Content Menu

● Understanding Aluminum Extrusion CNC Machines

● Average Costs of Aluminum Extrusion CNC Machines

● Factors Influencing the Cost of Aluminum Extrusion CNC Machines

● Key Features of Aluminum Extrusion CNC Machines

● Applications of Aluminum Extrusion CNC Machines

>> Cost Comparison with Other Manufacturing Processes

● Maintenance Considerations

● Future Trends in Aluminum Extrusion Technology

● Conclusion

● FAQ

>> 1. What is the lifespan of an aluminum extrusion CNC machine?

>> 2. How much does maintenance cost for these machines?

>> 3. Can I finance an aluminum extrusion CNC machine?

>> 4. What materials can be processed besides aluminum?

>> 5. Is training available for operating these machines?

Aluminum extrusion CNC machines are essential tools in modern manufacturing, allowing for the precise shaping and cutting of aluminum profiles. As the demand for aluminum products continues to rise across various industries, understanding the costs associated with these machines becomes crucial for manufacturers. In this article, we will explore the average cost of aluminum extrusion CNC machines, the factors influencing these costs, and provide insights into their features and applications.

Understanding Aluminum Extrusion CNC Machines

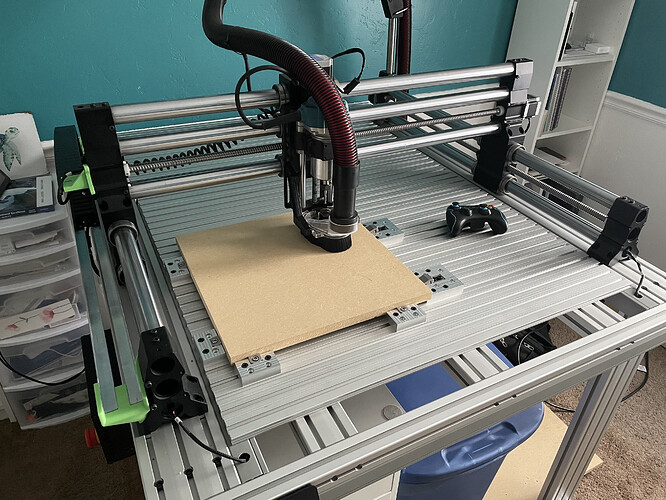

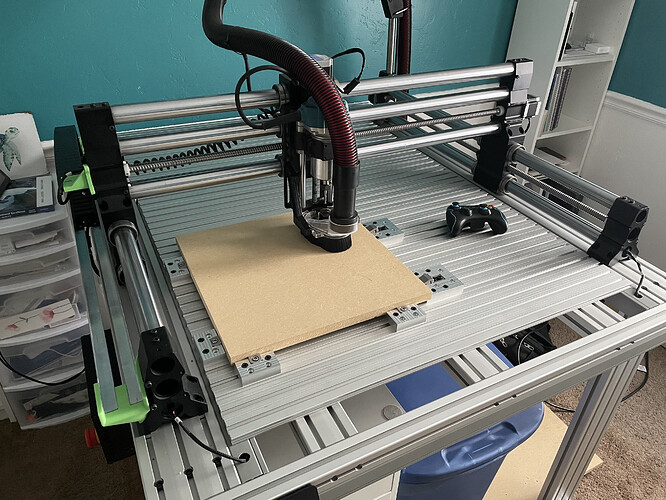

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into a desired cross-sectional profile by forcing it through a die. This process is widely used due to aluminum's lightweight, strength, and resistance to corrosion. CNC (Computer Numerical Control) machines enhance this process by automating the cutting and shaping tasks, ensuring high precision and efficiency.

The CNC technology allows for complex shapes to be produced with minimal human intervention, reducing the risk of errors and increasing production speed. This automation is especially beneficial in high-volume production environments where consistency is key.

Average Costs of Aluminum Extrusion CNC Machines

The cost of aluminum extrusion CNC machines can vary significantly based on several factors, including machine size, capabilities, brand, and additional features. Here's a breakdown of typical price ranges:

- Entry-Level Machines: $10,000 - $30,000

These machines are suitable for small-scale operations or hobbyists. They often have limited capabilities but can handle basic extrusion tasks.

- Mid-Range Machines: $30,000 - $100,000

These machines offer more advanced features such as larger cutting areas and better precision. They are ideal for medium-sized businesses looking to increase productivity.

- High-End Machines: $100,000 - $500,000+

High-end CNC machines come equipped with state-of-the-art technology, allowing for complex machining tasks and high-volume production. These are typically used by large manufacturers who require efficiency and precision in their operations.

Factors Influencing the Cost of Aluminum Extrusion CNC Machines

Several factors can affect the overall cost of an aluminum extrusion CNC machine:

- Machine Size and Capacity: Larger machines capable of handling bigger profiles naturally cost more due to increased material and engineering requirements.

- Precision and Technology: Machines with advanced technology such as high-speed spindles or multi-axis capabilities will be more expensive but offer greater flexibility in production.

- Brand Reputation: Established brands may charge a premium for their machines due to their reliability and service support.

- Customization: Custom-built machines tailored to specific production needs will generally incur higher costs than standard models.

- Additional Features: Features such as automatic tool changers, integrated software systems, and enhanced safety measures can also add to the price.

Key Features of Aluminum Extrusion CNC Machines

When considering an aluminum extrusion CNC machine, it's essential to evaluate its features:

- Cutting Area: The size of the cutting area determines the maximum size of aluminum profiles that can be processed. A larger cutting area allows for greater versatility in production runs.

- Tooling Options: Different tooling options allow for various machining operations like drilling, milling, or tapping. The ability to switch tools quickly can significantly enhance productivity.

- Control Systems: Advanced control systems can improve ease of use and precision in operations. User-friendly interfaces enable operators to program complex tasks with minimal training.

- Material Handling Systems: Integrated systems for loading and unloading materials can enhance productivity by reducing manual handling. Automated systems help minimize downtime between production runs.

Applications of Aluminum Extrusion CNC Machines

Aluminum extrusion CNC machines are used in various industries due to their versatility:

- Construction: For window frames, door frames, and structural components. The lightweight nature of aluminum makes it an attractive option for modern construction projects.

- Automotive: In manufacturing lightweight components that enhance fuel efficiency. The automotive industry increasingly relies on aluminum parts to meet regulatory standards for emissions.

- Aerospace: For creating parts that require high strength-to-weight ratios. Aerospace applications demand materials that provide both strength and reduced weight for improved performance.

- Electronics: In producing heat sinks and enclosures for electronic devices. Aluminum's thermal conductivity makes it ideal for dissipating heat in electronic applications.

Cost Comparison with Other Manufacturing Processes

When comparing aluminum extrusion CNC machining costs with other manufacturing methods like injection molding or stamping, it's important to consider:

| Manufacturing Process | Average Cost Range | Key Advantages |

| Aluminum Extrusion | $10,000 - $500,000+ | High strength-to-weight ratio; customization options |

| Injection Molding | $5,000 - $100,000+ | High volume production; complex shapes |

| Stamping | $15,000 - $300,000+ | Fast production; low per-unit cost |

Aluminum extrusion offers unique advantages such as customization capabilities and superior material properties that make it a preferred choice in many applications despite potentially higher initial costs compared to other methods.

Maintenance Considerations

Maintaining an aluminum extrusion CNC machine is crucial for ensuring longevity and optimal performance. Regular maintenance routines should include:

- Lubrication: Keeping moving parts well-lubricated reduces wear and tear over time.

- Calibration: Regular calibration ensures that the machine operates within specified tolerances.

- Software Updates: Keeping control software up-to-date can improve functionality and security.

- Inspection: Routine inspections help identify potential issues before they become significant problems.

Investing in a comprehensive maintenance plan can significantly reduce downtime and extend the life of the machine.

Future Trends in Aluminum Extrusion Technology

As technology continues to advance, several trends are emerging in the field of aluminum extrusion CNC machining:

- Increased Automation: The integration of robotics in material handling processes is becoming more common. This trend enhances efficiency by minimizing human intervention in repetitive tasks.

- Smart Manufacturing: The adoption of IoT (Internet of Things) technologies allows manufacturers to monitor machine performance remotely. Real-time data collection helps optimize operations and predict maintenance needs.

- Sustainability Practices: With growing environmental concerns, manufacturers are focusing on sustainable practices such as recycling scrap aluminum from production processes. This not only reduces waste but also lowers material costs.

Conclusion

The average cost of an aluminum extrusion CNC machine varies widely based on several factors including size, technology, brand reputation, and specific features. While entry-level machines may start around $10,000, high-end models can exceed $500,000. Understanding these costs is vital for manufacturers looking to invest in efficient production capabilities.

As industries continue to evolve towards lightweight materials and efficient manufacturing processes, investing in an aluminum extrusion CNC machine can provide significant long-term benefits. With its versatility across various applications—from construction to aerospace—aluminum extrusion remains a critical component in modern manufacturing strategies.

FAQ

1. What is the lifespan of an aluminum extrusion CNC machine?

The lifespan can vary but typically ranges from 10 to 20 years with proper maintenance.

2. How much does maintenance cost for these machines?

Annual maintenance costs can range from $1,500 to $5,000 depending on usage and complexity.

3. Can I finance an aluminum extrusion CNC machine?

Yes, many suppliers offer financing options tailored to business needs.

4. What materials can be processed besides aluminum?

Many machines can also process other non-ferrous metals like magnesium or copper alloys.

5. Is training available for operating these machines?

Most manufacturers provide training programs as part of the purchase agreement to ensure proper operation and safety compliance.