Content Menu

● Understanding Pipe Extrusion Equipment

>> Key Components of Pipe Extrusion Equipment

● Factors Influencing the Price of High-Quality Pipe Extrusion Equipment

>> 1. Machine Type and Configuration

>> 2. Production Capacity

>> 3. Automation and Technology Features

>> 4. Material Handling and Compatibility

>> 5. Size and Dimensions of Pipes Produced

>> 6. Brand, Origin, and After-Sales Service

● Average Price Ranges for High-Quality Pipe Extrusion Equipment

>> Examples from Market Listings

● How to Choose the Right Pipe Extrusion Equipment Within Your Budget

>> Assess Your Production Needs

>> Evaluate Supplier Reputation and Support

>> Consider Long-Term Operational Costs

● Maintenance and Longevity Considerations

● Conclusion

● FAQ

>> 1. What is the typical price range for high-quality pipe extrusion equipment?

>> 2. How does production capacity affect the price of pipe extrusion machines?

>> 3. What materials can be processed with pipe extrusion machines?

>> 4. What are the benefits of choosing a machine with higher automation?

>> 5. How important is after-sales service when purchasing pipe extrusion equipment?

● Citations:

Pipe extrusion equipment is a critical investment for manufacturers producing plastic pipes used in construction, agriculture, water supply, and industrial applications. Understanding the average price for high-quality pipe extrusion equipment is essential for businesses planning to enter or expand in this market. This comprehensive article explores the factors influencing the cost, typical price ranges, and considerations for selecting the right equipment. It also includes a detailed FAQ section to address common questions.

Understanding Pipe Extrusion Equipment

Pipe extrusion machines transform raw plastic materials such as PVC, HDPE, PP, and other polymers into continuous lengths of pipe through a process involving melting, shaping, cooling, and cutting. These machines vary widely in capacity, complexity, and automation level, which directly impacts their price.

Key Components of Pipe Extrusion Equipment

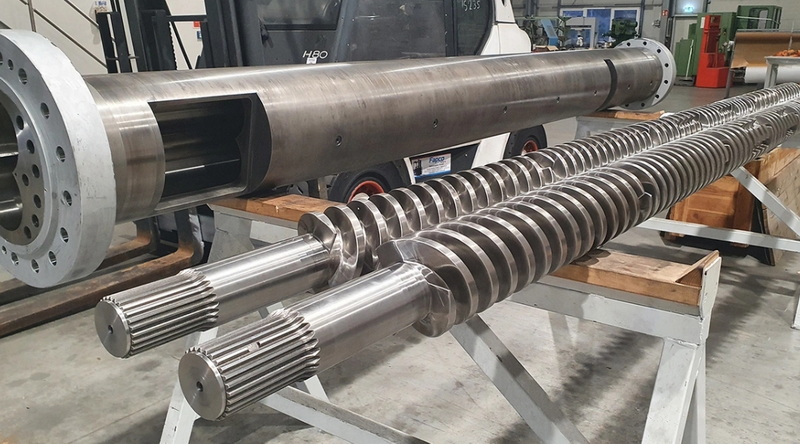

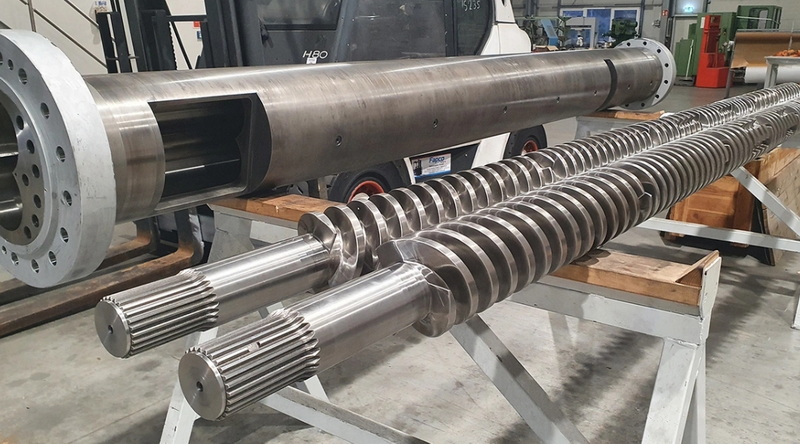

- Extruder: Melts and mixes the plastic material.

- Screw and Barrel: Convey and process the molten plastic.

- Die Head: Shapes the molten plastic into pipe form.

- Cooling System: Solidifies the pipe to maintain shape and dimensions.

- Haul-Off Unit: Pulls the pipe at a controlled speed.

- Cutting or Winding Unit: Cuts pipes to length or winds them for storage.

The sophistication and quality of each component influence the overall equipment price and production efficiency[10].

Factors Influencing the Price of High-Quality Pipe Extrusion Equipment

1. Machine Type and Configuration

- Single Screw vs. Twin Screw Extruders: Single screw machines are generally less expensive and suitable for simpler extrusion processes. Twin screw extruders offer better mixing and adaptability, especially for complex materials, but come at a higher cost[4][6].

- Co-extrusion Capability: Machines capable of producing multi-layer pipes with different materials are more advanced and costly[10][13].

2. Production Capacity

The output capacity, often measured in kilograms per hour (kg/h), significantly affects price. Higher capacity machines require more powerful motors and robust components, increasing costs. For example, machines with capacities ranging from 50 kg/h to over 1000 kg/h are available, with prices scaling accordingly[4][5][13].

3. Automation and Technology Features

- Advanced control systems such as PLC touchscreen panels, automated temperature control, and energy-efficient motors increase the price but improve production consistency and reduce labor costs[4][8].

- Machines with higher automation levels tend to be more expensive but offer better efficiency and quality control[13].

4. Material Handling and Compatibility

Machines designed to process a wide range of materials or special high-performance plastics may require customized features, increasing the price[4][5].

5. Size and Dimensions of Pipes Produced

Larger diameter pipe extrusion lines are more expensive due to the complexity of the die, cooling systems, and haul-off units required[1][8].

6. Brand, Origin, and After-Sales Service

Reputable manufacturers with certifications such as ISO and CE tend to price their equipment higher, reflecting quality assurance and better after-sales support[5][6].

Average Price Ranges for High-Quality Pipe Extrusion Equipment

Based on market data from leading manufacturers and suppliers, here is an overview of typical price ranges for high-quality pipe extrusion equipment as of 2025:

| Price Range (USD) | Description | Capacity & Features |

| $18,000 - $40,000 | Entry-level to medium capacity machines | Suitable for small to medium pipe diameters, basic automation129 |

| $40,000 - $90,000 | Medium to high capacity, more automation | Larger diameters, advanced control systems, some customization138 |

| $90,000 - $200,000+ | Premium, fully customized, high-capacity lines | Multi-layer co-extrusion, large diameter pipes, full automation, high output14813 |

Examples from Market Listings

- Plastic pipe extrusion lines from Zhangjiagang Chenxing Machinery Co., Ltd. are priced around $28,000 per set for high-quality models[1].

- Zhangjiagang Sunrise Machinery Co., Ltd. offers machines ranging from $25,000 to $75,000 depending on specifications[1].

- Premium extrusion lines with advanced features can cost between $100,000 and $150,000 or more, such as those from Yurefon Machinery[1][8].

- Indian manufacturers offer PVC pipe extrusion machines in the range of ₹10,00,000 to ₹46,50,000 (approximately $12,000 to $55,000), depending on capacity and automation[2][12].

How to Choose the Right Pipe Extrusion Equipment Within Your Budget

Assess Your Production Needs

- Define the pipe diameter range and output capacity required.

- Consider the types of plastic materials you need to process.

- Evaluate the level of automation that fits your operational capabilities and budget[5][10].

Evaluate Supplier Reputation and Support

- Choose suppliers with proven experience and certifications.

- Ensure availability of after-sales service, technical support, and spare parts[5].

Consider Long-Term Operational Costs

- Energy efficiency and maintenance requirements impact overall cost-effectiveness.

- Higher initial investment in advanced technology can reduce downtime and labor costs[4][7].

Maintenance and Longevity Considerations

Maintaining high-quality pipe extrusion equipment is crucial to protect your investment. Regular inspection, cleaning, lubrication, and calibration ensure consistent performance and extend machine life[7][10].

Conclusion

The average price for high-quality pipe extrusion equipment varies widely based on machine type, capacity, automation level, and customization. Entry-level machines start around $18,000, while premium, fully automated lines can exceed $150,000. Selecting the right equipment requires balancing production needs, budget, and long-term operational efficiency. Investing in reputable manufacturers and proper maintenance will maximize your return and ensure consistent, high-quality pipe production.

FAQ

1. What is the typical price range for high-quality pipe extrusion equipment?

High-quality pipe extrusion equipment prices typically range from $18,000 for basic models to over $150,000 for premium, fully automated, and customized machines[1][4][8].

2. How does production capacity affect the price of pipe extrusion machines?

Higher production capacity requires more powerful motors and complex components, increasing the price. Machines with capacities from 50 kg/h to over 1000 kg/h are available, with prices scaling accordingly[4][5][13].

3. What materials can be processed with pipe extrusion machines?

Common materials include PVC, HDPE, PP, and LDPE. Some machines can handle specialized materials or multi-layer co-extrusion for enhanced pipe properties[10][13].

4. What are the benefits of choosing a machine with higher automation?

Higher automation improves production consistency, reduces labor costs, and enhances energy efficiency, though it increases the initial investment[4][8].

5. How important is after-sales service when purchasing pipe extrusion equipment?

After-sales service is critical for technical support, spare parts availability, and maintenance, which help minimize downtime and extend machine life[5][13].

Citations:

[1] https://www.made-in-china.com/products-search/hot-china-products/Plastic_Pipe_Extrusion_Line_Price.html

[2] https://dir.indiamart.com/impcat/pvc-pipe-extrusion-machine.html

[3] https://www.made-in-china.com/products-search/hot-china-products/Extrusion_Machine_Price.html

[4] https://plastic-extrusionmachines.com/plastic-extrusion-machine-cost/

[5] https://machine.goldsupplier.com/blog/hdpe-pipe-extrusion-machine/

[6] https://www.sourcifychina.com/pipe-extrusion-machine-guide-in-depth/

[7] https://www.polestar-machinery.com/news/essential-maintenance-tips-for-pe-extrusion-lines/

[8] https://deltaplastik.com/blog/plastic-extrusion-machine-prices-2024-choosing-the-right-machine-for-your-needs

[9] https://faygoplast.en.alibaba.com/productgrouplist-212194291/Plastic_Pipe_Extrusion_Line.html?spm=a2700.icbuShop.prup15aafb.10.5f34487dTv5cO7

[10] https://www.caisumachinery.com/what-is-a-pipe-extrusion-machine-a-complete-guide/

[11] https://www.friendplasticmachine.com/sale-10884614-50-110-hdpe-pipe-extrusion-line-hdpe-pipe-making-machine-high-productivity.html

[12] https://www.uniquemachinery.co.in/pvc-pipe-machine.html

[13] https://machine.goldsupplier.com/hdpe-pipe-extrusion-machine/

[14] https://qsplasticmachine.en.made-in-china.com/product-group/foFTiLzdnPWq/PE-Pipe-Extrusion-Line-1.html

[15] https://www.alibaba.com/showroom/upvc-pipe-extrusion-machine.html

[16] https://www.friendplasticmachine.com/sale-10166874-250mm-pe-pvc-hdpe-plastic-pipe-extrusion-machine-100-250kg-h-capacity.html

[17] https://www.polestar-machinery.com/pricelist-for-hdpe-pipe-extrusion-machine-16-2000mm-pe-pipe-extrusion-line-polestar-product/

[18] https://www.alibaba.com/showroom/plastic-pipe-extrusion-machine.html

[19] https://www.caisumachinery.com/what-is-a-pipe-extrusion-machine-a-complete-guide/

[20] https://www.gracepm.com/pricelist-for-pvc-pipe-extrusion-line-4-cavities-stone-paper-extrusion-line-grace-product/

[21] https://www.made-in-china.com/products-search/hot-china-products/Pipe_Extrusion_Equipments_Price.html

[22] https://m.extruders-machine.com/sale-13727708-big-size-pe-pipe-extrusion-machine-with-single-screw-extruder-sj160-33.html

[23] https://www.polestar-machinery.com/pricelist-for-hdpe-pipe-extrusion-machine-pvc-pipe-connection-machinethreading-machine-polestar-product/

[24] https://www.alibaba.com/showroom/pvc-pipe-extrusion-machine.html

[25] https://www.alibaba.com/product-detail/HDPE-Double-Wall-Corrugated-Pipe-production_1601261649695.html

[26] https://www.alibaba.com/product-detail/High-quality-PVC-pipe-extrusion-extruding_1601251359669.html

[27] https://www.alibaba.com/product-detail/High-Quality-Rigid-Pvc-Pipe-Extrusion_11000019484571.html

[28] https://www.twinscrew.net/en/article/How-to-Choose-the-Best-PVC-Pipe-Extrusion-Line.html

[29] https://www.adremac.com/pipe-extruders-comprehensive-guide-to-technology-applications-and-innovations-in-plastic-pipe-manufacturing/

[30] https://www.blesson.cn/faqs/

[31] https://www.friendplasticmachine.com/quality-10166874-250mm-pe-pvc-hdpe-plastic-pipe-extrusion-machine-100-250kg-h-capacity

[32] https://www.linkedin.com/pulse/analyzing-plastic-extruder-machine-price-beyond-purchase-andrea-chan-haqge

[33] https://www.linkedin.com/pulse/key-buying-pipe-extrusion-machinery-important-factors-nader-amin

[34] https://www.linkedin.com/pulse/10-frq-pipe-extruder-line-megan-jwell-jwell-machinery-

[35] http://www.chinaextruders.com/m/article/mojmFqLp6gSj.html

[36] https://www.sourcifychina.com/top-pipe-extrusion-machine-manufacturer-compare/