Content Menu

● Introduction

● Advantages of Bosch Rexroth Aluminum Solutions

>> Lightweight and Durable

>> Versatility in Design

>> Easy Assembly and Modification

● Applications of Bosch Rexroth Aluminum Solutions

>> Manufacturing and Automation

>> Custom Fabrication

>> Safety and Ergonomics

● Comparison with Other Materials

>> Aluminum vs. Steel

>> Aluminum vs. Plastic

● Innovative Applications in Various Industries

>> Automotive Industry

>> Aerospace Industry

>> Electronics Industry

● Conclusion

● Related Questions

>> 1. What are the key benefits of using Bosch Rexroth aluminum solutions in manufacturing?

>> 2. How do Bosch Rexroth aluminum profiles compare to steel?

>> 3. Can Bosch Rexroth aluminum solutions be customized for specific applications?

>> 4. What industries benefit the most from Bosch Rexroth aluminum solutions?

>> 5. How do Bosch Rexroth aluminum solutions contribute to workplace safety?

Introduction

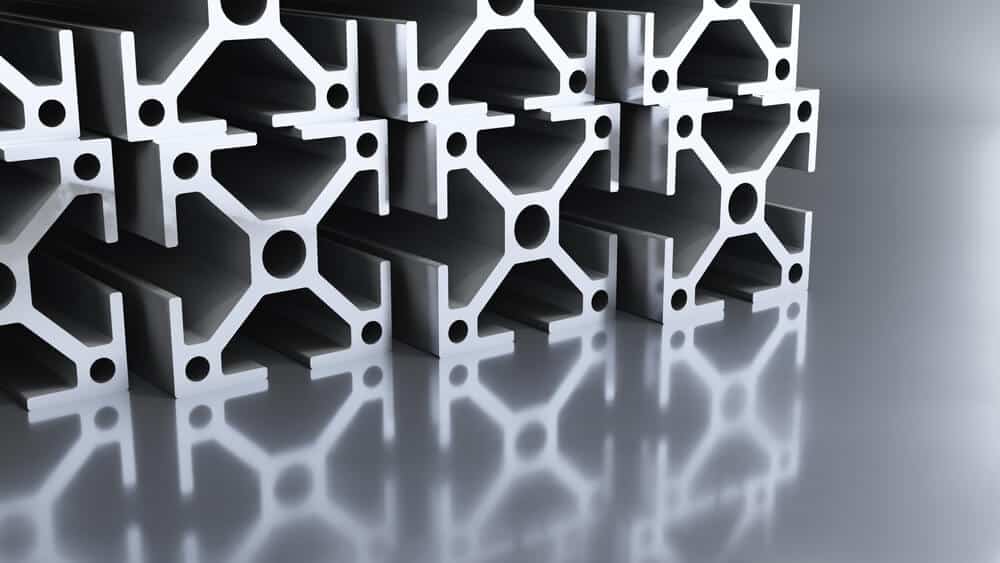

Bosch Rexroth is a global leader in drive and control technologies, renowned for its innovative solutions in aluminum extrusion. The versatility and strength of aluminum make it an ideal material for a wide range of applications across various industries. From manufacturing to automation, Bosch Rexroth aluminum solutions provide the structural integrity and flexibility needed to create efficient and effective systems. This article explores the innovative applications that can be developed using Bosch Rexroth aluminum solutions, highlighting their benefits and showcasing real-world examples.

Advantages of Bosch Rexroth Aluminum Solutions

Lightweight and Durable

One of the most significant advantages of Bosch Rexroth aluminum solutions is their lightweight nature. Aluminum has a high strength-to-weight ratio, making it an excellent choice for applications where weight reduction is crucial. This characteristic is particularly beneficial in industries such as automotive and aerospace, where every gram counts. The durability of aluminum also ensures that structures can withstand harsh environments, making them suitable for outdoor applications and industrial settings.

Versatility in Design

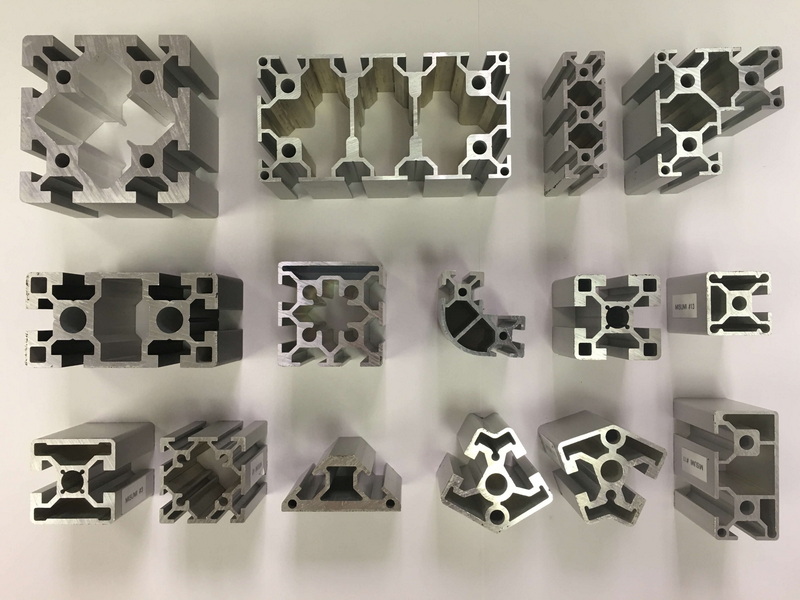

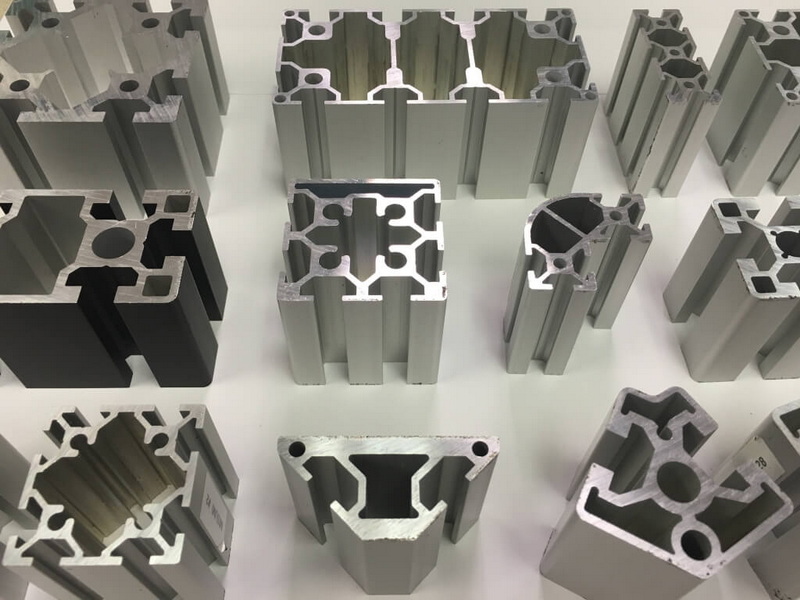

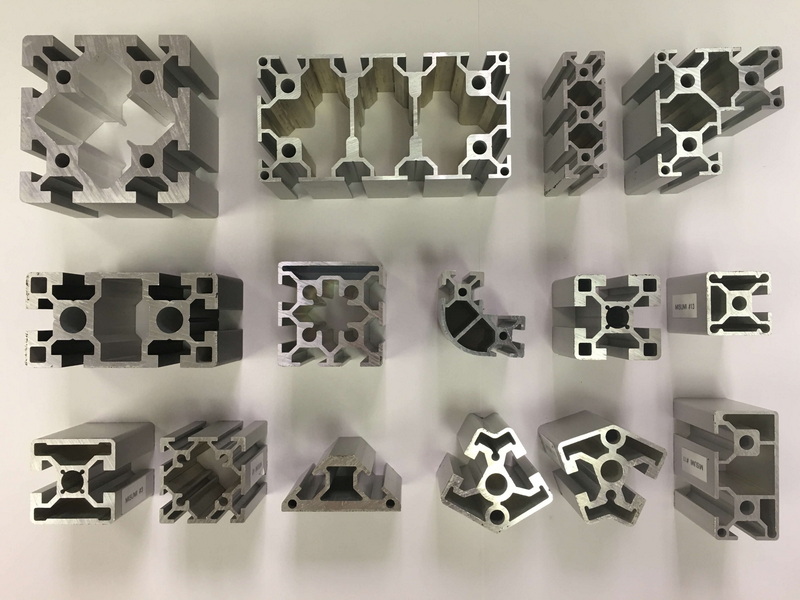

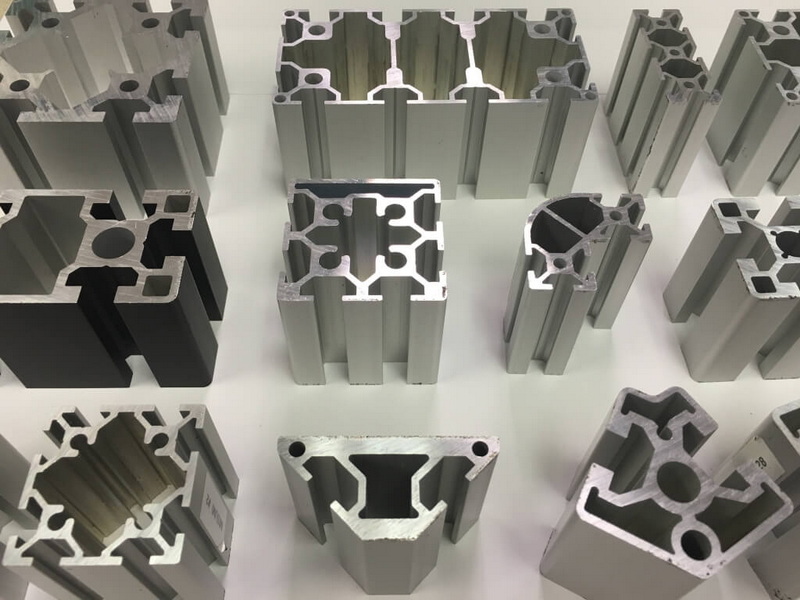

Bosch Rexroth aluminum profiles are designed to be modular, allowing for a wide range of configurations and designs. This versatility enables engineers and designers to create custom solutions tailored to specific needs. Whether it's a simple frame for a workstation or a complex assembly line, the adaptability of aluminum profiles makes them an ideal choice for various applications.

For instance, in the manufacturing sector, Bosch Rexroth aluminum solutions can be used to construct assembly lines that are easily adjustable to accommodate different products. This flexibility not only enhances productivity but also reduces downtime during product changes.

Easy Assembly and Modification

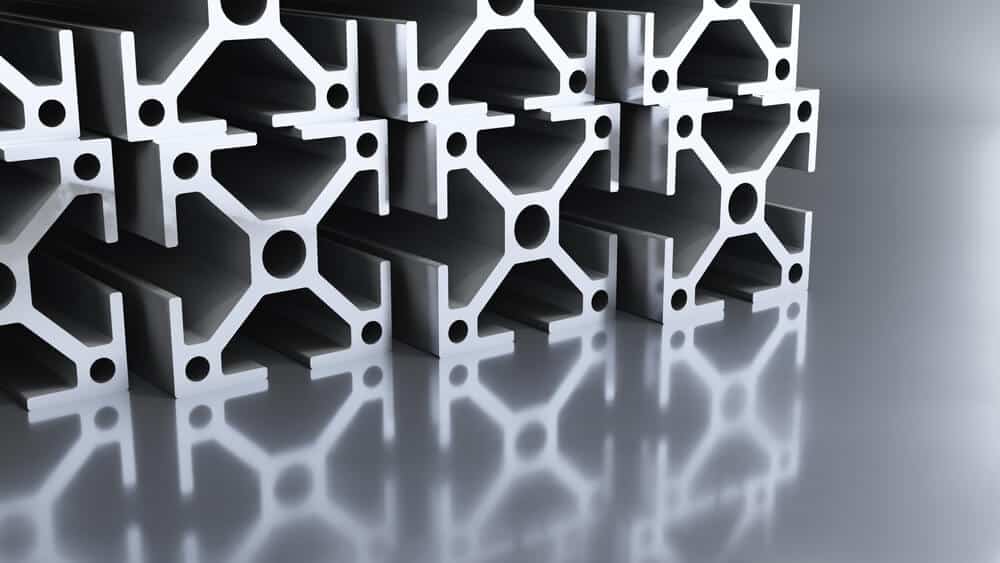

The T-slot design of Bosch Rexroth aluminum extrusions allows for quick and easy assembly. Components can be connected using standard fasteners, eliminating the need for specialized tools or extensive training. This ease of assembly is particularly advantageous in fast-paced environments where time is of the essence.

Moreover, the modular nature of these solutions means that modifications can be made with minimal effort. If a production line needs to be reconfigured, it can be done quickly without the need for extensive downtime or costly alterations.

Applications of Bosch Rexroth Aluminum Solutions

Manufacturing and Automation

In the realm of manufacturing, Bosch Rexroth aluminum solutions are widely used to create efficient and effective production systems. For example, assembly lines constructed with aluminum profiles can be easily customized to fit the specific needs of a production process. This adaptability allows manufacturers to optimize their workflows, reducing lead times and increasing output.

Additionally, Bosch Rexroth's aluminum solutions can be integrated with automation technologies, such as robotics and conveyor systems. This integration enhances the efficiency of manufacturing processes, allowing for greater precision and consistency in production.

Custom Fabrication

Custom fabrication is another area where Bosch Rexroth aluminum solutions shine. The ability to create bespoke structures tailored to unique requirements is a significant advantage in industries such as automotive, aerospace, and electronics. For instance, a company may require a specialized frame for a new product line. Using Bosch Rexroth aluminum profiles, engineers can design and fabricate a solution that meets the exact specifications needed for that product.

Case studies have shown that companies utilizing Bosch Rexroth aluminum solutions for custom fabrication have experienced increased efficiency and reduced costs. The modularity of the profiles allows for quick adjustments and modifications, ensuring that the final product meets the desired standards.

Safety and Ergonomics

Safety is a paramount concern in any industrial setting. Bosch Rexroth aluminum solutions contribute to creating safer work environments by allowing for the design of ergonomic workstations and safety barriers. The lightweight nature of aluminum makes it easier to construct structures that can be easily moved or adjusted, ensuring that workers have a safe and comfortable workspace.

For example, ergonomic workstations designed with Bosch Rexroth aluminum profiles can be tailored to the specific needs of employees, reducing the risk of injury and enhancing productivity. Additionally, safety barriers made from aluminum profiles can be easily integrated into production areas to protect workers from potential hazards.

Comparison with Other Materials

Aluminum vs. Steel

When comparing aluminum to steel, several factors come into play. While steel is known for its strength, it is also significantly heavier than aluminum. This weight difference can lead to increased transportation costs and challenges in handling. In contrast, Bosch Rexroth aluminum solutions provide a lightweight alternative without compromising structural integrity.

Furthermore, aluminum is naturally resistant to corrosion, making it a more suitable choice for outdoor applications or environments where exposure to moisture is a concern. This resistance reduces maintenance costs and extends the lifespan of structures built with aluminum profiles.

Aluminum vs. Plastic

While plastic is often used in various applications due to its lightweight and cost-effective nature, it lacks the strength and durability of aluminum. Bosch Rexroth aluminum solutions offer a robust alternative that can withstand higher loads and provide greater stability. Additionally, aluminum profiles can be recycled, making them a more environmentally friendly option compared to plastic.

Innovative Applications in Various Industries

Automotive Industry

In the automotive industry, Bosch Rexroth aluminum solutions are used to create lightweight structures that enhance fuel efficiency. For example, manufacturers can design chassis and frames using aluminum profiles, reducing the overall weight of vehicles. This weight reduction not only improves fuel economy but also enhances performance.

Aerospace Industry

The aerospace industry also benefits from the use of Bosch Rexroth aluminum solutions. Aircraft components made from aluminum are lighter and more fuel-efficient, contributing to lower operational costs. Additionally, the corrosion resistance of aluminum is crucial in aerospace applications, where exposure to harsh environmental conditions is common.

Electronics Industry

In the electronics industry, Bosch Rexroth aluminum profiles are used to create enclosures and racks for electronic components. The lightweight nature of aluminum allows for easy installation and modification, while its durability ensures that sensitive equipment is protected from damage.

Conclusion

Bosch Rexroth aluminum solutions offer a wealth of innovative applications across various industries. Their lightweight, durable, and versatile nature makes them an ideal choice for manufacturing, automation, custom fabrication, and safety applications. By leveraging the advantages of aluminum profiles, businesses can enhance efficiency, reduce costs, and create safer work environments.

As industries continue to evolve, the demand for innovative solutions will only increase. Bosch Rexroth aluminum solutions are well-positioned to meet these demands, providing the structural integrity and flexibility needed to drive progress in manufacturing and beyond.

Related Questions

1. What are the key benefits of using Bosch Rexroth aluminum solutions in manufacturing?

Bosch Rexroth aluminum solutions offer lightweight, durable, and versatile options that enhance efficiency, reduce costs, and allow for easy assembly and modification in manufacturing processes.

2. How do Bosch Rexroth aluminum profiles compare to steel?

Aluminum profiles are lighter than steel, making them easier to handle and transport. They also offer corrosion resistance, reducing maintenance costs and extending the lifespan of structures.

3. Can Bosch Rexroth aluminum solutions be customized for specific applications?

Yes, Bosch Rexroth aluminum solutions are modular and can be easily customized to meet the unique requirements of various applications, including manufacturing, automotive, and aerospace.

4. What industries benefit the most from Bosch Rexroth aluminum solutions?

Industries such as automotive, aerospace, electronics, and manufacturing benefit significantly from Bosch Rexroth aluminum solutions due to their lightweight, durable, and versatile nature.

5. How do Bosch Rexroth aluminum solutions contribute to workplace safety?

Bosch Rexroth aluminum solutions can be used to design ergonomic workstations and safety barriers, creating safer work environments and reducing the risk of injury for employees.