Content Menu

● Introduction to Extrusion Blow Molding

>> Structure of the Machine

● Working Principle

● Applications

● Benefits

● Installation and Maintenance

>> Installation

>> Maintenance

● Advanced Features and Technologies

● Market Trends and Future Developments

● Conclusion

● FAQ

>> 1. What materials can be used with a PC full automatic double station extrusion blow molding machine?

>> 2. How does the machine ensure consistent product quality?

>> 3. What are the typical applications of these machines?

>> 4. How does the double station feature enhance productivity?

>> 5. What kind of maintenance is required for these machines?

● Citations:

The PC full automatic double station extrusion blow molding machine is a sophisticated piece of equipment designed for the efficient production of hollow plastic containers. These machines are widely used in industries such as food packaging, beverages, pharmaceuticals, and chemicals. In this article, we will delve into the structure, working principle, applications, and benefits of these machines, as well as discuss their installation and maintenance.

Introduction to Extrusion Blow Molding

Extrusion blow molding is a process used to create hollow plastic products. It involves extruding a tube of molten plastic (parison) into a mold, where it is then inflated with compressed air to take the shape of the mold. This process is versatile and can produce a wide range of products, from small bottles to large containers.

Structure of the Machine

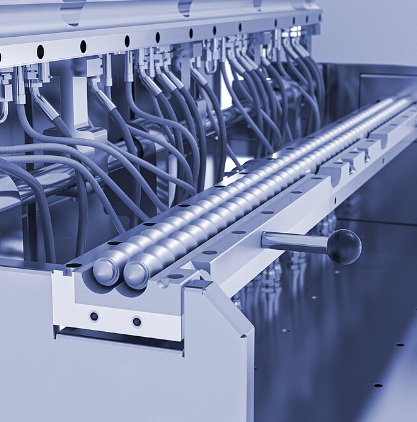

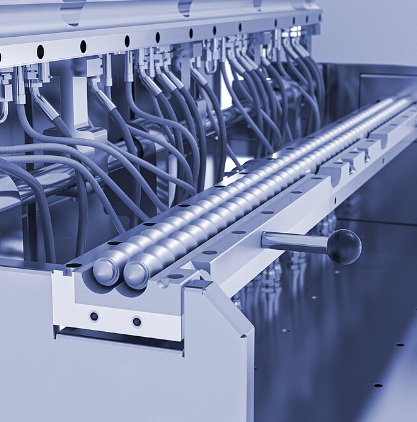

A typical PC full automatic double station extrusion blow molding machine consists of several key components:

1. Extruder: This is where the raw plastic material is melted and formed into a parison.

2. Mold: The mold gives the final shape to the product. In a double station machine, there are two molds, allowing for continuous production.

3. Clamping System: This system holds the mold in place during the blowing process.

4. Blowing System: Compressed air is used to inflate the parison inside the mold.

The machine's design often includes advanced features such as hydraulic systems for precise mold movement and positioning, as well as parison parameter controllers for automatic thickness adjustment[1]. Additionally, some models offer auto bottom mold release and auto circular jar cutting capabilities, enhancing efficiency and reducing labor costs[1].

Working Principle

The working principle of a PC full automatic double station extrusion blow molding machine involves several stages:

1. Extrusion: The plastic material is melted and extruded into a parison.

2. Mold Closing: The mold closes around the parison.

3. Blowing: Compressed air inflates the parison to the shape of the mold.

4. Cooling and Ejection: The product cools and is ejected from the mold.

This process is highly automated, with features like servo motors replacing traditional hydraulic systems in some models, which enhances energy efficiency and reduces environmental impact[2].

Applications

These machines are versatile and can produce a variety of products, including:

- Bottles for Beverages and Chemicals: Commonly made from HDPE or PP, these bottles are used for packaging water, juice, and chemical products.

- Cosmetic Containers: Used for packaging lotions, creams, shampoos, and other cosmetic products.

- Pharmaceutical Bottles: Manufactured to meet stringent hygiene standards for packaging medicines and healthcare products.

- Food Packaging Containers: Used for packaging food items such as sauces, condiments, and snacks.

The PC full automatic double station extrusion blow molding machine is particularly favored in industries requiring high cleanliness and precision, such as the food and pharmaceutical sectors[2].

Benefits

The PC full automatic double station extrusion blow molding machine offers several benefits:

- High Efficiency: Continuous production with two stations increases output significantly.

- Low Labor Costs: Fully automated, reducing the need for manual labor.

- Consistent Quality: Ensures uniform products with precise control over the molding process.

- Energy Efficiency: Some models use electric servo motors, which can save up to 70% of energy compared to traditional hydraulic systems[2].

Installation and Maintenance

Installation

Installation requires careful planning and execution. Typically, manufacturers send engineers to assist with setup, and clients are responsible for travel and accommodation costs. The client must also ensure that civil works are completed before installation begins[4].

Maintenance

Regular maintenance is crucial for optimal performance. This includes cleaning, lubricating moving parts, and checking for wear on components. Proper maintenance can extend the lifespan of the machine and ensure consistent product quality.

Advanced Features and Technologies

Modern PC full automatic double station extrusion blow molding machines often incorporate advanced technologies to enhance performance:

- Hydraulic and Pneumatic Systems: High-quality components from brands like FESTO and YUKEN ensure reliable operation and energy efficiency[6].

- Control Systems: Advanced control systems, such as those from B&R, provide precise control over the molding process[6].

- Servo Motors: Replacing traditional hydraulic systems, servo motors offer significant energy savings and reduced environmental impact[2].

Market Trends and Future Developments

The market for PC full automatic double station extrusion blow molding machines is evolving with a focus on cleaner production and energy efficiency. Electric blow molding machines are becoming increasingly popular due to their environmental benefits and cost savings[2]. As technology advances, we can expect to see more innovations in machine design and functionality.

Conclusion

The PC full automatic double station extrusion blow molding machine is a vital tool in the plastic manufacturing industry, offering efficiency, versatility, and cost-effectiveness. Its ability to produce a wide range of products makes it an essential asset for companies involved in packaging and container manufacturing.

FAQ

1. What materials can be used with a PC full automatic double station extrusion blow molding machine?

The machine can work with various materials such as HDPE, PE, PP, and PVC, depending on the intended application.

2. How does the machine ensure consistent product quality?

Consistency is achieved through precise control over the extrusion and blowing processes, ensuring uniform wall thickness and shape.

3. What are the typical applications of these machines?

Typical applications include producing bottles for beverages, chemicals, cosmetics, pharmaceuticals, and food packaging.

4. How does the double station feature enhance productivity?

The double station allows for continuous production, as one station can be preparing the next product while the other is in operation.

5. What kind of maintenance is required for these machines?

Regular maintenance includes cleaning, lubricating moving parts, and checking for wear on components to ensure optimal performance.

Citations:

[1] https://www.prm-taiwan.com/product/CM-S-D-T-F-H-2D-Series.html

[2] https://www.jwellextrusions.com/products/automatic-blow-molding-machine/

[3] https://www.cm-pet.com/msg/case-study.html

[4] https://www.tzdegree.com/extrusion-molding-machine/jerrycan-blow-molding-machine/full-automatic-double-station-extrusion-blow.html

[5] https://www.cm-pet.com/category-extrusion-blow-molding-machines.html

[6] https://m.automaticblowmouldingmachine.com/sale-26564118-high-speed-extrusion-blow-molding-machine-hdpe-bottles-double-station.html

[7] https://tongdachinamachine.en.made-in-china.com/product/CalUjSqrEfHd/China-Computerized-High-Speed-Double-Station-Extrusion-Blow-Molding-Machine-for-1L-2L-3L-Plastic-Bottles-Containers.html

[8] https://www.sciencedirect.com/topics/engineering/blow-molding

[9] https://blow-molding-machine.en.made-in-china.com/product/ueBEMHPVhDkR/China-Double-Station-HDPE-Automatic-Extrusion-Blow-Molding-Machinery.html

[10] https://www.alibaba.com/showroom/blow-moulding-machine-video.html

[11] https://jwellmachinery.en.made-in-china.com/product/HKrJeQMlJVUD/China-Full-Automatic-12L-Double-Station-Extrusion-Blow-Molding-Machine.html

[12] https://tongdachinamachine.en.made-in-china.com/product/yOAtsUdZwFrg/China-Automatic-Extrusion-Blow-Molding-Machine.html

[13] https://www.jwellextrusions.com/production-process-and-basic-principle-of-blow-molding-machine.html

[14] https://www.alibaba.com/product-detail/Fully-automatic-High-Quality-Double-Station_1600351831917.html

[15] https://www.alibaba.com/product-detail/Blow-Molding-Machine-5L-Blowing-Molding_1601185157090.html

[16] https://www.grafiati.com/en/literature-selections/blow-molding/dissertation/

[17] https://kingmachine.en.made-in-china.com/product/fvtmybEdCehV/China-Automatic-Double-Station-Extrusion-Blowing-Machine.html

[18] https://www.justdial.com/Navi-Mumbai/Blow-Moulding-Machine-Manufacturers-in-Taloja-Midc/nct-10049456

[19] https://www.directindustry.com/industrial-manufacturer/blow-molding-machine-80224.html

[20] https://www.cm-pet.com/pro-cm-fe-fully-electric-blow-molding-machine.html