Content Menu

● Understanding 40 80 Aluminum Extrusion

● Key Features of 40 80 Aluminum Extrusion

● Industries Utilizing 40 80 Aluminum Extrusion

● Benefits of Using 40 80 Aluminum Extrusion

● Applications of 40 80 Aluminum Extrusion

● Conclusion

● Related Questions

>> 1. What are the typical applications of 40 80 aluminum extrusion?

>> 2. How does the T-slot design benefit users?

>> 3. Is the 40 80 aluminum extrusion suitable for outdoor use?

>> 4. Can the dimensions of the extrusions be customized?

>> 5. What are the environmental benefits of using aluminum extrusions?

Aluminum extrusion is a manufacturing process that shapes aluminum into specific profiles for various applications. Among the many types of aluminum extrusions, the 40 80 aluminum extrusion stands out due to its versatility, strength, and ease of use. This article explores the industries that commonly utilize the 40 80 aluminum extrusion, highlighting its applications, benefits, and why it has become a preferred choice in modern manufacturing.

Understanding 40 80 Aluminum Extrusion

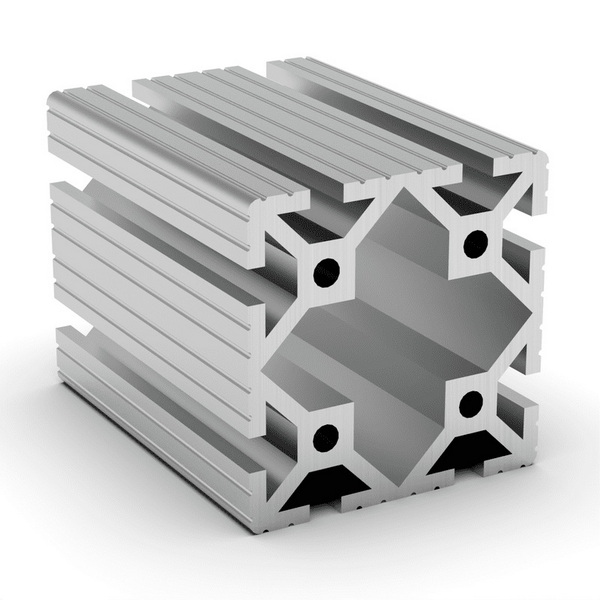

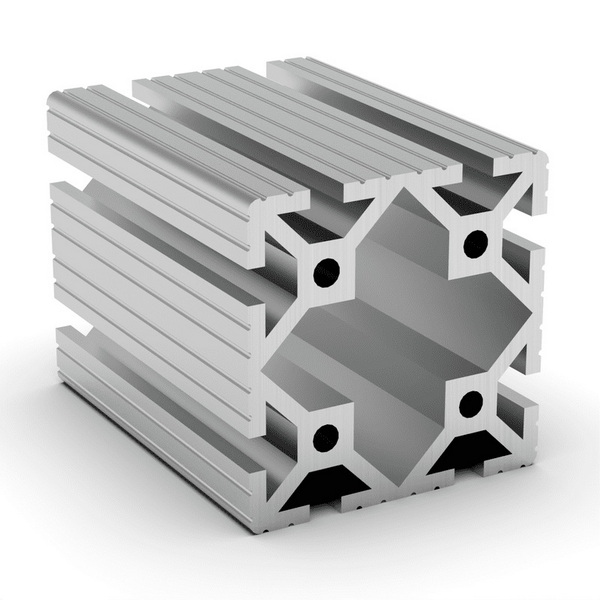

The 40 80 aluminum extrusion refers to an aluminum profile that measures 40mm by 80mm. It typically features multiple T-slots that allow for easy assembly and integration with other components. The design is robust enough to support heavy loads, making it ideal for various industrial applications.

Key Features of 40 80 Aluminum Extrusion

- Heavy-Duty Construction: The 40 80 aluminum extrusion is designed for heavy-duty applications, providing excellent stability and strength.

- T-Slot Design: The multiple T-slots facilitate easy attachment of accessories and components, allowing for flexible designs and configurations.

- Corrosion Resistance: Aluminum naturally resists corrosion, making it suitable for both indoor and outdoor applications.

- Lightweight: Despite its strength, aluminum is lightweight compared to other metals, which enhances ease of handling and transportation.

Industries Utilizing 40 80 Aluminum Extrusion

1. Manufacturing

In manufacturing, the 40 80 aluminum extrusion is widely used for constructing frames, workstations, and assembly lines. Its strength allows it to support heavy machinery and tools while maintaining stability. The modularity of this extrusion enables manufacturers to create customized solutions tailored to their specific needs, enhancing productivity and efficiency on the shop floor.

2. Automotive

The automotive industry employs the 40 80 aluminum extrusion in building jigs, fixtures, and assembly lines. Its lightweight nature helps in reducing overall vehicle weight while maintaining structural integrity. This reduction in weight can lead to improved fuel efficiency in vehicles, making it a crucial component in the push towards more sustainable automotive designs.

3. Aerospace

Aerospace manufacturers utilize this extrusion for creating lightweight structures that require high strength-to-weight ratios. Components made from 40 80 aluminum extrusion can be found in aircraft interiors and support structures. The aerospace industry often faces stringent regulations regarding weight and safety; thus, using such materials can significantly enhance performance while adhering to safety standards.

4. Robotics

Robotics companies favor the 40 80 aluminum extrusion for building robotic arms and frames due to its modularity and ease of assembly. The T-slot design allows for quick adjustments and reconfigurations as needed. This flexibility is essential in robotics, where designs may evolve rapidly based on technological advancements or specific project requirements.

5. Construction

In construction, the 40 80 aluminum extrusion is used for scaffolding systems, temporary structures, and even permanent installations due to its durability and resistance to environmental factors. Its lightweight nature makes it easier to transport and assemble on-site, reducing labor costs and time delays associated with traditional construction materials.

6. Furniture Design

Designers use the 40 80 aluminum extrusion in modern furniture design, creating sleek and functional pieces that are both aesthetically pleasing and durable. The ability to customize lengths and finishes allows furniture designers to create unique pieces that meet specific client needs while maintaining a contemporary look.

7. Electronics

The electronics industry uses this type of extrusion in manufacturing equipment racks and enclosures that require both protection and ventilation. The structural integrity provided by the 40 80 aluminum extrusion ensures that sensitive electronic components are securely housed while allowing for adequate airflow to prevent overheating.

8. Medical Equipment

Medical device manufacturers utilize the 40 80 aluminum extrusion for building frames for diagnostic machines and other medical equipment due to its cleanliness and structural properties. In environments where hygiene is paramount, such as hospitals or laboratories, using materials that are easy to clean and maintain is critical.

9. Signage

The signage industry employs this extrusion for creating durable sign frames that can withstand outdoor conditions while maintaining a professional appearance. The versatility of the 40 80 aluminum extrusion allows for creative designs that can be easily modified or expanded upon as business needs change.

10. Renewable Energy

In renewable energy sectors, particularly solar power, the 40 80 aluminum extrusion is used to construct mounting systems for solar panels, providing a strong yet lightweight solution. As the demand for renewable energy solutions grows globally, so does the need for reliable materials that can withstand various environmental conditions while supporting innovative technologies.

Benefits of Using 40 80 Aluminum Extrusion

- Cost-Effective: The modular nature of the 40 80 aluminum extrusion reduces labor costs associated with assembly while minimizing waste during production. This efficiency translates into significant savings over time for manufacturers who rely on these extrusions.

- Customization Options: Manufacturers can easily customize lengths and finishes based on specific project requirements without significant lead times. This adaptability is crucial in fast-paced industries where time-to-market can be a competitive advantage.

- Sustainability: Aluminum is recyclable, making it an environmentally friendly choice compared to other materials. As industries increasingly prioritize sustainability in their operations, using recyclable materials like aluminum becomes not just beneficial but essential.

- Aesthetic Appeal: The clean lines of the extruded profiles lend themselves well to modern design aesthetics across various industries. This visual appeal can enhance product branding and customer perception significantly.

Applications of 40 80 Aluminum Extrusion

The applications of the 40 80 aluminum extrusion are vast due to its inherent properties:

- Frame Construction: Used extensively in building frames for machinery or equipment.

- Workstations: Ideal for creating ergonomic workstations in factories or offices.

- Display Stands: Commonly used in retail environments for display stands due to its sleek appearance.

- Partition Walls: Can be employed in creating partition walls that are both functional and visually appealing.

- Transport Racks: Perfect for designing racks for transporting goods safely without adding excessive weight.

Conclusion

The versatility of the 40 80 aluminum extrusion makes it an invaluable asset across numerous industries. Its combination of strength, lightweight properties, corrosion resistance, and ease of assembly positions it as a go-to solution for manufacturers looking to innovate while maintaining efficiency. As industries continue to evolve towards more sustainable practices, the demand for such adaptable materials will likely increase.

In summary, whether it's enhancing automotive performance or providing structural integrity in aerospace applications, the significance of the 40 80 aluminum extrusion cannot be overstated. Its ability to meet diverse needs across various sectors showcases its importance in modern manufacturing processes.

Related Questions

1. What are the typical applications of 40 80 aluminum extrusion?

The typical applications include manufacturing frames, workstations, automotive jigs, aerospace components, robotics structures, furniture design, medical equipment frames, signage supports, and renewable energy mounting systems.

2. How does the T-slot design benefit users?

The T-slot design allows users to easily attach accessories or modify structures without specialized tools or hardware, enhancing flexibility in design configurations.

3. Is the 40 80 aluminum extrusion suitable for outdoor use?

Yes, due to its corrosion-resistant properties, the 40 80 aluminum extrusion is suitable for both indoor and outdoor applications.

4. Can the dimensions of the extrusions be customized?

Yes, manufacturers can customize lengths and finishes based on specific project requirements without significant lead times.

5. What are the environmental benefits of using aluminum extrusions?

Aluminum is highly recyclable and has a lower carbon footprint compared to many other materials when considering its lifecycle from production to disposal.