It should accommodate various loading conditions such as point loads and uniformly distributed loads.

- Profile Selection: The ability to choose from a range of extrusion profiles ensures that users can accurately assess their specific application needs.

- Real-Time Calculations: Instant feedback on calculations helps users make quick decisions during the design process.

- Detailed Output: The calculator should provide comprehensive results including moment of inertia, yield strength, and maximum allowable loads.

Popular Aluminum Extrusion Deflection Calculators

Several online tools stand out for their effectiveness in calculating aluminum extrusion deflection:

1. Maker Hardware's Aluminum Extrusion Deflection Calculator

Maker Hardware offers a straightforward tool that allows users to select extrusion profiles and input parameters such as length and load type. It calculates deflection for various loading scenarios and displays results instantly. This calculator is particularly useful for beginners due to its simple interface.

2. 80/20's Deflection Calculator

80/20 provides a robust deflection calculator that allows users to choose profile types and input specific loads. It supports multiple configurations (fixed ends, supported ends) and gives detailed engineering specifications. This tool is ideal for those who need comprehensive data for engineering assessments.

3. mk Group Profile Deflection Calculator

This tool from mk Group enables users to calculate deflections based on different load scenarios. It is designed for professionals who require precise calculations for complex projects involving aluminum profiles.

How to Use an Aluminum Extrusion Deflection Calculator

Using an aluminum extrusion deflection calculator typically involves the following steps:

1. Select the Extrusion Profile: Choose the specific aluminum profile you are working with from a predefined list.

2. Input Length: Enter the length of the extrusion in millimeters or inches as required by the tool.

3. Choose Load Type: Specify whether you are applying a point load or a uniformly distributed load.

4. Enter Load Value: Input the expected load in kilograms or pounds, depending on the calculator's requirements.

5. Calculate Deflection: Click on the calculate button to obtain results, which will include deflection values based on your inputs.

6. Analyze Results: Review the output carefully, noting any recommendations regarding maximum allowable loads or adjustments needed for your design.

Visualizing Deflection Calculations

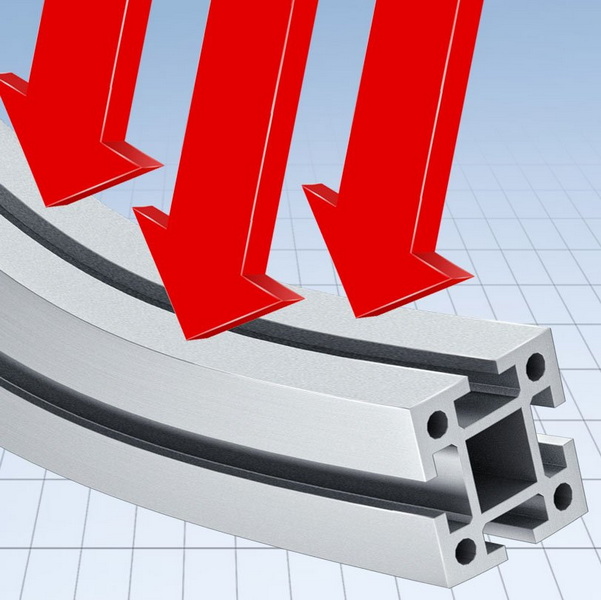

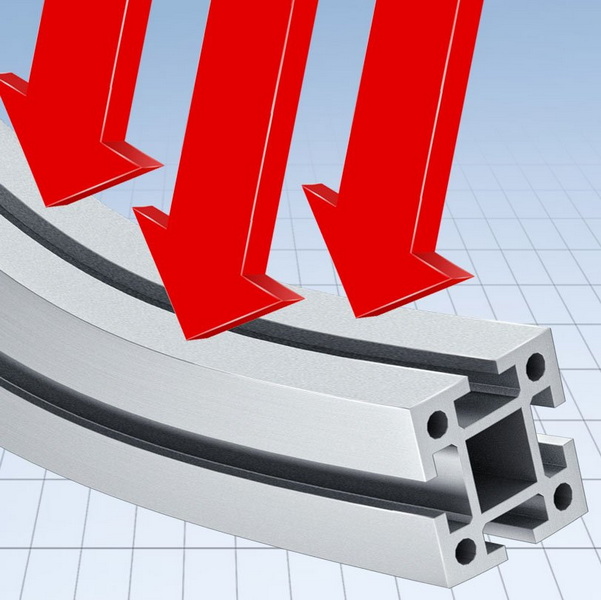

To enhance understanding, incorporating visuals such as diagrams showing how loads affect aluminum extrusions can be beneficial. For example:

Deflection Diagram

"Figure 1: Illustration of how different loads affect an aluminum extrusion."

Additionally, videos demonstrating how to use these calculators can provide practical insights:

Using the 80/20 Deflection Calculator

"Figure 2: Video tutorial on using the 80/20 Deflection Calculator."

Importance of Accurate Deflection Calculations

Accurate deflection calculations are critical for several reasons:

- Safety: Ensuring that structures do not exceed acceptable deflection limits prevents potential failures that could endanger users or equipment.

- Performance: Properly calculated designs enhance the functionality of machinery and structures by maintaining alignment and operational efficiency.

- Cost Efficiency: By selecting appropriate profiles based on accurate calculations, companies can avoid over-engineering or under-engineering their solutions, leading to cost savings in materials and labor.

Factors Affecting Deflection in Detail

To fully grasp how an aluminum extrusion behaves under load, it's essential to delve deeper into the factors influencing deflection:

Material Properties

The mechanical properties of aluminum play a significant role in its performance under load. The modulus of elasticity (E) indicates how much a material will deform under stress; higher values mean less deformation. Additionally, yield strength determines when a material will permanently deform rather than return to its original shape after removing the load.

Load Distribution

Understanding how loads are applied is crucial for accurate calculations:

- Point Loads: Concentrated at a single point along the beam's length; these create maximum bending moments at their location.

- Distributed Loads: Spread evenly across a length; these result in lower maximum bending moments but affect larger areas of the beam.

Support Conditions

The way an extrusion is supported significantly affects its deflection characteristics:

- Simply Supported Beam: Free at both ends; it experiences maximum deflection at mid-span.

- Fixed Beam: Restrained at both ends; this configuration reduces overall deflection compared to simply supported beams.

- Cantilever Beam: Fixed at one end; it experiences maximum deflection at the free end due to its unsupported nature.

Real-World Applications of Aluminum Extrusion Deflection Calculators

In practice, engineers frequently utilize aluminum extrusion deflection calculators across various industries:

- Manufacturing Equipment: In machine design, ensuring that frames can support operational loads without excessive flexing is critical for precision manufacturing processes.

- Construction Projects: In building applications, accurate calculations help ensure that structural components meet safety codes and performance standards.

- Automotive Industry: Lightweight yet strong materials are essential for vehicle performance; thus, accurate modeling of component behavior under stress is vital.

Case Study Example

Consider a scenario where an engineer is designing a conveyor system using aluminum extrusions. The engineer selects a specific profile with known properties and inputs parameters into an online calculator:

1. Length of 2000 mm.

2. A point load of 150 kg applied at mid-span.

3. Supports are simply fixed at both ends.

Upon calculation, the output indicates a maximum deflection of 5 mm—within acceptable limits for operational efficiency but close enough that further reinforcement may be considered if additional loads are anticipated during operation.

Conclusion

Choosing the right aluminum extrusion deflection calculator is essential for engineers and designers working with aluminum profiles. Tools like those offered by Maker Hardware, 80/20, and mk Group provide valuable resources for ensuring that designs meet safety and performance standards. By understanding how to effectively use these calculators and recognizing the importance of accurate deflection calculations, professionals can optimize their projects for success while ensuring safety and reliability in their designs.

Frequently Asked Questions

1. What is an aluminum extrusion deflection calculator?

An aluminum extrusion deflection calculator is a tool used to determine how much an aluminum profile will bend under specific loads based on its dimensions and material properties.

2. Why is it important to calculate deflection?

Calculating deflection is crucial for ensuring structural integrity, safety, and performance in applications using aluminum extrusions.

3. What factors influence deflection in aluminum extrusions?

Deflection in aluminum extrusions is influenced by load type (point vs. distributed), length of the extrusion, material properties (modulus of elasticity), support conditions (fixed or pinned), and profile geometry.

4. Can I use these calculators for different types of loads?

Yes, most calculators allow you to choose between different loading scenarios such as point loads or uniformly distributed loads.

5. How do I interpret the results from a deflection calculator?

Results typically include the amount of expected deflection along with recommendations regarding maximum allowable loads based on industry standards or safety factors.