Content Menu

● Introduction to Aluminum Extruders

>> Benefits of Aluminum Extruders

>> Types of Extruders

● Choosing the Best Aluminum Extruder

● Popular Aluminum Extruders

● Upgrading to an Aluminum Extruder

● Troubleshooting Common Extruder Issues

● Conclusion

● FAQ

>> 1. What are the primary benefits of using an aluminum extruder in 3D printing?

>> 2. How do I choose the best aluminum extruder for my printer?

>> 3. What are the common issues with extruders in 3D printing?

>> 4. Can I upgrade my existing extruder to an aluminum one?

>> 5. Are aluminum extruders compatible with all types of filaments?

● Citations:

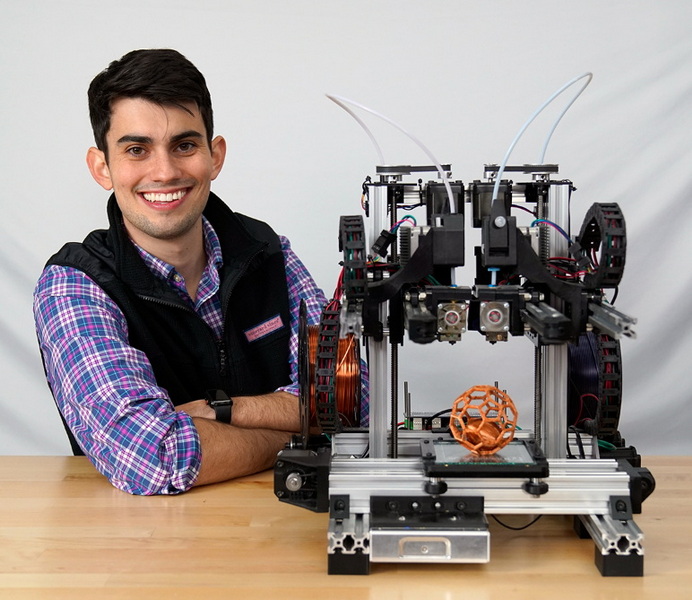

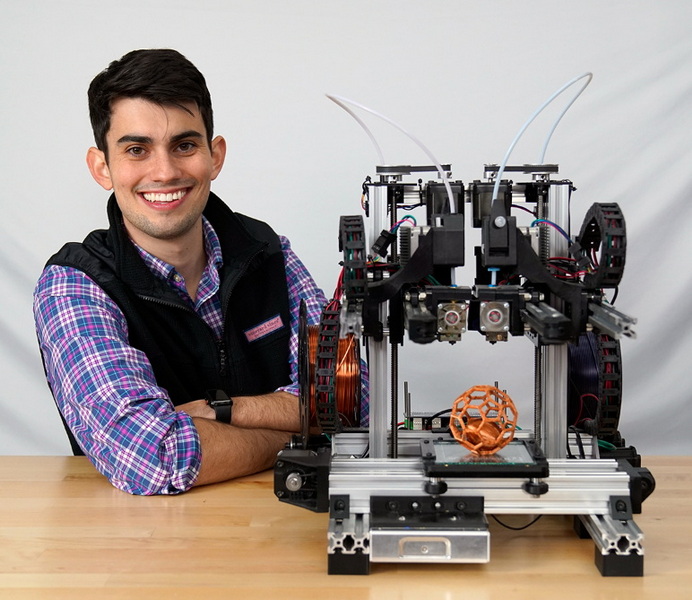

In the realm of 3D printing, the extruder plays a crucial role in determining the quality and precision of the prints. Among various materials used for extruders, aluminum stands out due to its exceptional strength-to-weight ratio, durability, and thermal conductivity. This article delves into the world of aluminum extruders, exploring their benefits, types, and how to choose the "best aluminum extruder" for high-quality 3D printing.

Introduction to Aluminum Extruders

Aluminum extruders have become increasingly popular in 3D printing due to their ability to enhance print quality and reliability. Unlike plastic extruders, aluminum models offer better thermal management and mechanical stability, which are essential for consistent filament feeding and precise control over material deposition.

Benefits of Aluminum Extruders

1. Lightweight and Strong: Aluminum extruders are lightweight, reducing the overall weight of the moving parts of the printer. This allows for faster movements and higher print speeds, especially beneficial in Bowden extruder setups where minimizing weight on the print head is crucial[4].

2. Improved Stability: Despite being lightweight, aluminum provides sufficient strength to maintain the stability of the extruder assembly, minimizing vibrations during printing. This stability is essential for achieving high-quality prints with accurate dimensional tolerances[4].

3. Durability and Wear Resistance: Aluminum extruders exhibit excellent durability and resistance to wear and tear. The inherent hardness of aluminum allows it to withstand prolonged use without significant degradation, particularly beneficial for the gears and moving parts within the extruder mechanism[4].

4. Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, making it highly resistant to corrosion. This ensures that the extruder maintains its structural integrity and performance even in environments with varying humidity levels[4].

5. Thermal Conductivity: Aluminum's excellent thermal conductivity helps dissipate heat generated by the extruder's motor and friction, preventing heat creep and potential clogging issues. This is particularly important when printing with temperature-sensitive filaments like PLA[4].

Types of Extruders

There are generally two main types of extruders used in 3D printing:

- Direct Drive Extruders: These mount the extruder motor and feeding mechanism directly on top of the hot end. This configuration minimizes the distance the filament has to travel, offering better control, especially with flexible filaments[4].

- Bowden Extruders: In this setup, the extruder motor is located remotely, typically on the printer frame, and the filament is fed to the hot end through a PTFE (Teflon) tube. Bowden extruders reduce the weight on the moving print head, allowing for faster printing speeds but may require more retraction tuning[4].

Choosing the Best Aluminum Extruder

When selecting the best aluminum extruder for your 3D printing needs, several factors should be considered:

1. Compatibility: Ensure the extruder is compatible with your printer model and the types of filaments you plan to use. Aluminum extruders are generally versatile, supporting a wide range of materials including PLA, ABS, PETG, TPU, and nylon[4].

2. Design and Build Quality: Look for extruders with robust designs that minimize vibrations and ensure consistent filament feeding. Advanced gear designs, such as dual-drive mechanisms, provide a more secure grip on the filament, reducing slippage and improving print quality[4].

3. Thermal Management: Opt for extruders with good thermal management features. Aluminum's natural heat sink capability helps maintain stable operating temperatures, crucial for preventing heat-related issues during printing[4].

4. Cost-Effectiveness: Aluminum extruders offer a cost-effective solution compared to other materials like stainless steel or titanium. They are durable, reducing the need for frequent replacements and minimizing overall costs[4].

Popular Aluminum Extruders

Several aluminum extruders are highly regarded in the 3D printing community:

- Creality Ender Series: Known for their robust aluminum extruders, these printers provide reliable filament feeding and consistent print quality. The aluminum extruder upgrade for the Ender 3 V2 is a popular modification among enthusiasts[4].

- Prusa i3 Series: The Prusa i3 MK3S+ features a well-designed aluminum extruder that contributes to its reputation for precision and dependability[4].

- Dyzextruder Pro: This high-performance extruder is designed for advanced 3D printing applications, featuring an all-metal design for durability and heat resistance[4].

Upgrading to an Aluminum Extruder

Upgrading your 3D printer with an aluminum extruder can significantly enhance its performance. Here's a step-by-step guide on how to install an all-metal aluminum extruder on a Creality Ender 3 V2:

1. Prepare the Tools and Components: Ensure you have all necessary tools and components, including the aluminum extruder, screws, and any additional hardware required for the upgrade.

2. Remove the Stock Extruder: Carefully disassemble and remove the stock plastic extruder from your printer.

3. Install the Aluminum Extruder: Mount the aluminum extruder according to the manufacturer's instructions. This typically involves attaching it to the printer frame and connecting it to the hot end.

4. Configure the Settings: Adjust your printer's settings to optimize performance with the new extruder. This may include calibrating the extruder steps per mm and adjusting retraction settings.

Troubleshooting Common Extruder Issues

When using an aluminum extruder, you might encounter some common issues:

- Under-Extrusion: This occurs when inadequate material flows out of the nozzle. Check for obstructions, ensure proper nozzle heating, and adjust the extrusion multiplier in your slicer software[5][8].

- Over-Extrusion: Too much material is extruded, causing excess plastic buildup. Adjust the extrusion multiplier and ensure correct filament diameter settings[5][8].

- Filament Slipping: If the filament slips from the drive gear, check the gear tension and ensure the filament is properly seated[7].

Conclusion

Choosing the best aluminum extruder for your 3D printing needs can significantly enhance the quality and reliability of your prints. Aluminum extruders offer a combination of strength, durability, and thermal management that makes them ideal for high-quality printing applications. By understanding the benefits and considerations of aluminum extruders, you can optimize your printer's performance and unlock new possibilities in 3D printing.

FAQ

1. What are the primary benefits of using an aluminum extruder in 3D printing?

Aluminum extruders offer improved stability, durability, and thermal conductivity, which enhance print quality and reliability. They are also lightweight, allowing for faster print speeds[4].

2. How do I choose the best aluminum extruder for my printer?

Consider compatibility with your printer model, design quality, thermal management features, and cost-effectiveness. Ensure it supports the types of filaments you plan to use[4].

3. What are the common issues with extruders in 3D printing?

Common issues include under-extrusion, over-extrusion, and filament slippage. These can be addressed by adjusting settings, ensuring proper gear tension, and clearing obstructions[5][7].

4. Can I upgrade my existing extruder to an aluminum one?

Yes, upgrading to an aluminum extruder is possible and can significantly improve print quality. Follow manufacturer instructions for installation and adjust settings as needed[3][4].

5. Are aluminum extruders compatible with all types of filaments?

Aluminum extruders are generally compatible with a wide range of filaments, including PLA, ABS, PETG, TPU, and nylon. However, always check compatibility with your specific printer model[4].

Citations:

[1] https://jlcmc.com/blog/optimizing-aluminum-extrusion-frames-for-enhanced-3d-printing-accuracy

[2] https://3dprintingcanada.com/collections/aluminum-extrusion-v-slot

[3] https://www.youtube.com/watch?v=UtemZqFJ5rY

[4] https://www.yjing-extrusion.com/why-should-you-choose-an-aluminum-extruder-for-3d-printing.html

[5] https://qidi3d.com/blogs/news/3d-printing-troubleshooting-guide

[6] https://pick3dprinter.com/aluminum-3d-printer/

[7] https://www.artillery3d.com/blogs/3d-printer-user-guide/common-issues-and-solutions-for-extruders-in-fdm-3d-printing

[8] https://additive-x.com/blog/7-common-3d-printing-problems-with-solutions

[9] https://www.instructables.com/Failed-3D-Prints-And-How-To-Fix-Them/

[10] https://www.robotshop.com/collections/aluminum-extrusions-3d-printers