Content Menu

● The Aluminum Extrusion Process

● Benefits of Aluminum Extrusion

● Applications of Aluminum Extrusion

● Techniques in Aluminum Extrusion

● Custom Aluminum Extrusions

● Challenges in Aluminum Extrusion

● Future of Aluminum Extrusion

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. How is aluminum extrusion different from other manufacturing processes?

>> 3. What are the main advantages of using aluminum extrusions?

>> 4. Can aluminum extrusions be customized?

>> 5. What industries benefit from aluminum extrusion?

The Aluminum Extrusion Process

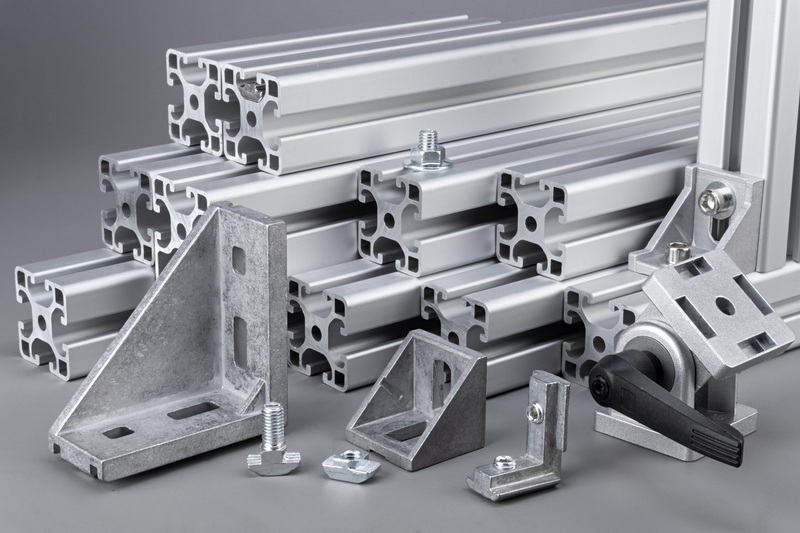

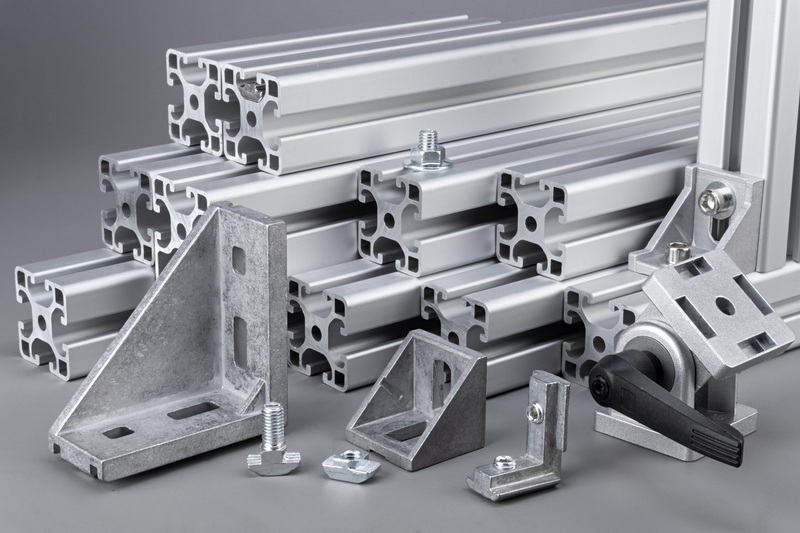

The aluminum extrusion process begins with heating an aluminum billet, which is a solid block of aluminum, to a temperature that makes it malleable. Once heated, the billet is placed in an extrusion press, where it is forced through a die. The die determines the final shape of the extruded aluminum.

Key steps in the aluminum extrusion process include:

- Heating the Billet: The aluminum is heated to a specific temperature to enhance its plasticity.

- Extrusion: The heated billet is pushed through the die using a hydraulic press.

- Cooling: After exiting the die, the extruded aluminum is cooled, often using air or water.

- Cutting: The continuous length of extruded aluminum is cut into desired lengths.

There are various types of aluminum alloys used in the extrusion process, each offering different properties and benefits. Common alloys include 6061 and 6063, known for their excellent corrosion resistance and strength.

Benefits of Aluminum Extrusion

Aluminum extrusion offers numerous advantages, making it a popular choice in manufacturing:

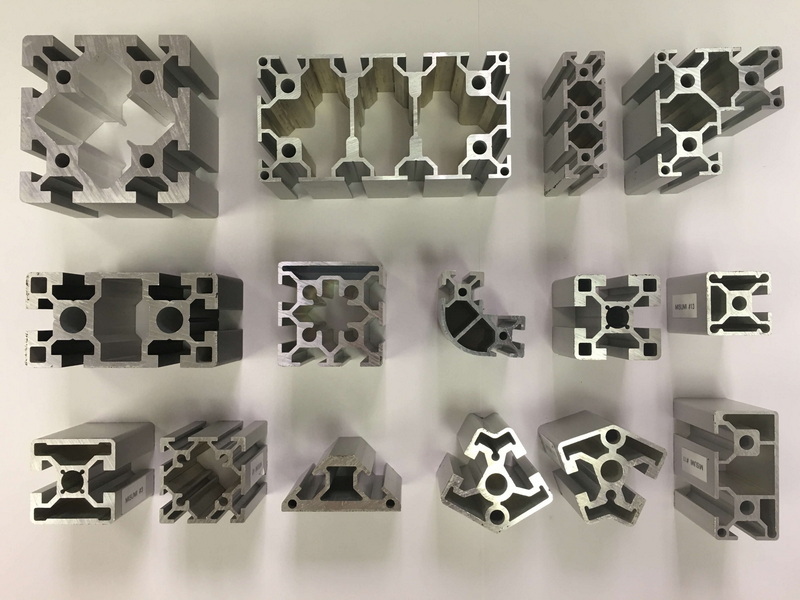

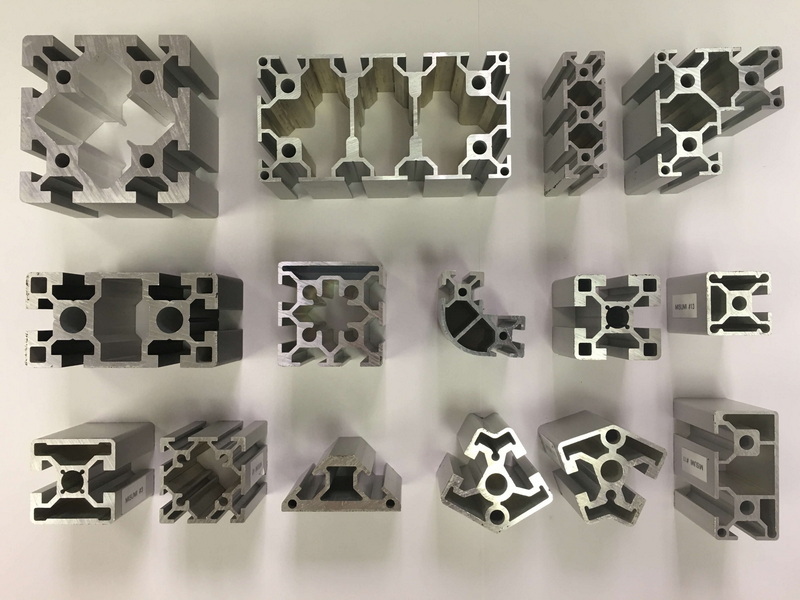

- Design Flexibility: The process allows for the creation of complex shapes, including hollow and semi-hollow profiles, which can be tailored to specific applications.

- Cost-Effectiveness: Extrusion is often more economical than other manufacturing methods, especially for large production runs.

- Lightweight and Strength: Aluminum is known for its high strength-to-weight ratio, making extruded products both lightweight and durable.

Applications of Aluminum Extrusion

Aluminum extrusions are used in a wide range of applications across various industries:

- Construction: Used in window frames, door frames, and structural components.

- Automotive: Employed in vehicle frames, heat exchangers, and other components.

- Electronics: Utilized in heat sinks, enclosures, and structural supports.

Examples of products made from aluminum extrusion include:

- Railings and Fencing: Lightweight yet strong, ideal for outdoor applications.

- Heat Sinks: Efficiently dissipate heat in electronic devices.

- Furniture: Modern designs often incorporate aluminum extrusions for aesthetic and functional purposes.

Techniques in Aluminum Extrusion

There are several techniques used in aluminum extrusion, each suited for different applications:

- Hot Extrusion: The aluminum is heated above its recrystallization temperature, allowing for easier shaping and complex profiles.

- Cold Extrusion: Performed at room temperature, this method is used for producing smaller, more precise components.

- Direct vs. Indirect Extrusion: In direct extrusion, the billet is pushed through the die, while in indirect extrusion, the die moves towards the billet.

Custom Aluminum Extrusions

Customization is a significant aspect of aluminum extrusion. Manufacturers can create unique profiles tailored to specific needs, enhancing functionality and aesthetics. Custom extrusions are often used in specialized applications, such as:

- Architectural Features: Custom shapes for building facades and interior designs.

- Industrial Equipment: Tailored components for machinery and equipment.

Challenges in Aluminum Extrusion

While aluminum extrusion is a highly efficient process, it does come with challenges:

- Quality Control: Ensuring dimensional accuracy and surface finish can be difficult.

- Material Waste: Excess material cut off during the process can lead to waste if not recycled properly.

To address these challenges, manufacturers implement best practices, such as regular maintenance of extrusion equipment and careful monitoring of process parameters.

Future of Aluminum Extrusion

The aluminum extrusion industry is evolving, with innovations aimed at improving efficiency and sustainability. Key trends include:

- Advanced Manufacturing Techniques: The use of automation and robotics to enhance production efficiency.

- Sustainability: Increased focus on recycling and using recycled aluminum in the extrusion process, reducing environmental impact.

Conclusion

Aluminum extrusion is a vital manufacturing process that offers numerous benefits, including design flexibility, cost-effectiveness, and lightweight strength. Its applications span various industries, making it an essential component in modern manufacturing. As the industry continues to innovate, aluminum extrusion will play a crucial role in meeting the demands of future technologies and sustainable practices.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy by forcing it through a die to create specific cross-sectional profiles.

2. How is aluminum extrusion different from other manufacturing processes?

Unlike other methods, aluminum extrusion allows for the creation of complex shapes and profiles, making it highly versatile for various applications.

3. What are the main advantages of using aluminum extrusions?

The main advantages include design flexibility, cost-effectiveness, and a high strength-to-weight ratio.

4. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be tailored to meet specific design and functional requirements, making them suitable for a wide range of applications.

5. What industries benefit from aluminum extrusion?

Industries such as construction, automotive, and electronics extensively use aluminum extrusions for various products and components.