Content Menu

● Introduction to Polymer Extrusion Equipment

>> Key Components of Polymer Extrusion Equipment

● Types of Polymer Extrusion Equipment

>> Single Screw Extruders

>> Twin Screw Extruders

>> Conical Twin Screw Extruders

● Pricing of Polymer Extrusion Equipment in China

>> Factors Influencing Pricing

● China Polymer Extrusion Equipment Quotes

>> How to Obtain Quotes

● Market Trends and Future Developments

● Case Studies: Successful Implementations

● Conclusion

● Frequently Asked Questions

>> 1. What are the main types of polymer extrusion equipment?

>> 2. How do I choose the right polymer extrusion equipment for my business?

>> 3. What influences the pricing of polymer extrusion equipment?

>> 4. Can polymer extrusion equipment be customized?

>> 5. What are the benefits of using Chinese polymer extrusion equipment?

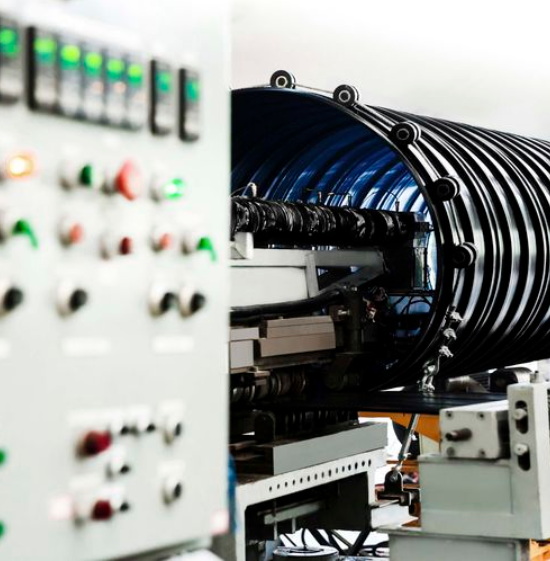

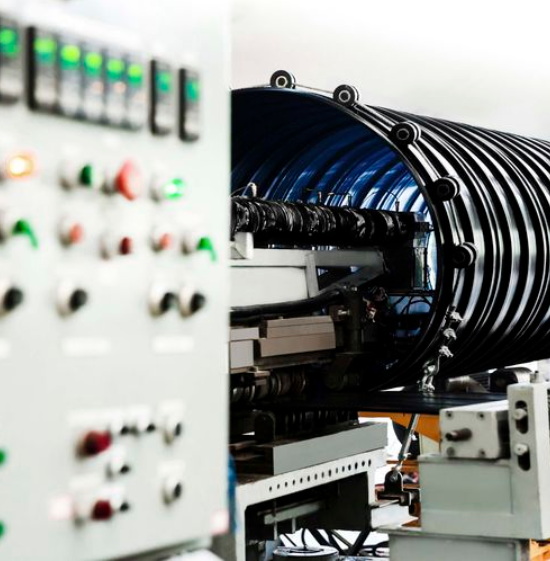

Polymer extrusion equipment is a crucial component in the manufacturing process of various plastic products, including pipes, profiles, sheets, and more. China, being a global leader in plastic production, offers a wide range of polymer extrusion equipment with varying prices based on specifications and applications. This article will delve into the average prices of polymer extrusion equipment in China, explore the different types of equipment available, and discuss factors influencing their pricing.

Introduction to Polymer Extrusion Equipment

Polymer extrusion involves shaping raw plastic materials into desired forms using specialized machinery. The process typically involves feeding plastic granules into a hopper, melting them in a barrel using heat and shear, and then forcing the molten plastic through a die to achieve the desired shape. The equipment used in this process can vary significantly in terms of design, functionality, and technological advancements.

Key Components of Polymer Extrusion Equipment

1. Hopper: Holds the raw plastic materials.

2. Barrel: Houses the screw and withstands high pressures and temperatures.

3. Screw: Transports, melts, and mixes the plastic.

4. Die: Shapes the molten plastic into the desired profile.

5. Cooling System: Solidifies the extruded plastic.

The design and quality of these components play a significant role in determining the efficiency and output of the extrusion process.

Types of Polymer Extrusion Equipment

Single Screw Extruders

Single screw extruders are the most common type, suitable for a wide range of applications due to their simplicity and cost-effectiveness. They are ideal for producing products like PVC pipes and PE sheets. Single screw extruders are generally less expensive than twin screw models but may not offer the same level of mixing and compounding capabilities.

Twin Screw Extruders

Twin screw extruders offer better mixing and compounding capabilities, making them suitable for complex materials like recycled PET flakes. They are more versatile and can handle a broader range of plastic materials. Twin screw extruders are often used in applications requiring precise control over material flow and mixing, such as in the production of high-quality plastic compounds.

Conical Twin Screw Extruders

Conical twin screw extruders are used for specific applications requiring precise control over material flow and mixing. They are less common but offer unique advantages in certain processes, particularly where space is limited or specific material properties need to be achieved.

Pricing of Polymer Extrusion Equipment in China

The prices of polymer extrusion equipment in China vary widely based on the type, capacity, and features of the machine. Here are some general price ranges:

- Single Screw Extruders: Prices can range from US$ 6,000 to US$ 120,000 depending on the capacity and application.

- Twin Screw Extruders: Generally more expensive, with prices starting from US$ 30,000 and going up to US$ 300,000 or more for high-capacity models.

- Conical Twin Screw Extruders: These are typically priced higher due to their specialized design, often above US$ 100,000.

Factors Influencing Pricing

1. Capacity: Higher production capacities increase the price.

2. Material Compatibility: Machines capable of handling a wide range of materials are more expensive.

3. Customization: Tailored solutions for specific applications can significantly raise costs.

4. Brand and Quality: Reputable brands with high-quality components command higher prices.

5. Technology and Automation: Advanced automation and control systems can also impact pricing.

China Polymer Extrusion Equipment Quotes

When seeking quotes for polymer extrusion equipment in China, it's essential to consider the following:

- Supplier Reputation: Look for audited suppliers with a history of delivering quality products.

- Customization Options: Ensure the supplier can meet your specific needs.

- After-Sales Support: Reliable service and maintenance support are crucial for long-term operation.

How to Obtain Quotes

1. Contact Multiple Suppliers: Reach out to several suppliers to compare prices and services.

2. Specify Requirements: Clearly outline your production needs and specifications.

3. Evaluate Responses: Assess each supplier's ability to meet your requirements and provide support.

Market Trends and Future Developments

The polymer extrusion equipment market is evolving rapidly, driven by technological advancements and increasing demand for sustainable and efficient production processes. Trends include:

- Sustainability: There is a growing focus on using recycled materials and reducing energy consumption.

- Digitalization: Integration of advanced automation and IoT technologies to enhance efficiency and monitoring.

- Customization: Increased demand for tailored solutions to meet specific product requirements.

These trends are expected to influence pricing and availability of polymer extrusion equipment in the future.

Case Studies: Successful Implementations

Several companies have successfully implemented polymer extrusion equipment in China, achieving significant improvements in production efficiency and product quality. For example, a leading PVC pipe manufacturer in China upgraded to a high-capacity twin screw extruder, resulting in a 30% increase in production volume and a 20% reduction in energy costs.

Conclusion

The average price for polymer extrusion equipment in China depends on several factors, including the type of extruder, production capacity, and customization requirements. By understanding these factors and exploring different suppliers, businesses can find the best value for their specific needs. The market is dynamic, with ongoing advancements in technology and sustainability, which will continue to shape the industry's future.

Frequently Asked Questions

1. What are the main types of polymer extrusion equipment?

Answer: The main types include single screw extruders, twin screw extruders, and conical twin screw extruders. Each type is suited for different applications based on material complexity and production requirements.

2. How do I choose the right polymer extrusion equipment for my business?

Answer: Consider factors such as production capacity, material compatibility, customization options, and supplier reputation. It's also important to evaluate the cost-effectiveness and after-sales support provided by the supplier.

3. What influences the pricing of polymer extrusion equipment?

Answer: Pricing is influenced by factors like production capacity, material compatibility, customization options, and the brand's reputation. Higher capacities and more complex designs typically increase the cost.

4. Can polymer extrusion equipment be customized?

Answer: Yes, polymer extrusion equipment can be customized to meet specific application needs. This includes customizing the extruder design, die shapes, and control systems to optimize production for particular products.

5. What are the benefits of using Chinese polymer extrusion equipment?

Answer: Chinese polymer extrusion equipment offers advantages such as competitive pricing, advanced technology, and a wide range of customization options. Additionally, many Chinese suppliers provide comprehensive after-sales support and maintenance services.