Content Menu

● Blown Film Extrusion

>> The Basic Process

>> Components of Blown Film Extrusion Equipment

>> Applications of Blown Film Extrusion

● Cast Film Extrusion

>> The Basic Process

>> Components of Cast Film Extrusion Equipment

>> Applications of Cast Film Extrusion

● Key Differences Between Blown Film and Cast Film Extrusion

● Advantages of Film Extrusion Equipment

● Conclusion

● FAQ

>> 1. What types of films can be produced using film extrusion equipment?

>> 2. How is the thickness of the film controlled in the blown film extrusion process?

>> 3. What are the primary raw materials used in blown film machines?

>> 4. What is the role of the extruder in the film extrusion process?

>> 5. What are the advantages of cast film extrusion over blown film extrusion?

● Citations:

Film extrusion equipment is essential for manufacturing plastic films used in various industries, including packaging, agriculture, and construction[10][5]. The process involves melting plastic pellets and shaping them into a continuous film[2]. The two primary methods are blown film extrusion and cast film extrusion[6].

Blown Film Extrusion

Blown film extrusion is a common method for producing plastic films. It involves extruding a tube of molten plastic and inflating it with air to create a bubble[2][3]. This bubble is then cooled and collapsed into a thin film[3].

The Basic Process

1. Preparing the Material: Plastic pellets are fed into an extruder, where they are heated and melted to create a homogeneous mass of molten plastic[3][2].

2. Extrusion: The molten plastic is pumped through a circular die, and air is blown into the center of the die, causing the plastic to expand into a bubble or tube[3][2].

3. Cooling: The bubble is cooled by air or cooling rollers to solidify the plastic[3]. As the film cools, it crystallizes at the frost line[1].

4. Collapsing: The tube is collapsed through rollers into a flat film[3][2].

5. Winding: The film is wound onto rolls for further processing or use[3][2].

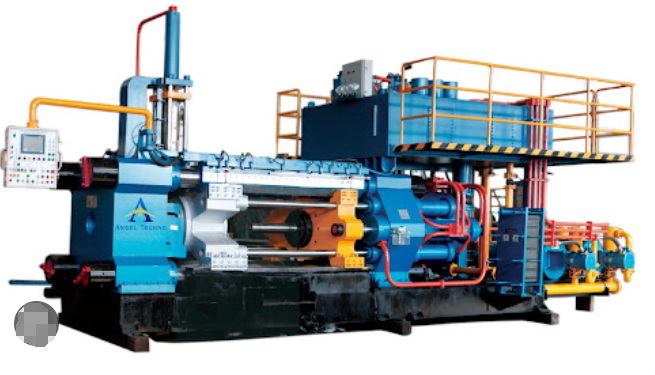

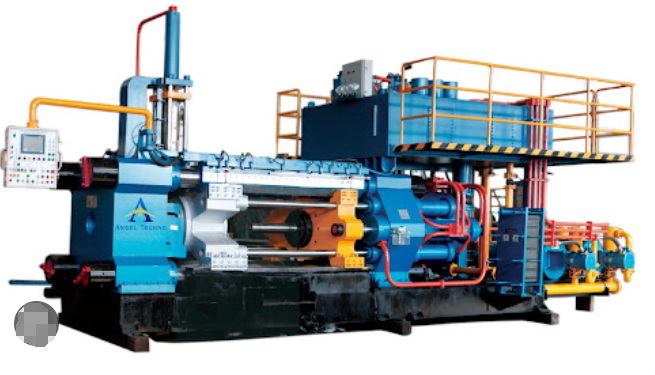

Components of Blown Film Extrusion Equipment

- Extruder: Melts and mixes the plastic pellets[10][8]. It consists of a heated barrel and a rotating screw[1].

- Die Head: Shapes the molten plastic into a tube and introduces air to form the bubble[8].

- Air Ring: Cools the bubble as it moves upwards[5].

- Nip Rollers: Flatten the bubble into a film[1].

- Winder: Collects the finished film onto rolls[2].

Applications of Blown Film Extrusion

Blown film extrusion is used to produce films with different properties for various applications[8]:

- Packaging Films: For food packaging, industrial packaging[11].

- Agricultural Films: For greenhouse covers and mulch films.

- Construction Films: For vapor barriers and protective films.

- Bags: Production of plastic bags[5].

Cast Film Extrusion

Cast film extrusion involves extruding plastic through a flat die onto a cooled roller, which solidifies the film[6]. This method is known for producing high-clarity films with uniform thickness[6].

The Basic Process

1. Material Preparation: Plastic resins are fed into an extruder, where they are melted and mixed into a consistent mixture[6].

2. Extrusion: The molten material is extruded through a flat die onto a cold roller[6].

3. Cooling: The film is cooled and solidified by the cold roller, often with additional air or vacuum cooling[6].

4. Trimming and Winding: The edges of the film are trimmed, and the film is wound onto a roll[6].

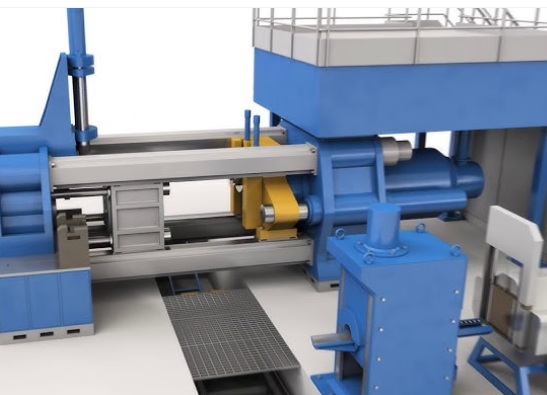

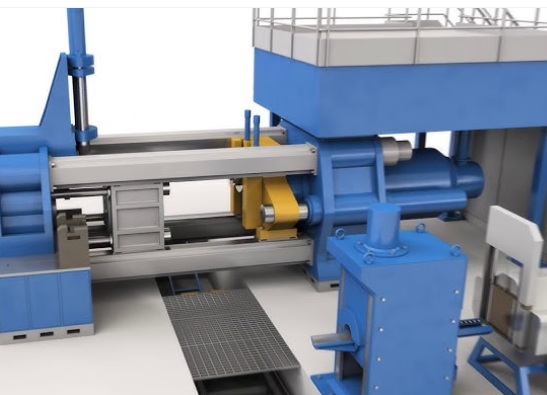

Components of Cast Film Extrusion Equipment

- Extruder: Melts and mixes the plastic resins[6].

- Flat Die System: Flattens the molten plastic into a thin film[6].

- Cooling Unit: Solidifies the film using a primary roll, a secondary roll, a motorized roll, a vacuum box, and an air knife[6].

- Automatic Gauge Control System: Measures and controls film thickness[6].

- Winder: Transforms the extruded film into rolls[6].

Applications of Cast Film Extrusion

Cast film extrusion is suitable for applications requiring high clarity and uniform thickness[6]:

- Food Packaging: For flexible packaging that requires a clear view of the product.

- Lamination Films: For creating multi-layer packaging materials.

- Labels: For producing clear labels with high-quality printing.

- Medical Packaging: Where clarity and material integrity are critical.

Key Differences Between Blown Film and Cast Film Extrusion

| Feature | Blown Film Extrusion | Cast Film Extrusion |

| Film Formation | Molten plastic is blown into a bubble and then collapsed into a film23. | Molten plastic is extruded through a flat die onto a cooled roller6. |

| Film Properties | Can produce films with varying thicknesses and good strength8. | Produces films with high clarity and uniform thickness6. |

| Applications | Packaging films, agricultural films, construction films, and bags85. | Food packaging, lamination films, labels, and medical packaging6. |

| Cooling Method | Air cooling or cooling rollers3. | Cooled roller with additional air or vacuum cooling6. |

| Equipment | Extruder, die head, air ring, nip rollers, and winder1085. | Extruder, flat die system, cooling unit, automatic gauge control system, and winder6. |

Advantages of Film Extrusion Equipment

- Versatility: Can produce a wide range of film types and thicknesses[9].

- Efficiency: High-speed production capabilities[6].

- Customization: Ability to add additives for specific properties, such as UV stabilizers and anti-statics[10].

- Cost-Effectiveness: Economical for large-scale production[11].

Conclusion

Film extrusion equipment is a critical component in the manufacturing of plastic films. Both blown film and cast film extrusion processes offer distinct advantages and are chosen based on the desired film properties and applications. Understanding the equipment and processes involved is essential for producing high-quality plastic films efficiently and cost-effectively.

FAQ

1. What types of films can be produced using film extrusion equipment?

Film extrusion equipment can produce a wide range of films, including HDPE, LDPE, LLDPE, recycled pellets, biodegradable films, and films with CaCO3[9].

2. How is the thickness of the film controlled in the blown film extrusion process?

The thickness of the film is controlled by adjusting the speed of the extruder, the airflow into the bubble, and the size of the die[2].

3. What are the primary raw materials used in blown film machines?

Common raw materials include PE, PP, PVC, EVA, PA, and PS. Additives may be included to enhance properties[11].

4. What is the role of the extruder in the film extrusion process?

The extruder melts plastic materials and mixes the resulting molten polymer to obtain a homogeneous mixture. It moves the material with a spinning screw along a heated barrel[6].

5. What are the advantages of cast film extrusion over blown film extrusion?

Cast film extrusion offers improved efficiency and sustainability standards and is known for producing films with high clarity and uniform thickness[6].

Citations:

[1] https://amcorplastics.com/blown-film-extrusion-process-explained/

[2] https://www.plastar-machine.com/en/article/the-manufacturing-process-of-blown-film-extrusion.html

[3] https://eupegypt.com/blog/blown-film-extrusion/

[4] https://create.vista.com/photos/extruder-machine/

[5] https://www.youtube.com/watch?v=-0fgnyW9xpM

[6] https://europlas.com.vn/en-US/blog-1/cast-film-extrusion-process-the-ultimate-guide

[7] https://www.won-plus.com/blog/extrusion-technology-related-questions-and-answers_b40

[8] https://www.prm-taiwan.com/blog/guide-to-blown-film-extrusion-machines_412

[9] https://www.polystarco.com/blog-detail/frequently-asked-questions-about-blown-film-machines/

[10] https://www.chyiyang.com/guide-to-blown-film-extrusion-machines

[11] https://www.plastar-machine.com/en/news/faq.html

[12] https://www.bpf.co.uk/plastipedia/processes/film-extrusion.aspx

[13] https://www.spg-pack.com/en/blog/what-is-plastic-film-extrusion/

[14] https://www.jwellmachine.com/mechanical-principle-of-extruder%EF%BF%BC/

[15] https://www.twi-global.com/technical-knowledge/faqs/plastic-extrusion

[16] https://leverwood.com/how-does-a-plastic-extrusion-machine-work/

[17] https://plasticextrusiontech.net/machines-used-in-the-plastic-extrusion-process/

[18] https://www.pearltechinc.com/2025/02/13/extrusion-equipment-blown-film-efficiency/

[19] https://dallasplastics.com/blog/blown-film-extrusion-manufacturing-process/

[20] https://en.wikipedia.org/wiki/Plastic_extrusion

[21] https://www.shutterstock.com/video/search/blown-film-extrusion

[22] https://www.shutterstock.com/search/film-extrusion

[23] https://stock.adobe.com/search?k=extrusion

[24] https://www.istockphoto.com/photos/film-extrusion-photos

[25] https://www.youtube.com/watch?v=Rky0Bjem0vg

[26] https://www.shutterstock.com/search/blown-film-machine

[27] https://www.youtube.com/playlist?list=PL8B1r8zT-52HCmUpwK-lBlZOkRJO2LzIo

[28] https://www.istockphoto.com/photos/extrusion

[29] https://www.youtube.com/watch?v=YSTp0JBobLY

[30] https://stock.adobe.com/search?k=plastic+extrusion+machine