Content Menu

● Understanding Extrusion

● Responsibilities of an Extrusion Equipment Operator

● Skills Required for Extrusion Operators

● Career Pathways

>> Job Outlook

● Conclusion

● FAQ

>> 1. What does an extrusion operator do?

>> 2. What industries employ extrusion operators?

>> 3. What skills are necessary for an extrusion operator?

>> 4. Is formal education required to become an extrusion operator?

>> 5. What is the job outlook for extrusion operators?

● Citations:

An "extrusion equipment operator" plays a vital role in the manufacturing process, particularly in industries that require the shaping of materials such as plastics, metals, and even food products. This article will explore the responsibilities, skills, and career prospects of extrusion operators, as well as provide insights into the machinery they operate.

Understanding Extrusion

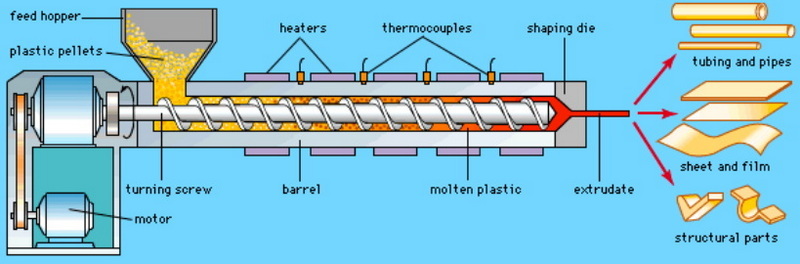

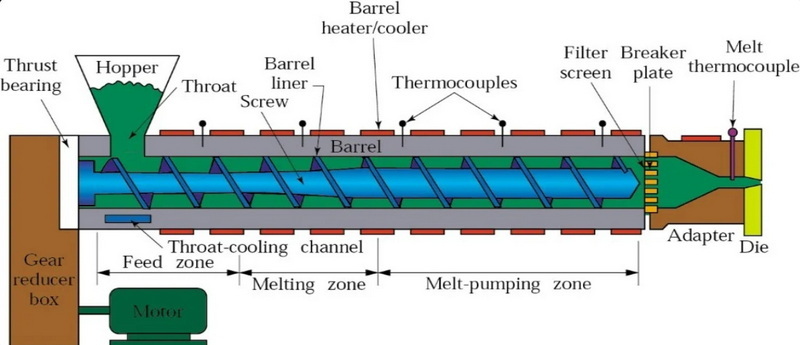

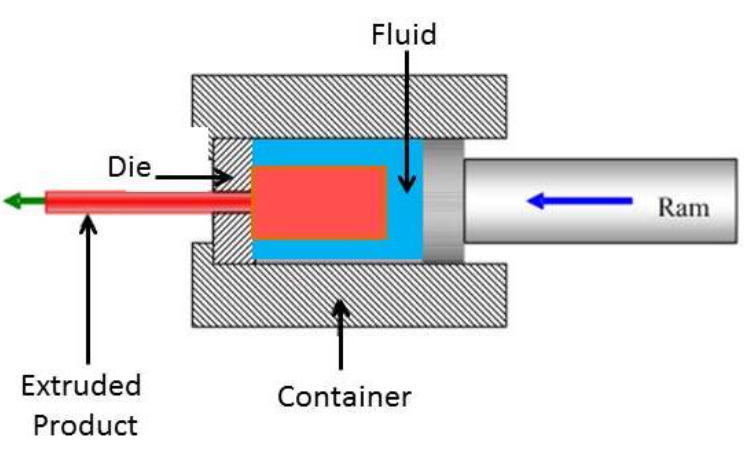

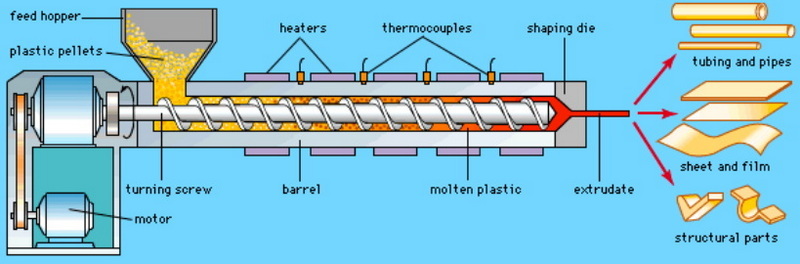

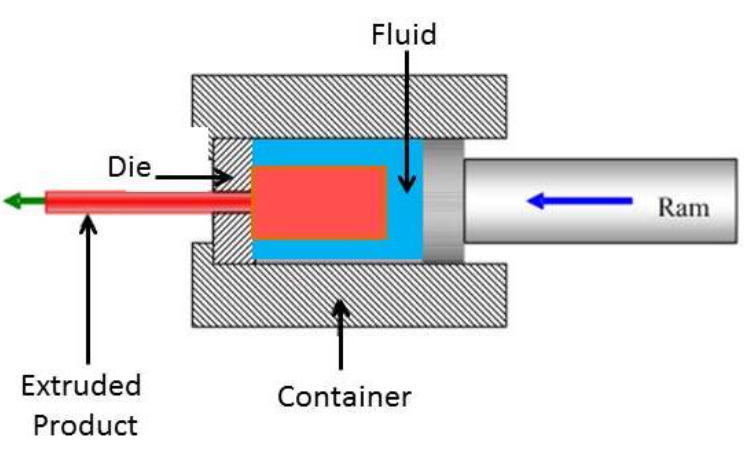

Extrusion is a process used to create objects of a fixed cross-sectional profile. The material is pushed through a die, which shapes it into the desired form. The extrusion process is widely used in various sectors, including:

- Plastics Manufacturing: Creating items like pipes, sheets, and films.

- Metals Production: Forming aluminum and other metal profiles.

- Food Processing: Producing items such as pasta and snacks.

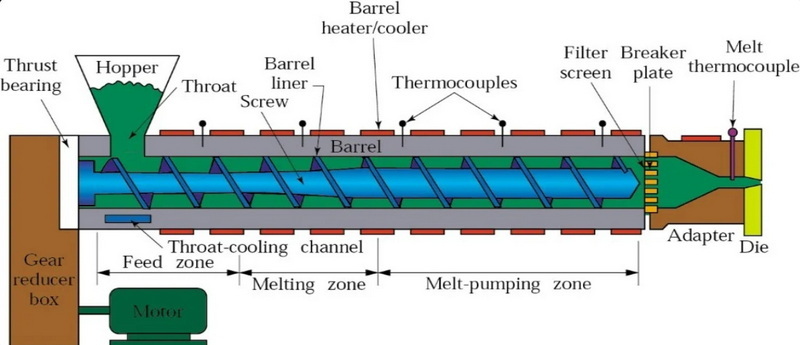

The machinery responsible for this process is known as an extruder, which can vary in complexity from simple manual machines to highly automated systems.

Responsibilities of an Extrusion Equipment Operator

Extrusion operators are tasked with several critical responsibilities that ensure the smooth operation of extrusion machines. These include:

- Machine Setup: Operators must set up the extrusion machines according to specific job requirements. This involves selecting and installing dies, configuring machine controls, and adjusting temperatures and pressures.

- Operation Monitoring: Continuous monitoring of the extrusion process is essential. Operators need to ensure that materials are being shaped correctly and to specification. This includes adjusting controls to maintain quality and consistency.

- Quality Control: Inspecting extruded products for defects is a crucial part of the role. Operators must be adept at detecting any deviations from specifications and making necessary adjustments to the machine settings.

- Routine Maintenance: Conducting regular maintenance tasks such as cleaning, lubricating, and performing minor repairs on the machinery helps prevent breakdowns and ensures longevity.

- Record Keeping: Maintaining accurate records of production data, machine settings, and maintenance activities is vital for tracking performance and compliance with safety regulations.

Skills Required for Extrusion Operators

To be successful in this role, extrusion operators need a combination of technical skills and personal attributes:

- Technical Proficiency: A strong understanding of mechanical and thermal dynamics related to the extrusion process is essential. Operators should also be capable of troubleshooting and maintaining machinery.

- Attention to Detail: Precision is critical in extrusion; operators must carefully monitor machine settings to ensure products meet exact specifications.

- Problem-Solving Skills: The ability to quickly diagnose and fix issues that arise during production is crucial for maintaining productivity.

- Physical Stamina and Strength: Operators often handle heavy materials and equipment, requiring physical endurance.

- Safety Consciousness: Adhering to safety protocols is vital to prevent accidents and injuries in the workplace.

Career Pathways

The pathway to becoming an extrusion operator typically involves on-the-job training rather than formal education. While some employers may hire candidates without a high school diploma or GED, many prefer candidates with at least a high school education. New hires usually start with basic tasks under the supervision of experienced operators before gradually taking on more complex responsibilities.

Job Outlook

According to the U.S. Bureau of Labor Statistics, jobs for extruding and drawing machine operators are expected to grow by about 8% from 2010 to 2020. This growth is attributed largely to retirements within the industry rather than new job creation due to automation and competition from overseas manufacturers.

Conclusion

Extrusion equipment operators are essential in various manufacturing sectors, ensuring that machines operate smoothly while producing high-quality products. Their role requires a blend of technical skills, attention to detail, and a commitment to safety. As industries continue to evolve with technology, the demand for skilled operators who can adapt will remain significant.

FAQ

1. What does an extrusion operator do?

An extrusion operator sets up and controls machines that shape materials by forcing them through a die. They monitor production processes, perform quality checks, and conduct routine maintenance on machinery.

2. What industries employ extrusion operators?

Extrusion operators are employed in various industries including plastics manufacturing, aerospace manufacturing, automotive parts production, food processing, and metal fabrication.

3. What skills are necessary for an extrusion operator?

Key skills include technical proficiency in operating machinery, attention to detail for quality control, problem-solving abilities for troubleshooting issues, physical stamina for handling materials, and adherence to safety protocols.

4. Is formal education required to become an extrusion operator?

While some employers may prefer candidates with a high school diploma or GED, many positions offer on-the-job training without formal educational requirements.

5. What is the job outlook for extrusion operators?

The job outlook for extruding and drawing machine operators is positive with an expected growth rate of about 8% over the next decade due primarily to retirements within the industry.

Citations:

[1] https://www.indeed.com/career-advice/finding-a-job/what-does-extrusion-operator-do

[2] https://www.zippia.com/extrusion-operator-jobs/what-does-an-extrusion-operator-do/

[3] https://www.salary.com/research/job-description/benchmark/extrusion-operator-job-description

[4] https://www.youtube.com/watch?v=WaB-dsB1Kfk

[5] https://www.youtube.com/watch?v=KcyQTON2tho

[6] https://www.alamy.com/stock-photo/extrusion-machine.html

[7] https://www.rssinc.com/blog/what-is-an-extrusion-machine-operator/

[8] https://www.rssinc.com/blog/understanding-the-role-of-an-extrusion-operator/

[9] https://business.muskego.org/jobs/info/manufacturing-machine-operator-extrusion-3rd-shift-2562

[10] https://paulmurphyplastics.com/industry-news-blog/what-is-a-plastic-extrusion-operator-2/