Content Menu

● Understanding Aluminum Extrusion Costs

● Current Pricing Trends in 2024

● The Aluminum Extrusion Process

● Visualizing Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What factors influence the cost of aluminum extrusion?

>> 2. How much does aluminum extrusion typically cost per pound?

>> 3. Why do larger orders reduce costs?

>> 4. What are common surface treatments for extruded aluminum?

>> 5. How does market volatility affect aluminum prices?

Aluminum extrusion is a widely used manufacturing process that shapes aluminum into desired forms by forcing it through a die. This method is popular across various industries, including construction, automotive, and consumer goods, due to its versatility and efficiency. As we move into 2024, understanding the average aluminum extrusion cost per pound is essential for businesses considering this manufacturing technique. This article will explore the factors influencing aluminum extrusion costs, provide insights into current pricing trends, and offer a comprehensive overview of the aluminum extrusion process.

Understanding Aluminum Extrusion Costs

The cost of aluminum extrusion can vary significantly based on several factors. Here are the primary elements that influence the average aluminum extrusion cost per pound:

Material Costs

The most significant factor affecting aluminum extrusion costs is the price of raw aluminum. The fluctuations in the global aluminum market directly impact production costs. As of early 2024, prices have seen notable increases due to various market dynamics, including supply chain disruptions and geopolitical tensions affecting aluminum exports.

Design Complexity

The complexity of the design also plays a crucial role in determining costs. More intricate designs require specialized tooling and advanced manufacturing technologies, which can increase both material and labor costs. Simple profiles typically cost less than custom extrusions that require unique dies and additional processing.

Quantity Ordered

Economies of scale significantly affect pricing. Larger orders generally result in lower per-unit costs due to reduced setup times and more efficient production runs. Conversely, smaller orders often incur higher costs per pound due to these inefficiencies.

Surface Treatment

Secondary processes such as anodizing, powder coating, or machining can add substantial costs to the final product. While these treatments enhance the appearance and durability of extruded aluminum, they also contribute to the overall expense.

Lead Time

Urgent orders requiring quick turnaround times may incur additional charges. Businesses should consider their lead time needs when budgeting for aluminum extrusion projects.

Current Pricing Trends in 2024

As of 2024, the average cost for aluminum extrusion ranges between $3 to $8 per pound in North America, depending on various factors such as complexity and quantity ordered. The price for common profiles tends to be on the lower end of this spectrum ($3 to $5 per pound), while custom profiles can reach up to $8 per pound or more.

Recent reports indicate that prices have increased by approximately $0.13 per pound as of May 2024 due to rising costs in both the London Metal Exchange (LME) and Midwest pricing trends. This increase reflects ongoing volatility in the raw material market influenced by global economic conditions.

The Aluminum Extrusion Process

Understanding how aluminum is extruded can provide further insight into why costs fluctuate. The process involves several key steps:

1. Preparation of the Die: The extrusion die is preheated to ensure optimal metal flow.

2. Heating the Aluminum Billet: An aluminum billet is heated until it becomes malleable enough for extrusion without melting.

3. Extrusion: A powerful ram pushes the heated billet through the die, forming it into a specific profile.

4. Cooling: The extruded material is cooled using air or water to solidify its shape.

5. Cutting: Once cooled, extrusions are cut to specified lengths.

6. Finishing: Additional processes such as machining or surface treatments may be applied.

This detailed process requires specialized equipment and skilled labor, contributing to overall production costs.

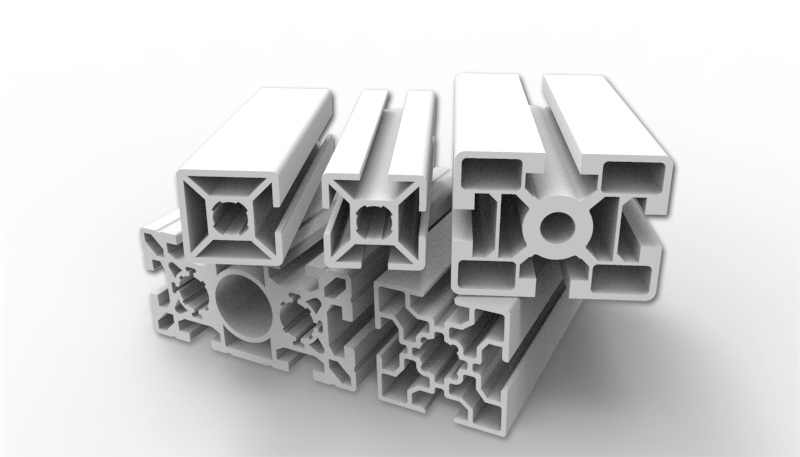

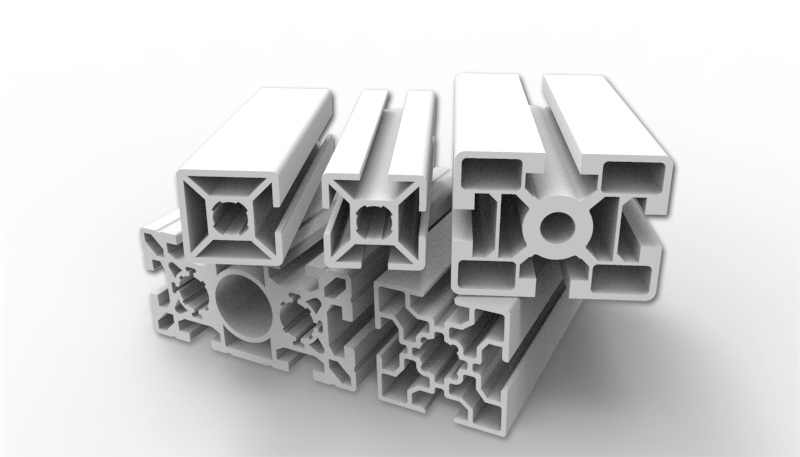

Visualizing Aluminum Extrusion

To better understand this process and its associated costs, consider viewing videos or images that depict each stage of aluminum extrusion:

- [Aluminum Extrusion Process Video](https://www.youtube.com/watch?v=iiGlq7408ME): This video provides an in-depth look at how aluminum is extruded, showcasing each step from die preparation to finishing.

- Images of Aluminum Extrusions: Various stock images illustrate different profiles and applications of extruded aluminum in real-world scenarios.

Conclusion

In summary, the average aluminum extrusion cost per pound in 2024 ranges from $3 to $8 depending on several factors including material prices, design complexity, order quantity, surface treatments, and lead times. As prices continue to fluctuate due to global market conditions, businesses must stay informed about these trends when planning their projects involving aluminum extrusions.

Understanding these dynamics will help manufacturers make informed decisions about their production processes and budget accordingly for their needs.

Frequently Asked Questions

1. What factors influence the cost of aluminum extrusion?

The cost of aluminum extrusion is influenced by material prices, design complexity, order quantity, surface treatments, and lead times.

2. How much does aluminum extrusion typically cost per pound?

In 2024, the average cost ranges from $3 to $8 per pound depending on various factors such as design complexity and quantity ordered.

3. Why do larger orders reduce costs?

Larger orders benefit from economies of scale which reduce setup times and increase production efficiency, leading to lower per-unit prices.

4. What are common surface treatments for extruded aluminum?

Common surface treatments include anodizing and powder coating which enhance durability and appearance but add to overall costs.

5. How does market volatility affect aluminum prices?

Market volatility can lead to fluctuations in raw material prices due to supply chain disruptions or geopolitical tensions impacting production and distribution channels.