Content Menu

● Understanding Aluminum Extrusion Linear Rail

>> The Extrusion Process

>> Key Features of Aluminum Extrusion Linear Rail

● How Aluminum Extrusion Linear Rail Works

>> Types of Bearing Systems

>> Rail Profiles

● Applications of Aluminum Extrusion Linear Rail

>> 1. 3D Printing and CNC Machines

>> 2. Automation and Robotics

>> 3. Packaging and Conveyor Systems

>> 4. Medical Equipment

>> 5. Automotive Manufacturing

● Advantages of Aluminum Extrusion Linear Rail

● Installation and Maintenance

>> Installation Tips

>> Maintenance Best Practices

● Future Trends in Aluminum Extrusion Linear Rail

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What are the main advantages of using aluminum extrusion linear rail?

>> 2. How does aluminum extrusion linear rail compare to steel linear guides?

>> 3. What maintenance is required for aluminum extrusion linear rail systems?

>> 4. Can aluminum extrusion linear rail be used in outdoor or harsh environments?

>> 5. What factors should be considered when selecting an aluminum extrusion linear rail system?

● Citations:

Aluminum extrusion linear rail is a versatile and efficient component used in various industries for precise linear motion applications. This innovative technology combines the strength and lightweight properties of aluminum with the precision of linear motion systems, resulting in a highly effective solution for many engineering and manufacturing needs.

Understanding Aluminum Extrusion Linear Rail

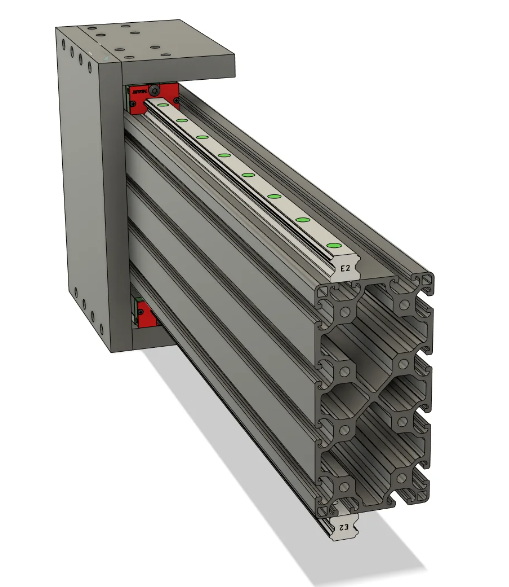

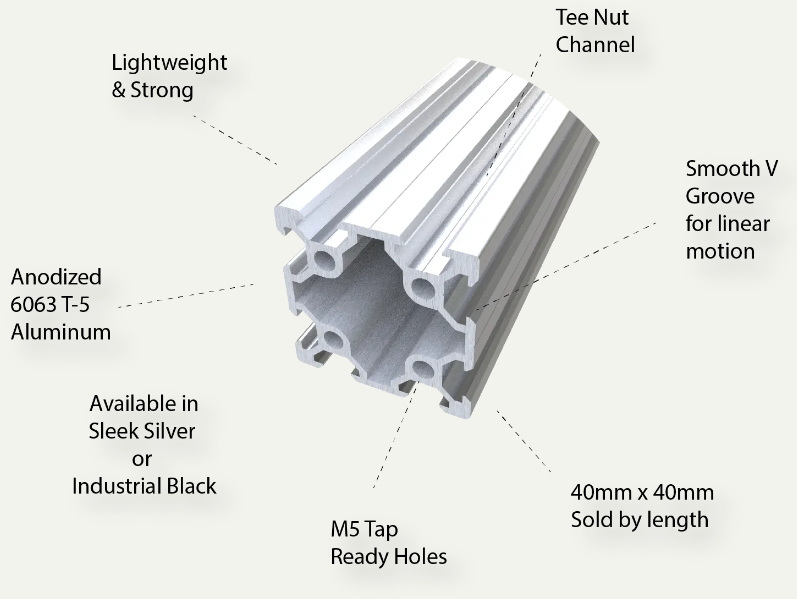

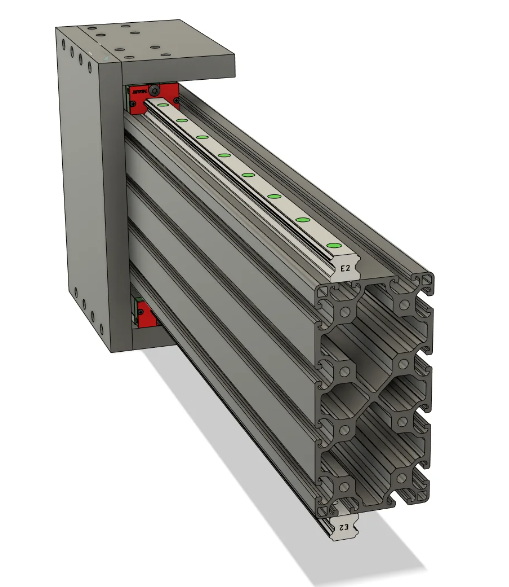

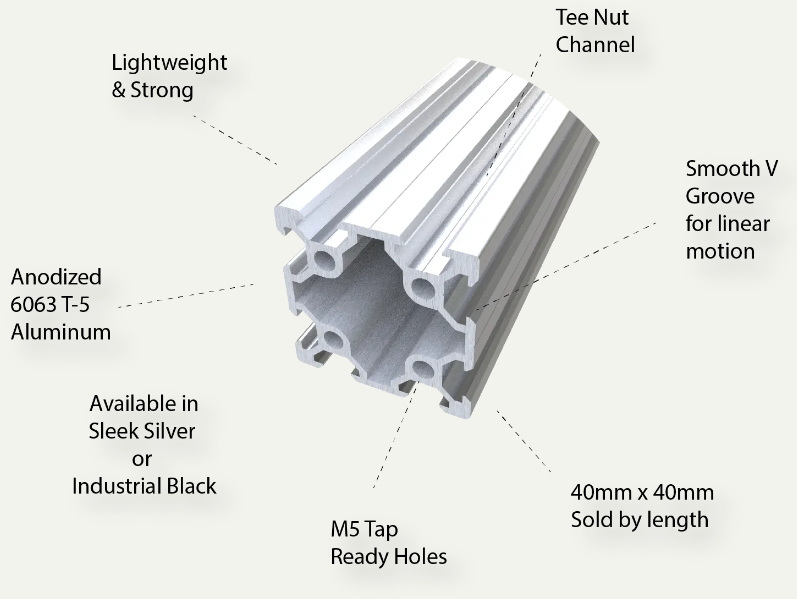

Aluminum extrusion linear rail is a mechanical component designed to provide smooth, accurate, and low-friction linear motion. It consists of two main parts: the rail itself, which is an extruded aluminum profile, and the bearing blocks or carriages that move along the rail. The extrusion process allows for the creation of complex cross-sectional shapes that can incorporate features like V-grooves, T-slots, or other specialized profiles to accommodate different types of bearings and attachments.

The Extrusion Process

The manufacturing of aluminum extrusion linear rail begins with the extrusion process. Aluminum billets are heated to a malleable state and then forced through a die that shapes the metal into the desired profile. This process allows for the creation of long, continuous sections of rail with precise and consistent dimensions.

Key Features of Aluminum Extrusion Linear Rail

1. Lightweight yet rigid: Aluminum offers an excellent strength-to-weight ratio, making it ideal for applications where weight is a concern.

2. Corrosion-resistant: Aluminum naturally forms a protective oxide layer, providing good resistance to corrosion.

3. Customizable profiles: The extrusion process allows for a wide range of profile designs to suit specific application needs.

4. Modular and versatile: Many aluminum extrusion linear rail systems are designed to be modular, allowing for easy integration with other components and simple modifications.

5. Cost-effective: Compared to some other materials used in linear motion systems, aluminum extrusion can be a more economical choice.

How Aluminum Extrusion Linear Rail Works

The operation of aluminum extrusion linear rail is based on the principle of low-friction linear motion. The bearing blocks or carriages, which contain rolling elements such as ball bearings or rollers, move along the precisely machined surfaces of the aluminum rail.

Types of Bearing Systems

1. Ball Bearing Systems: These use small steel balls that roll between the carriage and the rail, providing smooth motion with low friction.

2. Roller Bearing Systems: These employ cylindrical rollers instead of balls, offering higher load capacity and stiffness.

3. Sliding Systems: Some designs use low-friction materials like PTFE or UHMW plastic for sliding contact with the rail, suitable for lighter loads or cost-sensitive applications.

Rail Profiles

Aluminum extrusion linear rail comes in various profiles to suit different applications:

1. V-Slot: Features a V-shaped groove that guides wheels or bearings, popular in DIY and light industrial applications.

2. T-Slot: Incorporates T-shaped channels for easy attachment of accessories and components.

3. C-Beam: Offers a C-shaped profile for increased rigidity and load-bearing capacity.

4. Dovetail: Provides a secure connection between the rail and carriage, often used in precision applications.

Applications of Aluminum Extrusion Linear Rail

The versatility and performance of aluminum extrusion linear rail make it suitable for a wide range of applications across various industries:

1. 3D Printing and CNC Machines

In the world of additive manufacturing and computer numerical control (CNC) machining, aluminum extrusion linear rail plays a crucial role in ensuring precise movement of print heads or cutting tools.

2. Automation and Robotics

Industrial automation systems often rely on aluminum extrusion linear rail for tasks such as pick-and-place operations, assembly lines, and material handling.

3. Packaging and Conveyor Systems

The food and beverage industry, as well as logistics and warehousing, utilize aluminum extrusion linear rail in packaging machines and conveyor systems for efficient product handling.

4. Medical Equipment

Precision medical devices and laboratory equipment benefit from the smooth and accurate motion provided by aluminum extrusion linear rail systems.

5. Automotive Manufacturing

In automotive production lines, aluminum extrusion linear rail is used in various assembly and testing processes, contributing to improved efficiency and quality control.

Advantages of Aluminum Extrusion Linear Rail

1. Precision: The consistent profile and smooth surface of extruded aluminum rails enable high-precision linear motion.

2. Flexibility: The modular nature of many aluminum extrusion systems allows for easy customization and reconfiguration.

3. Durability: Aluminum's natural corrosion resistance and the robust design of linear rail systems ensure long-term reliability.

4. Cost-effectiveness: Compared to some alternative materials and technologies, aluminum extrusion linear rail often offers a more economical solution.

5. Ease of maintenance: Many aluminum extrusion linear rail systems are designed for easy cleaning and lubrication, reducing downtime and maintenance costs.

Installation and Maintenance

Proper installation and maintenance are crucial for optimal performance of aluminum extrusion linear rail systems. Here are some key considerations:

Installation Tips

1. Ensure a flat and level mounting surface to prevent distortion of the rail.

2. Use appropriate fasteners and follow recommended torque specifications.

3. Align multiple rails carefully to maintain parallelism and prevent binding.

Maintenance Best Practices

1. Regular cleaning to remove debris and contaminants.

2. Proper lubrication according to manufacturer recommendations.

3. Periodic inspection for wear, alignment, and tightness of components.

Future Trends in Aluminum Extrusion Linear Rail

As technology continues to advance, we can expect to see several developments in the field of aluminum extrusion linear rail:

1. Smart linear systems: Integration of sensors and IoT capabilities for real-time monitoring and predictive maintenance.

2. Advanced materials: Development of new aluminum alloys or composite materials for improved performance characteristics.

3. Eco-friendly solutions: Focus on sustainable manufacturing processes and recyclable materials.

4. Miniaturization: Creation of smaller, more compact linear rail systems for use in portable devices and compact machinery.

5. Enhanced surface treatments: Development of new coatings or surface modifications to further improve wear resistance and reduce friction.

Conclusion

Aluminum extrusion linear rail represents a significant advancement in linear motion technology, offering a combination of precision, versatility, and cost-effectiveness. Its wide range of applications across various industries demonstrates its importance in modern engineering and manufacturing processes. As technology continues to evolve, aluminum extrusion linear rail is likely to play an even more crucial role in shaping the future of automation, robotics, and precision machinery.

Frequently Asked Questions (FAQ)

1. What are the main advantages of using aluminum extrusion linear rail?

Aluminum extrusion linear rail offers several advantages, including:

- Lightweight yet rigid construction

- Corrosion resistance

- Customizable profiles

- Cost-effectiveness

- Easy integration with other components

- Smooth and precise linear motion

2. How does aluminum extrusion linear rail compare to steel linear guides?

While steel linear guides generally offer higher load capacity and stiffness, aluminum extrusion linear rail provides:

- Lighter weight

- Better corrosion resistance

- More design flexibility

- Often lower cost

- Easier customization and modification

3. What maintenance is required for aluminum extrusion linear rail systems?

To ensure optimal performance and longevity, maintenance should include:

- Regular cleaning to remove debris

- Proper lubrication as per manufacturer guidelines

- Periodic inspection for wear and alignment

- Checking and tightening of fasteners as needed

- Replacement of worn components when necessary

4. Can aluminum extrusion linear rail be used in outdoor or harsh environments?

Yes, aluminum extrusion linear rail can be used in outdoor or harsh environments with proper considerations:

- Choose appropriate seals and wipers to protect against contaminants

- Use corrosion-resistant materials for bearings and other components

- Consider additional surface treatments or coatings for enhanced protection

- Implement proper maintenance routines to address environmental challenges

5. What factors should be considered when selecting an aluminum extrusion linear rail system?

When choosing an aluminum extrusion linear rail system, consider the following factors:

- Load capacity and stiffness requirements

- Speed and acceleration needs

- Precision and accuracy demands

- Environmental conditions (temperature, humidity, contaminants)

- Space constraints and mounting options

- Compatibility with other system components

- Cost and long-term maintenance requirements

Citations:

[1] https://www.eztube.com/understanding-linear-rail-extrusions/

[2] https://www.reddit.com/r/hobbycnc/comments/1cl4jz0/aluminum_extrusion_with_linear_guide_rail_support/

[3] https://www.reddit.com/r/hobbycnc/comments/usam20/steel_rod_linear_bearings_vs_aluminum_profile/

[4] https://www.youtube.com/watch?v=Z7SHoHA9h54

[5] https://8020.net/blog/a-guide-to-8020-t-slot-linear-bearings.html

[6] https://us.openbuilds.com/v-slot-20x40-linear-rail/

[7] https://us.openbuilds.com/c-beam-linear-rail/