Content Menu

● Understanding the Extrusion Process

● Applications of Extrusion Bars

● Benefits of Extrusion Bar Production

● Why Is Extrusion Bar Production Important for Manufacturing?

● Emerging Trends in Aluminum Extrusion

● Challenges in Aluminum Extrusion

● Conclusion

● FAQ

>> 1. What types of materials can be extruded?

>> 2. How does the extrusion process differ from casting?

>> 3. What industries benefit most from aluminum extrusion?

>> 4. Can custom shapes be created through extrusion?

>> 5. What finishing options are available for extruded products?

● Citations:

Extrusion bar production is a vital manufacturing process that shapes materials, particularly metals like aluminum, into desired cross-sectional profiles by forcing them through a die. This technique has gained immense importance across various industries due to its efficiency, versatility, and cost-effectiveness. In this article, we will explore the intricacies of extrusion bar production, its applications, benefits, and why it plays a crucial role in modern manufacturing.

Understanding the Extrusion Process

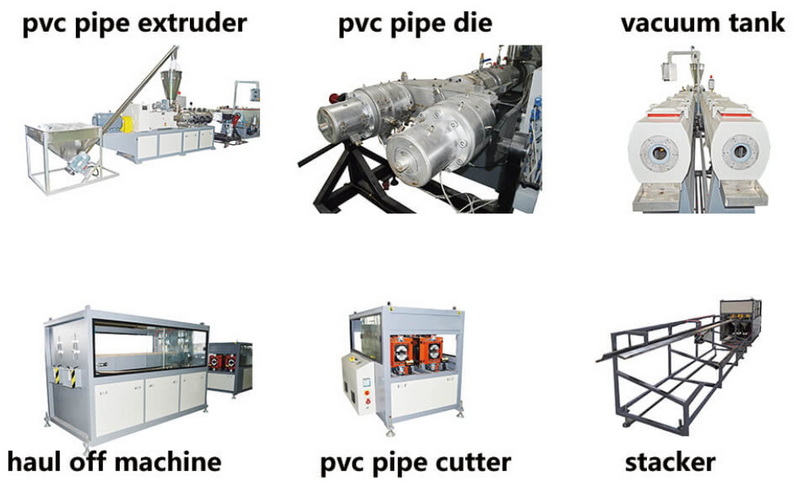

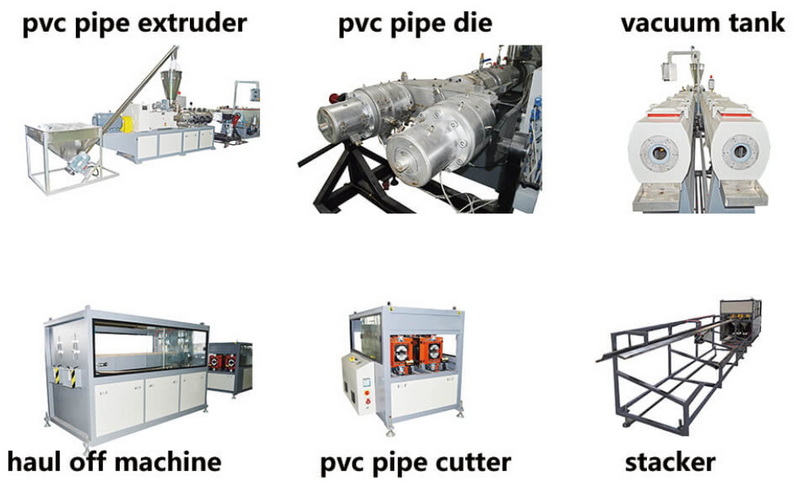

The extrusion process involves several key steps that transform raw materials into finished products. Below are the main phases of aluminum extrusion:

1. Billet Preparation: The process begins with the preparation of aluminum billets, which are solid cylindrical blocks of aluminum alloy. These billets are cut from larger logs and preheated to make them malleable.

2. Heating: The preheated billets are then placed into a furnace where they are heated to temperatures between 400°F and 900°F (approximately 200°C to 480°C). This heating allows the aluminum to become soft enough for extrusion without turning molten.

3. Extrusion: Once heated, the billet is loaded into an extrusion press. A hydraulic ram applies immense pressure (up to 15,000 tons) to push the aluminum through a shaped die. The die determines the final shape of the extruded product.

4. Cooling: After emerging from the die, the extruded aluminum is cooled using water or air quenching to stabilize its properties and prevent deformation.

5. Cutting and Finishing: The cooled extrusions are cut to specified lengths using saws. Additional finishing processes such as anodizing or painting may be applied for enhanced durability and aesthetics.

6. Quality Control: Throughout the production process, quality control checks ensure that the extruded bars meet specified tolerances and performance standards.

Applications of Extrusion Bars

Extrusion bars have a wide range of applications across various industries due to their adaptability and strength:

- Construction: Aluminum extrusions are used in window frames, doors, roofing systems, and structural components due to their lightweight yet durable nature.

- Automotive: In the automotive industry, extruded aluminum parts contribute to weight reduction while maintaining strength, leading to improved fuel efficiency.

- Aerospace: The aerospace sector utilizes extruded components for aircraft frames and other structural elements where weight savings are critical.

- Consumer Products: Many household items such as furniture frames, appliances, and electronic enclosures utilize aluminum extrusions for their lightweight and corrosion-resistant properties.

- Industrial Applications: Extruded bars are commonly found in machinery components, conveyor systems, and material handling equipment due to their strength and versatility.

Benefits of Extrusion Bar Production

The extrusion process offers numerous advantages that make it a preferred choice for manufacturers:

- Cost-Effectiveness: Extrusion is generally less expensive than other manufacturing methods like casting or machining because it minimizes waste material and reduces secondary processing costs.

- Design Flexibility: The ability to create complex shapes allows designers to innovate freely without being constrained by traditional manufacturing limitations.

- Material Efficiency: The extrusion process can produce long lengths of material with consistent cross-sections, reducing scrap rates compared to other methods.

- High Strength-to-Weight Ratio: Aluminum extrusions possess excellent mechanical properties while being lightweight, making them ideal for applications where weight is a concern.

- Surface Finish Options: Extruded products can be easily anodized or painted for aesthetic appeal and enhanced corrosion resistance.

Why Is Extrusion Bar Production Important for Manufacturing?

The significance of extrusion bar production in manufacturing cannot be overstated. Here are several reasons why it holds such importance:

- Innovation in Design: As industries evolve, there is a growing demand for innovative designs that meet specific performance criteria. The versatility of extrusion allows engineers to create custom profiles tailored to unique applications.

- Sustainability: Aluminum is highly recyclable, making extrusion an environmentally friendly option. Using recycled aluminum reduces energy consumption and resource depletion compared to primary aluminum production.

- Meeting Industry Standards: Many industries have stringent standards regarding material performance and safety. The extrusion process can be precisely controlled to produce materials that meet these high standards consistently.

- Global Demand: With increasing urbanization and infrastructure development worldwide, the demand for lightweight yet strong materials continues to rise. Aluminum extrusion meets this demand effectively across various sectors.

Emerging Trends in Aluminum Extrusion

As technology advances, several emerging trends are reshaping the landscape of aluminum extrusion:

1. Sustainability Initiatives: Manufacturers are increasingly focusing on reducing carbon emissions throughout the production process. Innovations such as precision extrusion technology allow for thinner profiles while maintaining structural integrity, thus minimizing material usage and energy consumption[3][9].

2. Integration of Artificial Intelligence (AI): AI is being incorporated into various aspects of the extrusion process, including predictive maintenance and die design optimization. This integration enhances operational efficiency and product quality by analyzing large datasets[3][9].

3. Rapid Prototyping Capabilities: The ability to quickly prototype designs using aluminum extrusions enables faster product development cycles. This agility allows manufacturers to respond swiftly to market demands[2][4].

4. Advanced Finishing Techniques: New surface treatments enhance not only the aesthetic appeal but also the functional properties of extruded products. Techniques such as anodizing improve corrosion resistance while adding color options[12][10].

5. Higher Strength Alloys Development: Ongoing research into higher strength aluminum alloys is particularly relevant for automotive applications where durability is paramount[3][8].

Challenges in Aluminum Extrusion

Despite its many advantages, aluminum extrusion also faces certain challenges:

- Initial Setup Costs: While tooling costs for dies are relatively low compared to other methods like injection molding or casting, initial setup costs can still be significant depending on complexity[4][10].

- Material Limitations: Not all alloys are suitable for every application; understanding material properties is crucial for successful outcomes in specific environments[1][12].

- Quality Control Issues: Maintaining consistent quality throughout large production runs can be challenging due to variations in temperature control during heating or cooling processes[3][10].

Conclusion

In conclusion, extrusion bar production is an essential manufacturing process that shapes materials into versatile forms suitable for a wide range of applications. Its cost-effectiveness, design flexibility, sustainability initiatives, and emerging technological advancements make it a preferred choice across industries such as construction, automotive, aerospace, consumer products, and more. As technology continues to advance and industries evolve, the importance of extrusion will only continue to grow.

FAQ

1. What types of materials can be extruded?

Extrusion primarily involves metals like aluminum but can also include plastics and ceramics depending on specific applications.

2. How does the extrusion process differ from casting?

While casting involves pouring molten material into molds, extrusion forces solid or semi-solid material through a die to create continuous shapes with specific cross-sections.

3. What industries benefit most from aluminum extrusion?

Industries such as construction, automotive, aerospace, consumer goods manufacturing, and industrial equipment heavily rely on aluminum extrusion for its lightweight yet strong properties.

4. Can custom shapes be created through extrusion?

Yes! One of the key benefits of extrusion is its ability to produce custom shapes tailored to specific design requirements without significant additional costs.

5. What finishing options are available for extruded products?

Extruded products can undergo various finishing processes including anodizing for corrosion resistance or painting for aesthetic purposes.

Citations:

[1] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[2] https://flowstore.com/understand-aluminium-extrusion-modern-manufacturing/

[3] https://profileprecisionextrusions.com/the-evolution-of-aluminum-extrusions-emerging-trends-and-technologies/

[4] https://www.tfgusa.com/understanding-extrusion-a-fundamental-manufacturing-process/

[5] https://www.belcoind.com/the-benefits-of-designing-with-aluminum-extrusions/

[6] https://www.confectioneryproduction.com/feature/36288/focus-exploring-behind-the-scenes-of-extrusion-technology-for-confectionery/

[7] https://www.sunrise-metal.com/what-benefits-and-applications-are-there-for-machined-aluminum-extrusion/

[8] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[9] https://www.otalum.com/future-developments-and-trends-in-industrial-aluminum-extrusion-technology.html

[10] https://aec.org/features-benefits

[11] https://plasticextrusiontech.net/what-are-the-benefits-of-using-plastic-extrusions-over-other-materials/

[12] https://www.howardprecision.com/benefits-of-aluminum-extrusions/

[13] https://www.southwest-aluminum.com/news/aluminum-extruded-rod-latest-developments-ma-83349274.html

[14] https://paulmurphyplastics.com/industry-news-blog/extrusion-process-working-types-application-advantages-and-disadvantages/

[15] https://www.gabrian.com/what-are-aluminum-extrusions-used-for/

[16] https://www.grandviewresearch.com/industry-analysis/aluminum-extrusion-market

[17] https://www.wileymetal.com/five-common-applications-of-aluminum-extrusion/

[18] https://www.howardprecision.com/what-is-an-aluminum-extrusion-and-what-are-aluminum-extrusions-used-for/

[19] https://www.researchgate.net/publication/349399385_Recent_Development_Challenges_and_Prospects_of_Extrusion_Technology

[20] https://hitopindustrial.com/aluminum-extrusion-process/

[21] https://www.eganfoodtech.com/news?tag=In+the+News

[22] http://scaluminum.com/2022/02/benefits-of-aluminum-extrusion-vs-other-types-of-production/

[23] https://www.supplysidesj.com/market-trends-analysis/extrusion-processing-new-whole-grain-opportunities