Content Menu

● Overview of POE Films

● Components of a POE Film Extrusion Production Line

● How Does the POE Film Extrusion Process Work?

● Advantages of Using a POE Film Extrusion Production Line

● Applications of POE Films

● Conclusion

● FAQ

>> 1. What materials are used in POE film production?

>> 2. How does the extrusion process affect film quality?

>> 3. What industries benefit from POE films?

>> 4. Can the production line be customized?

>> 5. What are the environmental benefits of using POE films?

● Citations:

In recent years, the demand for renewable energy sources has surged, leading to significant advancements in solar technology. One of the critical components in solar photovoltaic (PV) systems is the encapsulation film, which protects solar cells and enhances their efficiency. The "Poe Battery Film Extrusion Production Line" is a specialized manufacturing system designed to produce polyolefin elastomer (POE) films, primarily used in solar panels. This article will explore the intricacies of this production line, its components, and its operational mechanisms.

Overview of POE Films

Polyolefin elastomer (POE) films are essential in solar PV modules due to their excellent properties, including high light transmittance, UV resistance, and moisture barrier capabilities. These films serve as protective layers that encapsulate solar cells, ensuring durability and efficiency over the lifespan of the solar panels. The Poe Battery Film Extrusion Production Line is specifically engineered to produce these films with precision and consistency.

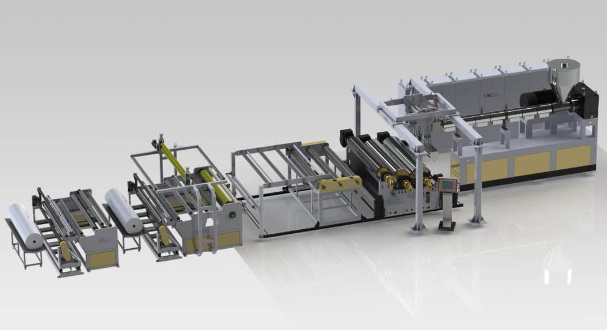

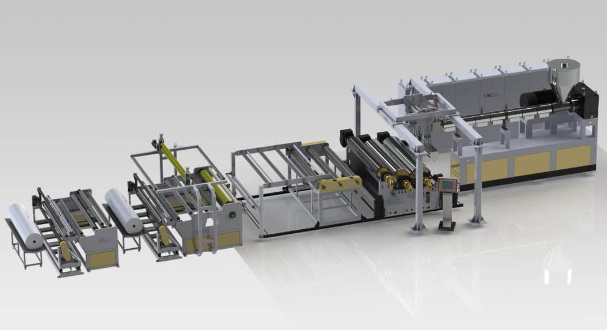

Components of a POE Film Extrusion Production Line

The Poe Battery Film Extrusion Production Line comprises several key components that work together to create high-quality POE films:

- Extruder: The heart of the production line, the extruder melts and homogenizes the raw materials before forming them into a film. Modern extrusion lines often utilize twin-screw extruders for better mixing and processing.

- Die Head: After the material is melted, it is forced through a die head that shapes the molten polymer into a flat film.

- Cooling System: Once extruded, the film must be cooled quickly to maintain its shape and properties. This is typically achieved using cooling rollers or air cooling systems.

- Calibration Unit: This unit ensures that the film maintains uniform thickness as it cools. It can include automatic thickness measurement systems that provide real-time feedback.

- Winding System: Finally, the finished film is wound onto rolls for storage and shipment. Automatic winding systems can enhance efficiency by minimizing waste and ensuring consistent roll sizes.

How Does the POE Film Extrusion Process Work?

The process of producing POE films involves several stages:

1. Material Preparation: Raw materials, including POE resin and various additives (such as UV stabilizers), are accurately measured and fed into the extruder.

2. Extrusion: The extruder heats the materials to their melting point, where they are mixed thoroughly. The molten polymer is then pushed through the die head to form a continuous sheet.

3. Cooling: The extruded film passes through cooling rollers or air jets to solidify it quickly while maintaining its desired properties.

4. Calibration: As the film cools, it enters a calibration unit that ensures uniform thickness across its width. This step is crucial for maintaining quality standards.

5. Winding: Finally, the cooled film is wound onto rolls by an automatic winding system, ready for further processing or distribution.

Advantages of Using a POE Film Extrusion Production Line

Utilizing a specialized Poe Battery Film Extrusion Production Line offers numerous advantages:

- High Efficiency: These production lines are designed for continuous operation, allowing for high output rates while maintaining quality standards.

- Cost-Effectiveness: By optimizing material usage and reducing waste through precise control systems, manufacturers can lower production costs significantly.

- Quality Control: Advanced monitoring systems ensure that each batch of film meets stringent quality requirements, reducing defects and improving overall product reliability.

- Flexibility: Many modern extrusion lines can produce various types of films by adjusting parameters such as temperature and speed, accommodating different product specifications.

Applications of POE Films

POE films produced on these extrusion lines are primarily used in:

- Solar Panels: Encapsulation of solar cells to protect them from environmental factors while enhancing light absorption.

- Automotive Glass: Providing safety features by preventing shattering upon impact.

- Building Materials: Used in glass curtain walls and other architectural applications where transparency and durability are required.

Conclusion

The Poe Battery Film Extrusion Production Line plays a vital role in producing high-quality POE films essential for modern solar energy applications. By leveraging advanced technology and efficient processes, manufacturers can meet growing demands for renewable energy solutions while ensuring product quality and cost-effectiveness. As technology continues to evolve, these production lines will likely incorporate even more innovative features to enhance efficiency and sustainability in film production.

FAQ

1. What materials are used in POE film production?

POE films are primarily made from polyolefin elastomer (POE) resin combined with various additives like UV stabilizers and adhesives to enhance performance characteristics.

2. How does the extrusion process affect film quality?

The extrusion process directly impacts film quality by determining factors such as thickness uniformity, transparency, and mechanical strength through precise temperature control and mixing techniques.

3. What industries benefit from POE films?

Industries such as solar energy, automotive manufacturing, construction, and packaging utilize POE films due to their excellent protective properties and durability.

4. Can the production line be customized?

Yes, many manufacturers offer customizable options for POE film extrusion lines to meet specific production requirements or accommodate different types of films.

5. What are the environmental benefits of using POE films?

POE films are known for their low environmental impact compared to traditional materials due to their recyclability and reduced reliance on harmful chemicals during production.

Citations:

[1] https://www.jwellextrusions.com/products/poe-film-extrusion-line/

[2] https://www.jwellextrusions.com/what-is-poe-film-for-solar.html

[3] https://www.gwellextrusion.com/product/solar-extrusion-line/eva-poe-solar-film-extrusion-line/

[4] https://www.youtube.com/watch?v=KwVhu9Y7b9Y

[5] https://www.jwellmachine.com/pvb-eva-poe-cast-film-extrusion-line/

[6] https://www.youtube.com/watch?v=-0fgnyW9xpM

[7] https://www.extruder.cn/eva-poe-plastic-film-machine.html

[8] https://www.jwellextrusions.com/the-production-method-of-poe-film-for-solar-photovoltaic-modules.html

[9] https://www.useon.com/eva-poe-solar-film-production-line/

[10] https://www.useon.com/pe-separator-for-lead-acid-battery/

[11] https://www.dwellextrusion.com/products/poe-film-extrusion-line/

[12] https://www.useon.com/uhmwpe-battery-separator-films/

[13] https://www.sml.at/cast-film-lines/libs

[14] https://www.plasticextrusion-machine.com/sale-41457643-poe-cast-film-extrusion-machine-with-2-5-film-layer-energy-efficient.html

[15] https://www.jwellextrusions.com/what-is-the-use-of-poe-film.html

[16] https://www.jwellplas.com/EVA-POE-PV-Battery-Film-Extrusion-Line.html

[17] https://www.shgwell.com/Lithium-battery-film-extrusion-line.html

[18] https://www.youtube.com/watch?v=EZQZrKxt1sc

[19] https://www.jwellextrusions.com/video/jwell-eva-poe-solar-film-extrusion-line.html

[20] https://www.jwellextrusions.com/video/sgp-solar-film-extrusion-line.html

[21] https://www.shgwell.com/product/EVA-solar-PV-encapsulation-film-production-line.html

[22] https://www.alibaba.com/product-detail/JWELL-EVA-POE-solar-Film-Extrusion_60839738126.html

[23] https://www.jwellextrusions.com/video/jwell-machinery-eva-poe-solar-film-extrusion-machine-extrusion-line.html

[24] https://www.useon.com/eva-poe-solar-film-production-line/

[25] https://www.pinterest.com/pin/evapoepvbsgp-film-extrusion-line--747245763185970981/

[26] https://www.jwellextrusions.com/video/jwell-machinery-eva-poe-solar-film-extrusion-line.html

[27] https://www.nantonggwell.com/en/photo/EVA-solar-film-extrusion-machine.html

[28] https://www.youtube.com/watch?v=xkuzV2oEthU

[29] https://www.youtube.com/watch?v=hN0vilsXZsU

[30] https://www.shgwell.com/photo/Production-line-quantity-exceeds-1000-sets.html

[31] https://www.youtube.com/watch?v=RvFTM9baJdE

[32] https://www.wellsonmachinery.com/oemodm-factory-cast-film-production-line-eva-peva-cast-film-extrusion-line-wellson-product/

[33] https://www.jwellmachine.com/pvb-eva-poe-cast-film-extrusion-line/

[34] https://www.extruder.cn/eva-poe-plastic-film-machine.html

[35] https://www.useon.com/videos/

[36] https://www.shgwell.com/photo/EVA-POE-PV-film-extrusion-line.html