Content Menu

● Understanding 80/20 Aluminum Extrusions

● Innovative Applications of 80/20 Aluminum Extrusion Accessories

>> Custom Workstations

>> Robotics and Automation

>> Display and Exhibit Stands

>> Safety Guards and Barriers

>> Furniture Design

>> Greenhouses and Garden Structures

>> Custom Racks and Shelving

>> Machine Frames

>> Prototyping and Product Development

>> Educational Projects

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of using 80/20 aluminum extrusions?

>> 2. Can 80/20 aluminum extrusions be used outdoors?

>> 3. How do I assemble 80/20 aluminum extrusions?

>> 4. Are there any limitations to using 80/20 aluminum extrusions?

>> 5. What industries commonly use 80/20 aluminum extrusions?

80/20 aluminum extrusion accessories have revolutionized the way we approach design and construction in various fields, from manufacturing to DIY projects. These versatile components allow for the creation of custom structures that are not only functional but also aesthetically pleasing. In this article, we will explore the innovative uses of 80/20 aluminum extrusion accessories, showcasing their applications across different industries and providing insights into how they can enhance your projects.

Understanding 80/20 Aluminum Extrusions

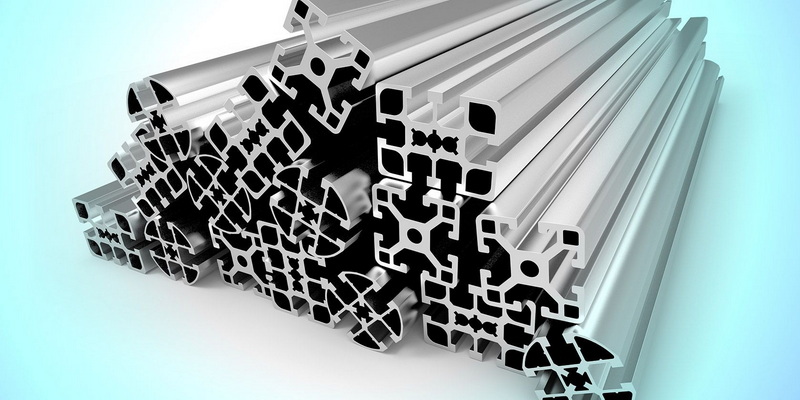

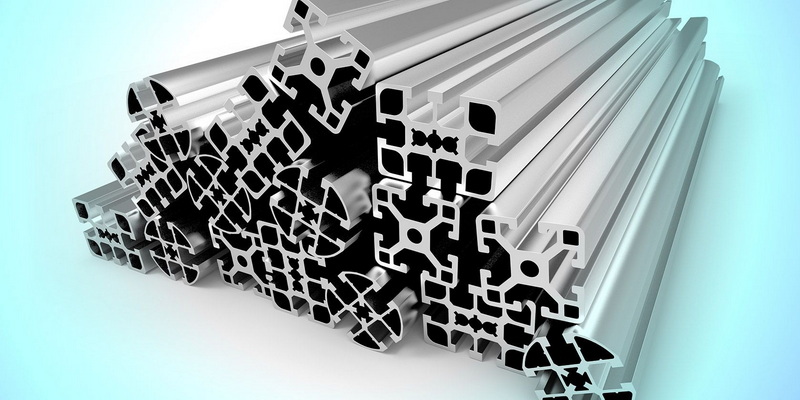

80/20 aluminum extrusions are T-slot profiles made from high-quality aluminum. The T-slot design allows for easy assembly and disassembly, making it an ideal choice for modular construction. These extrusions come in various shapes and sizes, enabling users to create everything from simple frames to complex machinery. The accessories that accompany these extrusions, such as brackets, connectors, and fasteners, further enhance their versatility.

Innovative Applications of 80/20 Aluminum Extrusion Accessories

Custom Workstations

One of the most popular uses of 80/20 aluminum extrusions is in the creation of custom workstations. These workstations can be tailored to fit specific tasks, whether in a manufacturing environment or a home workshop. By using aluminum extrusions, users can design ergonomic workspaces that enhance productivity and comfort. The ability to adjust the height and layout of the workstation allows for a personalized setup that can accommodate various tools and equipment.

Robotics and Automation

In the field of robotics, 80/20 aluminum extrusions are widely used to build frames and structures for robotic arms, mobile robots, and automation systems. The lightweight yet sturdy nature of aluminum makes it an excellent choice for these applications, allowing for precise movements and easy integration of components. The modular design of the extrusions enables engineers to quickly adapt their designs as technology evolves, making it easier to incorporate new features or improve existing systems.

Display and Exhibit Stands

Trade shows and exhibitions often require portable and adjustable display stands. 80/20 aluminum extrusions provide a robust solution for creating these stands, allowing for easy assembly and disassembly. The modular nature of the extrusions means that exhibitors can customize their displays to fit different spaces and requirements. This flexibility not only saves time during setup but also allows for creative designs that can attract more visitors.

Safety Guards and Barriers

In industrial settings, safety is paramount. 80/20 aluminum extrusions can be used to create safety guards and barriers around machinery, protecting workers from potential hazards. These structures can be designed to meet specific safety standards while allowing for visibility and access. By using aluminum extrusions, companies can ensure that their safety measures are both effective and compliant with regulations, reducing the risk of accidents in the workplace.

Furniture Design

The furniture industry has also embraced 80/20 aluminum extrusions for creating modern and minimalist designs. From tables and chairs to shelving units, the clean lines and structural integrity of aluminum allow for innovative furniture solutions that are both functional and stylish. Designers can experiment with different configurations and finishes, resulting in unique pieces that stand out in any environment. The durability of aluminum also ensures that these furniture items can withstand daily use while maintaining their aesthetic appeal.

Greenhouses and Garden Structures

For gardening enthusiasts, 80/20 aluminum extrusions can be used to build greenhouses and other garden structures. The lightweight nature of aluminum makes it easy to construct large frames that can support glass or plastic panels, creating a controlled environment for plants. This application is particularly beneficial for those looking to extend their growing season or cultivate delicate plants that require specific conditions. The modular design allows for easy expansion or modification of the greenhouse as needs change.

Custom Racks and Shelving

Storage solutions are essential in both home and industrial settings. 80/20 aluminum extrusions can be used to create custom racks and shelving units that maximize space and organization. The modular design allows for easy adjustments and expansions as needs change. Users can design their storage solutions to fit specific items, ensuring that everything has its place and is easily accessible. This level of customization can significantly improve efficiency in both personal and professional environments.

Machine Frames

In manufacturing, machine frames constructed from 80/20 aluminum extrusions provide a strong and lightweight foundation for various equipment. These frames can be designed to accommodate specific machinery, ensuring stability and ease of maintenance. The ability to quickly assemble and disassemble these frames allows for efficient repairs and upgrades, minimizing downtime in production processes. Additionally, the use of aluminum helps reduce the overall weight of the machinery, which can lead to energy savings during operation.

Prototyping and Product Development

For engineers and designers, 80/20 aluminum extrusions are invaluable in the prototyping phase of product development. The ability to quickly assemble and modify structures allows for rapid testing and iteration, leading to more efficient design processes. This flexibility is crucial in today's fast-paced market, where time-to-market can significantly impact a product's success. By utilizing aluminum extrusions, teams can create functional prototypes that accurately represent their final products, facilitating better feedback and improvements.

Educational Projects

In educational settings, 80/20 aluminum extrusions are often used for STEM projects and robotics competitions. Students can learn about engineering principles while building functional models and structures, fostering creativity and problem-solving skills. The hands-on experience gained from working with these materials can inspire the next generation of engineers and innovators. Schools and educational programs can benefit from the modularity of aluminum extrusions, allowing for a wide range of projects that can be adapted to different learning objectives.

Conclusion

The innovative uses of 80/20 aluminum extrusion accessories are vast and varied, making them a popular choice across multiple industries. Their versatility, ease of assembly, and structural integrity allow for creative solutions in workspaces, manufacturing, design, and education. As technology continues to evolve, the applications for these aluminum extrusions will undoubtedly expand, offering even more opportunities for innovation.

Frequently Asked Questions

1. What are the main benefits of using 80/20 aluminum extrusions?

The main benefits include versatility, ease of assembly, lightweight yet strong construction, and the ability to create custom designs.

2. Can 80/20 aluminum extrusions be used outdoors?

Yes, aluminum is resistant to corrosion, making it suitable for outdoor applications, such as garden structures and outdoor furniture.

3. How do I assemble 80/20 aluminum extrusions?

Assembly typically involves using T-slot connectors and fasteners, allowing for quick and easy construction without the need for specialized tools.

4. Are there any limitations to using 80/20 aluminum extrusions?

While they are highly versatile, the cost of aluminum extrusions can be higher than traditional materials like wood, and they may require specific accessories for certain applications.

5. What industries commonly use 80/20 aluminum extrusions?

Industries such as manufacturing, robotics, education, and furniture design frequently utilize 80/20 aluminum extrusions for various applications.