Content Menu

● Understanding Aluminum Extrusion

>> The Aluminum Extrusion Process

● Key Benefits of 3 4 Aluminum Extrusion

● Industries Utilizing 3 4 Aluminum Extrusion

>> 1. Automotive Industry

>> 2. Construction Industry

>> 3. Aerospace Industry

>> 4. Electronics Industry

>> 5. Furniture Industry

>> 6. Renewable Energy Sector

>> 7. Medical Equipment Manufacturing

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusion over other materials?

>> 2. How does the manufacturing process of aluminum extrusion work?

>> 3. Can you customize the shapes of aluminum extrusions?

>> 4. What industries benefit most from using 3 4 aluminum extrusion?

>> 5. Is aluminum extrusion environmentally friendly?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into specific cross-sectional profiles for a wide range of applications. Among the various sizes available, 3 4 aluminum extrusion is particularly popular due to its versatility and strength. This article explores the industries that rely on 3 4 aluminum extrusion, highlighting its applications, benefits, and the reasons behind its widespread use.

Understanding Aluminum Extrusion

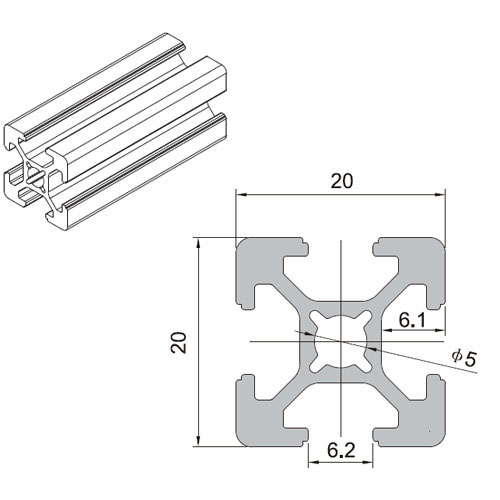

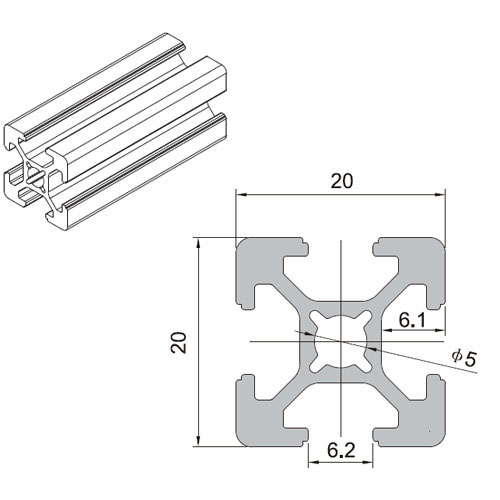

Aluminum extrusion involves forcing heated aluminum through a die to create a specific shape. The process allows for intricate designs and consistent profiles, making it ideal for various applications. The 3 4 aluminum extrusion size refers to profiles that are approximately three-quarters of an inch in width, which strikes a balance between strength and weight.

The Aluminum Extrusion Process

The aluminum extrusion process can be broken down into several key steps:

1. Billet Preparation: The process begins with an aluminum billet, which is a solid block of aluminum alloy. The billet is heated to a specific temperature to make it malleable.

2. Extrusion: Once heated, the billet is placed in an extrusion press. A ram pushes the billet through a die, shaping it into the desired profile.

3. Cooling: After exiting the die, the extruded profile is cooled, typically using air or water.

4. Cutting and Finishing: The cooled extrusions are cut to length and may undergo additional processes such as anodizing, painting, or machining to meet specific requirements.

This efficient process allows manufacturers to produce long lengths of consistent profiles tailored to their needs.

Key Benefits of 3 4 Aluminum Extrusion

Before diving into specific industries, it's essential to understand why 3 4 aluminum extrusion is favored:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport. This property is particularly beneficial in industries where weight reduction can lead to cost savings and improved performance.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer when exposed to air, enhancing its durability in various environments. This makes it suitable for outdoor applications where exposure to moisture and other elements is a concern.

- Versatility: The ability to create custom shapes allows for diverse applications across different sectors. Manufacturers can design profiles that meet specific functional requirements without compromising aesthetics.

- Cost-Effective: While the initial cost may be higher than some materials, the long-term savings from durability and low maintenance make it economical. Additionally, the lightweight nature of aluminum can reduce shipping costs.

- Recyclability: Aluminum is highly recyclable without loss of properties, making it an environmentally friendly choice. Recycling aluminum saves up to 95% of the energy required to produce new aluminum from ore.

Industries Utilizing 3 4 Aluminum Extrusion

1. Automotive Industry

The automotive industry is one of the largest consumers of 3 4 aluminum extrusion. Manufacturers use these profiles for:

- Structural Components: Aluminum extrusions are used in vehicle frames and body structures due to their strength-to-weight ratio.

- Chassis Parts: Lightweight aluminum components help improve fuel efficiency while maintaining structural integrity during crashes.

- Heat Exchangers: The excellent thermal conductivity of aluminum makes it ideal for heat exchangers used in engines and HVAC systems.

The shift towards electric vehicles (EVs) has further increased the demand for lightweight materials like aluminum, as manufacturers strive to enhance battery efficiency and overall vehicle performance.

2. Construction Industry

In construction, 3 4 aluminum extrusion is utilized in various applications such as:

- Window Frames: Aluminum's resistance to corrosion makes it an ideal choice for window frames that must withstand the elements while providing thermal insulation.

- Door Frames: The lightweight nature of aluminum allows for easy installation while ensuring durability and security.

- Curtain Walls: Architectural designs often incorporate large glass panels supported by aluminum extrusions, providing both aesthetic appeal and structural support.

The aesthetic appeal and durability of aluminum make it a preferred choice for modern architecture, contributing to energy-efficient buildings with reduced maintenance costs.

3. Aerospace Industry

The aerospace sector demands materials that are both lightweight and strong. 3 4 aluminum extrusion is used in:

- Aircraft Frames: Aluminum's high strength-to-weight ratio is crucial for aircraft structures that must endure significant stress during flight.

- Interior Components: Extruded profiles are used in cabin interiors for overhead bins, seat frames, and other fixtures due to their lightweight properties.

- Support Structures: Many support structures within aircraft utilize aluminum extrusions because they provide necessary strength without adding excessive weight.

The ability to withstand extreme conditions makes aluminum an ideal choice for aircraft manufacturing, where safety and performance are paramount.

4. Electronics Industry

In electronics, 3 4 aluminum extrusion serves as:

- Heat Sinks: Effective thermal management is critical in electronics; extruded aluminum profiles dissipate heat efficiently from components such as CPUs and GPUs.

- Enclosures: Many electronic devices use aluminum enclosures for protection against electromagnetic interference (EMI) while providing a sleek appearance.

- Structural Supports: Lightweight yet strong extrusions are often used as supports in electronic equipment racks and mounting systems.

The excellent thermal conductivity of aluminum helps dissipate heat effectively, which is crucial for electronic devices that generate heat during operation.

5. Furniture Industry

The furniture industry has embraced 3 4 aluminum extrusion for creating:

- Frameworks for Tables and Chairs: Aluminum's lightweight nature allows designers to create modern furniture pieces that are easy to move while maintaining stability.

- Decorative Elements: Extruded profiles can be designed with intricate patterns or finishes that enhance the aesthetic value of furniture items.

- Lightweight Shelving Units: Aluminum shelving units provide strength without adding excessive weight, making them ideal for both residential and commercial use.

Aluminum provides a modern look while being easy to maintain; its resistance to rust ensures longevity even in high-humidity environments like kitchens or bathrooms.

6. Renewable Energy Sector

With the rise of renewable energy technologies, 3 4 aluminum extrusion plays a crucial role in:

- Solar Panel Frames: Lightweight yet sturdy frames made from extruded aluminum support solar panels while resisting corrosion from environmental exposure.

- Wind Turbine Components: Aluminum's strength-to-weight ratio makes it suitable for various components within wind turbines, including towers and blades.

- Support Structures for Renewable Installations: Many renewable energy setups use extruded aluminum profiles due to their durability and ease of installation.

Aluminum's resistance to corrosion makes it suitable for outdoor applications where exposure to moisture and other elements is a concern.

7. Medical Equipment Manufacturing

In the medical field, precision and reliability are paramount. 3 4 aluminum extrusion is used in:

- Medical Device Housings: Extruded profiles provide robust protection for sensitive electronic components within medical devices while ensuring compliance with safety standards.

- Support Structures for Imaging Equipment: Lightweight yet strong structures support heavy imaging equipment like MRI machines without compromising stability or safety.

- Lightweight Carts and Trolleys: Hospitals often utilize carts made from extruded aluminum due to their maneuverability and ease of cleaning in sterile environments.

Its non-reactive properties ensure safety in medical environments where hygiene is critical.

Conclusion

The versatility of 3 4 aluminum extrusion makes it an essential material across various industries, from automotive to aerospace and beyond. Its unique properties—lightweight yet strong, corrosion-resistant, customizable—allow manufacturers to innovate continually and improve their products. As industries evolve and demand more sustainable solutions, the role of aluminum extrusion will likely expand further.

By utilizing this material effectively, companies can enhance product performance while reducing environmental impact through recycling initiatives. As technology advances and new applications emerge, we can expect even greater reliance on this remarkable material in the future.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusion over other materials?

Aluminum offers a combination of lightweight properties, corrosion resistance, and versatility that other materials like steel or plastic may not provide. It also has excellent thermal conductivity and can be easily recycled.

2. How does the manufacturing process of aluminum extrusion work?

The process involves heating an aluminum billet until it's malleable, then forcing it through a die to create a specific shape. Once cooled, the extruded profile can be cut to length and finished as needed.

3. Can you customize the shapes of aluminum extrusions?

Yes! One of the significant advantages of aluminum extrusion is the ability to create custom profiles tailored to specific applications or design requirements.

4. What industries benefit most from using 3 4 aluminum extrusion?

Industries such as automotive, construction, aerospace, electronics, furniture manufacturing, renewable energy, and medical equipment all utilize 3 4 aluminum extrusion for its unique properties.

5. Is aluminum extrusion environmentally friendly?

Yes! Aluminum is highly recyclable without losing its properties. The recycling process consumes less energy compared to producing new aluminum from ore, making it an environmentally sustainable option.