Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Industries Utilizing Aluminum Extruders in Ludington

>> 1. Automotive Industry

>> 2. Construction and Architecture

>> 3. Electronics Industry

>> 4. Renewable Energy

>> 5. Transportation

>> 6. Industrial Automation

>> 7. Other Commercial and Public Uses

● The Aluminum Extrusion Process

● Whitehall Industries: A Key Player in Ludington's Aluminum Extrusion Industry

● Conclusion

● FAQs

>> 1. What is aluminum extrusion?

>> 2. Which industries use aluminum extrusions?

>> 3. What are the benefits of using aluminum?

>> 4. How does the aluminum extrusion process work?

>> 5. Why is Whitehall Industries significant in Ludington?

● Citations:

Aluminum extrusion is a vital manufacturing process that plays a crucial role across various industries, particularly in Ludington, Michigan. This article explores the industries in Ludington that utilize aluminum extruders, focusing on the applications, benefits, and specific companies involved in this sector.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing heated aluminum alloy through a die to create specific shapes and profiles[2][7]. This process enables the production of complex geometries that are lightweight yet strong, making aluminum an ideal material for numerous applications[2].

Benefits of Aluminum Extrusion

- Lightweight: Aluminum has a low density, which helps reduce the overall weight of products[6].

- Strength: Despite being lightweight, aluminum exhibits excellent strength and rigidity[6].

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its durability[6].

- Versatility: The extrusion process allows for a wide range of shapes and sizes to meet diverse industry needs[1].

Industries Utilizing Aluminum Extruders in Ludington

Ludington is home to several industries that leverage aluminum extrusion for various applications:

1. Automotive Industry

The automotive sector is one of the largest consumers of aluminum extrusions[3][4]. Companies like Whitehall Industries, located in Ludington, specialize in producing precision extruded aluminum components for vehicles[1][5]. Their products include:

- Structural components[5]

- Sunroof guides

- Convertible top components

- Housings for hydraulic parts

Whitehall Industries has invested in advanced extrusion technology to meet the increasing demand for lightweight automotive parts that enhance fuel efficiency and performance[1]. The company recently ordered a HybrEx®25 extrusion press to further support this growth. Aluminum extrusions in the automotive industry are also used for engine blocks, transmission housings, panels, roof rails, and chassis[7]. The growing demand for lighter vehicles has further increased the utilization of aluminum profiles in automotive manufacturing[6].

2. Construction and Architecture

Aluminum extrusions are widely used in construction for their strength and aesthetic appeal[2][4]. In Ludington, local builders and architects utilize extruded aluminum for:

- Window frames[2]

- Door systems[2]

- Structural supports[2]

- Architectural framing[4]

- Exterior siding and roofing cladding[4]

The lightweight nature of aluminum allows for easier handling and installation while maintaining structural integrity[2]. Additionally, its corrosion resistance makes it suitable for outdoor applications[6]. Aluminum components resist distortion caused by weather and building movement, retaining strength and flexibility under loads[7].

3. Electronics Industry

The electronics sector also benefits from aluminum extrusions, particularly for heat dissipation applications[6][7]. Companies in Ludington manufacture:

- Heat sinks[5]

- Enclosures for electronic devices[5]

Aluminum's excellent thermal conductivity ensures efficient heat management, which is critical for maintaining the performance and longevity of electronic components[6][7]. Aluminum is commonly found in the heating and cooling devices of computers, audio/visual systems, and other electronics[7].

4. Renewable Energy

With the growing focus on sustainability, the renewable energy sector has started to adopt aluminum extrusions for various applications, including:

- Solar panel frames[7]

- Wind turbine components

Aluminum's lightweight properties contribute to the efficiency of renewable energy systems by reducing the overall weight of installations[6].

5. Transportation

Beyond automotive applications, aluminum extrusions are employed in other transportation sectors such as marine and rail industries[4][7]. In Ludington, companies produce:

- Boat hulls and components[7]

- Railings and structural supports for trains[7]

These applications benefit from aluminum's strength-to-weight ratio, enhancing performance while reducing energy consumption[6]. Aluminum extrusions are ideal for railway cars, marine applications, and various transportation products[4][7].

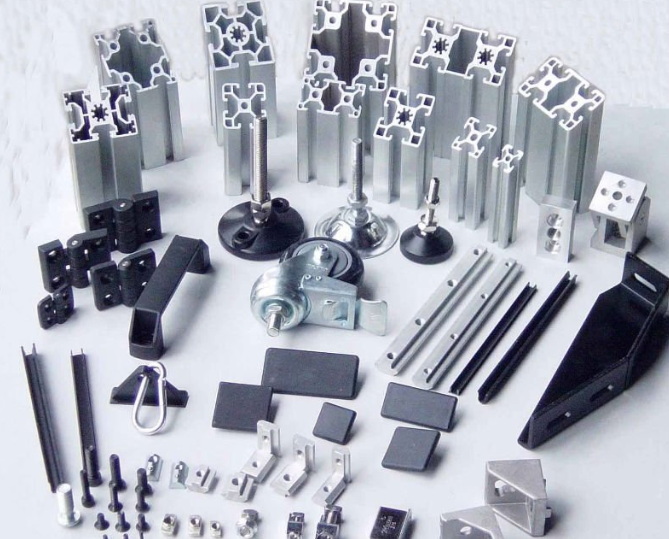

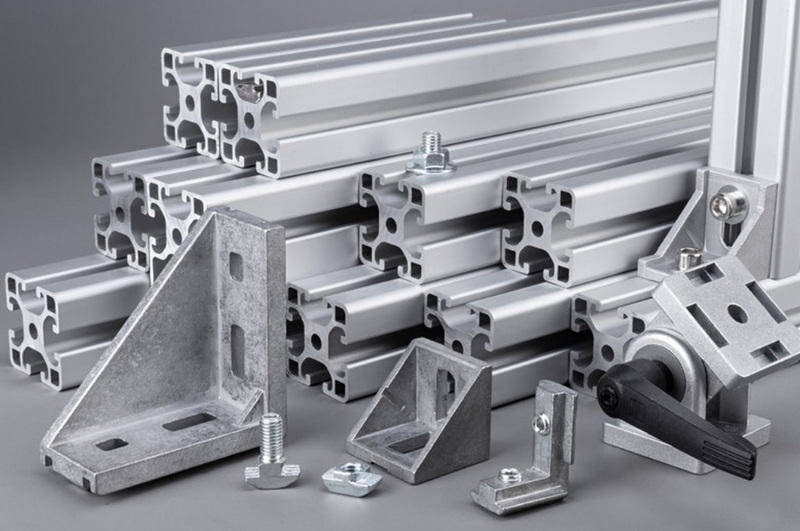

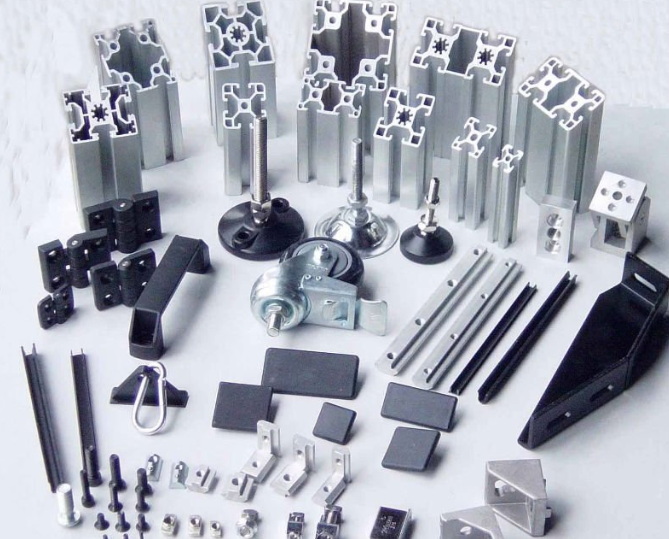

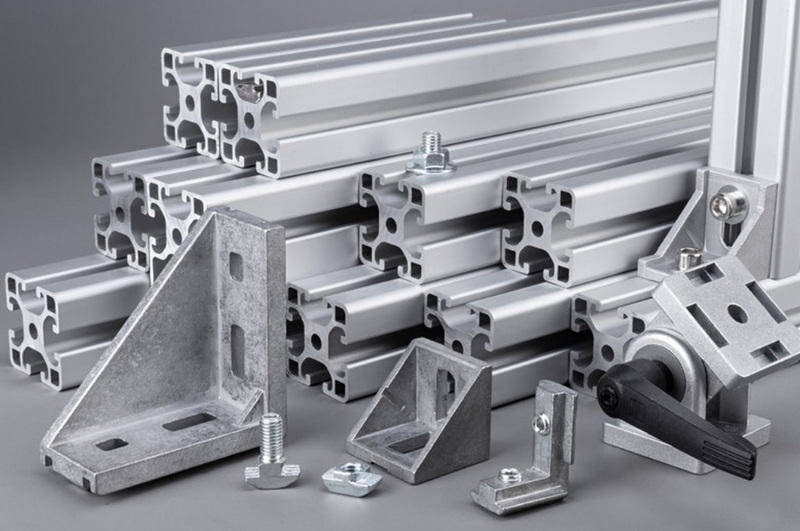

6. Industrial Automation

Industrial aluminum extrusions have become essential raw materials in the field of industrial automation[3]. Common applications include:

- Aluminum extrusion frames for supporting large-scale automation equipment[3]

- Machine guarding systems to protect equipment and operators[3]

- Equipment enclosures to protect fragile components and enhance safety[3]

- Workstations suitable for various work scenarios, such as assembly lines and anti-static environments[3]

7. Other Commercial and Public Uses

Aluminum extrusions are used in a myriad of other commercial, consumer, and public applications[4]:

- Vending machines[4]

- Circuit boards[4]

- Sports equipment (fishing poles, bicycles, tennis racquets)[4]

- Food and pharmaceutical packaging[4]

- Light bulbs[4]

The Aluminum Extrusion Process

Understanding how aluminum is extruded can provide insights into its applications[7]:

1. Billet Preparation: Aluminum billets are heated to a specific temperature to enhance malleability[7].

2. Extrusion: The heated billet is forced through a die using a hydraulic press[7].

3. Cooling: The extruded profile is cooled using air or water quenching.

4. Post-processing: This may include cutting, machining, or finishing to meet specific requirements[1]. Whitehall Industries offers precision cutting, drilling, punching, and machining services to provide complete solutions to their clients[1].

Whitehall Industries: A Key Player in Ludington's Aluminum Extrusion Industry

Whitehall Industries, located in Ludington, Michigan, stands out as a leading manufacturer of high-quality aluminum extrusions[1][5]. With over 60 years of experience, the company has established a strong reputation for providing innovative solutions and superior quality products[1]. Their commitment to quality and customer service has made them a trusted partner across various industries[5].

Whitehall Industries utilizes advanced technology and techniques to manufacture aluminum extrusions that meet the highest quality standards[1]. They offer a wide range of standard and custom extrusion profiles, working closely with clients to develop custom extrusions that meet their unique requirements[1][5]. Their aluminum extrusions are available in various finishes, including anodizing, powder coating, and painting[1].

The company's aluminum extrusions are used in a variety of applications, including automotive structural components, marine equipment, architectural framing, and industrial machinery[5]. Whitehall Industries also offers a range of value-added services, including engineering support, project management, and logistics services[1].

Whitehall Industries' commitment to quality is reflected in their ISO 9001:2015 certification, demonstrating their adherence to strict quality control standards[5]. Their state-of-the-art manufacturing facilities are equipped with the latest technology, staffed by experienced professionals dedicated to delivering excellence[5].

Conclusion

Aluminum extrusion is integral to many industries in Ludington, from automotive to construction and electronics[3][4][7]. The versatility and advantages of aluminum make it an ideal choice for manufacturers looking to innovate and improve product performance while reducing weight[6]. Companies in Ludington, such as Whitehall Industries, play a crucial role in providing high-quality aluminum extrusions and related services to meet the diverse needs of their clients[1][5]. As these companies continue to invest in advanced technologies and expand their capabilities, the future looks promising for aluminum extruders in Ludington.

FAQs

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where heated aluminum alloy is forced through a die to create specific shapes[2][7].

2. Which industries use aluminum extrusions?

Industries such as automotive, construction, electronics, renewable energy, transportation, and industrial automation utilize aluminum extrusions[3][4][7].

3. What are the benefits of using aluminum?

Aluminum is lightweight, strong, corrosion-resistant, and versatile, making it suitable for various applications[6][7].

4. How does the aluminum extrusion process work?

The process involves preparing an aluminum billet by heating it before forcing it through a die under high pressure[7].

5. Why is Whitehall Industries significant in Ludington?

Whitehall Industries specializes in producing precision extruded aluminum components and has invested heavily in advanced extrusion technology[1][5].

Citations:

[1] https://aluminum-extrusions.net/whitehall-industries-inc/

[2] http://www.zycon.com/Products/US-MI-Michigan/Aluminum-Extrusions.html

[3] https://www.linkedin.com/pulse/7-common-applications-industrial-aluminum

[4] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-michigan

[5] https://www.iqsdirectory.com/profile/whitehall-67432/

[6] https://kimsen.vn/uses-of-aluminum-extrusion-ne37.html

[7] https://www.hydro.com/profiles/uses-of-aluminum-extrusions

[8] https://www.thomasnet.com/company/uacj-automotive-whitehall-industries-10067854/profile

[9] https://www.uacj.co.jp/english/company/network/overses_affiliate.htm

[10] https://www.lightmetalage.com/news/industry-news/extrusion/uacj-acquires-aluminum-extrusion-manufacturer-whitehall-industries/

[11] https://www.scrapmonster.com/company/uacj-automotive-whitehall-industries-inc/96335

[12] https://www.linkedin.com/company/whitehall-industries

[13] https://www.zycon.com/Products/US-IL-Illinois/Custom-Aluminum-Extrusions.html

[14] https://www.alcirclebiz.com/blogs/top-aluminium-extrusion-companies-in-north-america

[15] https://www.indeed.com/q-plant-manager-aluminum-extrusion-jobs.html

[16] https://uacj-automobile.com/atz_spezial/index.html

[17] https://www.lightmetalage.com/news/industry-news/extrusion/whitehall-orders-new-extrusion-press-serve-automotive-industry/

[18] https://www.indeed.com/q-Aluminum-Extrusion-Plant-Manager-$95,000-jobs.html

[19] https://www.whitehallindustries.com/capabilities/custom-precision-aluminum-extrusion-services/

[20] https://www.scrapmonster.com/company/whitehall-industries/53682