Content Menu

● Introduction to Krauss Maffei

● Overview of Extrusion Automatic Centering Technology

>> Key Features of Automatic Centering Technology

>> Applications of Automatic Centering Technology

>> Technical Specifications

● Benefits of Krauss Maffei's Extrusion Automatic Centering Technology

● Integration with Smart Manufacturing Technologies

>> SmartAssist and Digital Products

● Conclusion

● FAQs

>> 1. What are the primary benefits of using Krauss Maffei's extrusion automatic centering technology?

>> 2. How does the automatic centering technology achieve precise wall thickness and concentricity?

>> 3. What industries can benefit from Krauss Maffei's extrusion automatic centering technology?

>> 4. How does Krauss Maffei integrate smart manufacturing technologies with its extrusion systems?

>> 5. What is the significance of Krauss Maffei's long history in the plastics and rubber processing industry?

● Citations:

KraussMaffei, a renowned leader in plastics and rubber processing machinery, has developed cutting-edge extrusion technologies to enhance production efficiency and product quality. Among these innovations, the Krauss Maffei extrusion automatic centering technology stands out for its precision and cost-effectiveness in producing high-quality rubber and plastic products. This article delves into the details of this technology, its applications, and its benefits.

Introduction to Krauss Maffei

KraussMaffei has been at the forefront of plastics and rubber processing for over 180 years, offering a wide range of machinery and systems for injection molding, extrusion, and reaction process machinery[8][11]. Their commitment to innovation and customer satisfaction has made them a trusted partner across various industries, including automotive, packaging, medical, and construction[8].

Overview of Extrusion Automatic Centering Technology

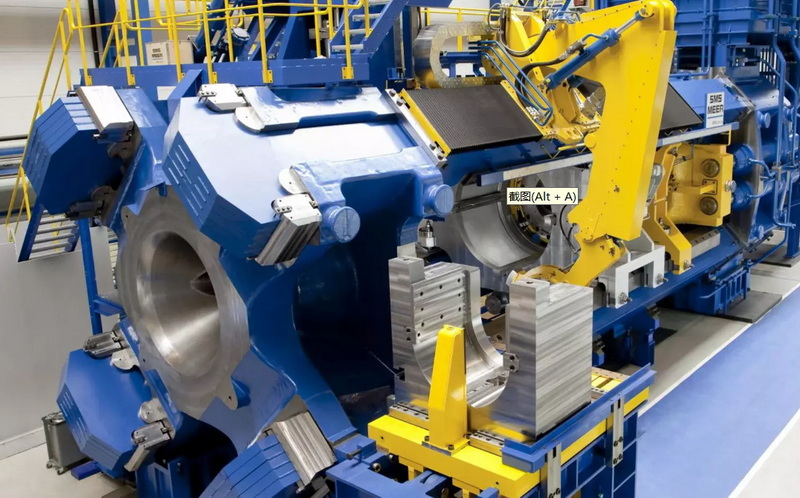

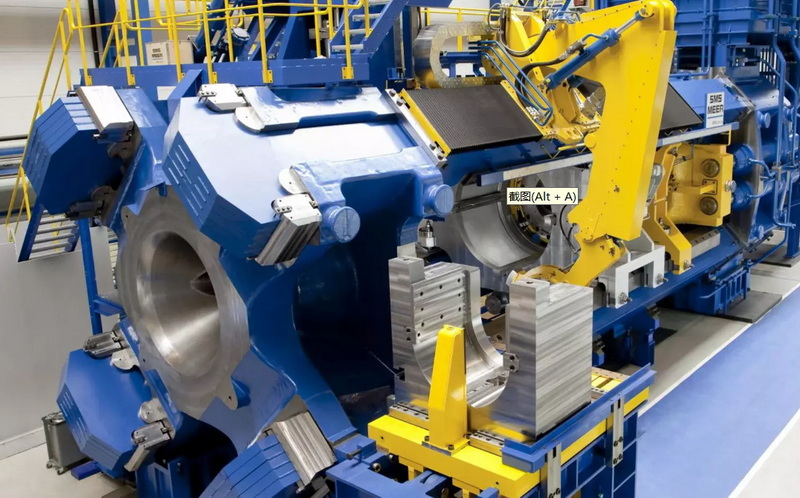

The Krauss Maffei extrusion automatic centering technology is designed to optimize the production of rubber tubes and hoses by ensuring precise wall thickness and concentricity. This is achieved through the use of self-centering tube dies equipped with a wall thickness gauge, which continuously monitor and adjust the extrusion process to maintain uniformity and reduce material waste[4].

Key Features of Automatic Centering Technology

1. Precision and Uniformity: The technology ensures that the wall thickness and concentricity of the tubes are maintained within tight tolerances, resulting in high-quality products with minimal variations[4].

2. Material Savings: By optimizing wall thickness, manufacturers can achieve significant material savings, which can lead to substantial cost reductions over time[4].

3. Efficiency and Speed: The system allows for rapid setup and adjustment, reducing downtime and increasing overall production efficiency[4].

4. Flexibility: The technology is adaptable to various production requirements, including different extrusion pressures and tube diameters[4].

Applications of Automatic Centering Technology

The Krauss Maffei extrusion automatic centering technology is versatile and can be applied in multiple industries:

- Automotive Industry: For producing high-quality hoses and tubes used in vehicles, ensuring reliability and performance[1][6].

- Medical Sector: For manufacturing precise medical tubing and hoses that require high sterility and uniformity[1].

- Construction Industry: For creating durable and consistent rubber components used in construction materials[1].

Technical Specifications

The technology includes features such as:

- Straight-through and Crosshead Dies: These dies are designed for high-quality hose production, offering options for manual or hydraulic operation for easy cleaning and tool replacement[1].

- X-ray Measuring System: This system continuously monitors and adjusts the wall thickness and eccentricity of the rubber profiles, ensuring precise control over the extrusion process[1].

- Automatic Correction: Any deviations in wall thickness or concentricity are automatically corrected, ensuring consistent product quality[4].

Benefits of Krauss Maffei's Extrusion Automatic Centering Technology

The implementation of Krauss Maffei extrusion automatic centering technology offers several benefits to manufacturers:

1. Improved Product Quality: The technology ensures that products meet high standards of uniformity and precision, enhancing customer satisfaction and brand reputation[4].

2. Cost Savings: By reducing material waste and minimizing production downtime, manufacturers can achieve significant cost savings[4].

3. Increased Efficiency: The automated process allows for faster setup and adjustment times, increasing overall production efficiency[4].

4. Competitive Advantage: Companies that adopt this technology can differentiate themselves through superior product quality and efficiency, gaining a competitive edge in the market[4].

Integration with Smart Manufacturing Technologies

KraussMaffei also integrates its extrusion technologies with smart manufacturing solutions, including process monitoring, energy optimization, and augmented reality tools[3]. These digital products enhance operational efficiency, reduce energy consumption, and provide real-time insights into production processes.

SmartAssist and Digital Products

KraussMaffei's smartAssist platform offers global service support, enabling remote communication with experts for troubleshooting and maintenance[5]. Additionally, their digital products include advanced monitoring systems and energy optimization tools, which help manufacturers optimize their production processes[3].

Conclusion

Krauss Maffei's extrusion automatic centering technology represents a significant advancement in the production of rubber and plastic tubes. By ensuring precise wall thickness and concentricity, this technology enhances product quality, reduces material waste, and increases production efficiency. As manufacturers continue to seek innovative solutions to improve their operations, technologies like those offered by KraussMaffei will play a crucial role in shaping the future of the plastics and rubber processing industries.

FAQs

1. What are the primary benefits of using Krauss Maffei's extrusion automatic centering technology?

The primary benefits include improved product quality, cost savings through reduced material waste, and increased production efficiency.

2. How does the automatic centering technology achieve precise wall thickness and concentricity?

The technology uses self-centering tube dies equipped with a wall thickness gauge to continuously monitor and adjust the extrusion process.

3. What industries can benefit from Krauss Maffei's extrusion automatic centering technology?

Industries such as automotive, medical, and construction can benefit from this technology due to its ability to produce high-quality rubber components.

4. How does Krauss Maffei integrate smart manufacturing technologies with its extrusion systems?

KraussMaffei integrates smart manufacturing technologies through platforms like smartAssist, which offers real-time monitoring and energy optimization tools.

5. What is the significance of Krauss Maffei's long history in the plastics and rubber processing industry?

KraussMaffei's long history signifies its commitment to innovation and customer satisfaction, making it a trusted partner across various industries.

Citations:

[1] https://bruys.nl/sites/default/files/assets/files/downloads/ext-br-hoseextrusion-en.pdf

[2] https://www.kraussmaffei.com/media/datastore/cms/media/ext/downloads/ext-br-rohrextrusionsanlagen-en.pdf

[3] https://www.plasticsmachinerymanufacturing.com/injection-molding/article/55020256/kraussmaffei-highlights-smart-manufacturing-technologies

[4] https://press.kraussmaffei.com/en/news/continuous-tube-die-centering-for-precise-wall-thickness-with-maximum-material-savings

[5] https://www.kraussmaffei.com/en/our-products/digital-products/smartassist

[6] https://www.linkedin.com/company/krauss-maffei

[7] https://www.plasticsmachinerymanufacturing.com/injection-molding/article/53073606/kraussmaffei-corp-kraussmaffei-looks-for-opportunities-to-grow

[8] https://www.tiretechnologyinternational.com/supplier-spotlight/kraussmaffei

[9] https://www.smart-hmi.com/case-study/krauss-maffei

[10] https://www.plasticsmachinerymanufacturing.com/injection-molding/article/21215738/krauss-maffei-upgrading-innovation-centers-capabilities

[11] https://www.shawnee.edu/areas-study/college-professional-studies/engineering-technologies/bachelor-degrees/plastics/partners/krauss-maffei

[12] https://www.k-online.com/en/k-mag/machinery-plants/krauss-maffei-laboratory-extruder-bluepower

[13] https://www.kraussmaffei.com/en/our-products/extrusion-heads

[14] https://www.kraussmaffeichina.com/media/download/cms/media/chinawebsite/rpm/km-br-mixingheads-en.pdf

[15] http://www.polyregion.org/files/attachments/13135/449573_03_Traniello_Extrusion_profiles_and_plates_Krauss_Maffei_.pdf

[16] https://www.kraussmaffei.com/en/our-technologies/extrusion-technology

[17] https://www.kraussmaffei.com

[18] https://www.plastikmedia.co.uk/kraussmaffei-debuts-self-centering-tube-dies/

[19] https://www.plasticsnews.com/sponsored-content/focus-efficiency-new-kraussmaffei-extrusion-plant

[20] https://www.plasticsnews.com/krauss-maffei-sponsored-content