Content Menu

● Architectural Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Automotive Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Building and Construction Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Consumer Durables Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Electrical Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Furniture Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Industrial Machinery and Equipment

>> Key Applications:

>> Benefits of Using Aluminum:

● Marine Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Medical Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● RV Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Solar Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Transportation Industry

>> Key Applications:

>> Benefits of Using Aluminum:

● Key Aluminum Extruders in Indianapolis, Indiana

● The Extrusion Process

>> Steps in the Aluminum Extrusion Process:

● Advantages of Aluminum Extrusion

● Conclusion

● FAQ About Aluminum Extruders in Indianapolis, Indiana

>> 1. What types of aluminum alloys are commonly used in extrusion?

>> 2. What finishing options are available for aluminum extrusions?

>> 3. How does the aluminum extrusion process work?

>> 4. What are the benefits of using aluminum extrusions compared to other materials?

>> 5. How can I find a reliable aluminum extruder in Indianapolis, Indiana?

● Citations:

Aluminum extruders play a crucial role in various industries in Indianapolis and throughout Indiana. These companies manufacture custom and standard aluminum profiles used in countless applications, from architectural components to automotive parts[1]. The adaptability of aluminum, combined with the precision of the extrusion process, makes it an ideal material for numerous sectors[1]. This article explores the diverse industries in Indianapolis that rely on aluminum extruders, highlighting the specific applications and benefits of using aluminum in each sector.

Architectural Industry

The architectural industry is a significant consumer of aluminum extrusions. Aluminum is used for window frames, door frames, curtain walls, and structural components[2]. Its lightweight nature, corrosion resistance, and strength make it ideal for both interior and exterior applications. In Indianapolis, many commercial and residential buildings incorporate aluminum extrusions for their aesthetic appeal and functional benefits[4].

Key Applications:

- Window and Door Frames: Aluminum frames are durable, require minimal maintenance, and can be easily customized to fit various designs.

- Curtain Walls: These non-structural outer walls are lightweight and provide excellent insulation and weather resistance.

- Structural Components: Aluminum beams, columns, and supports offer a strong yet light alternative to steel in certain building designs.

- Decorative Elements: Aluminum extrusions can be shaped into intricate designs for facades, railings, and other decorative features.

Benefits of Using Aluminum:

- Lightweight: Reduces the overall load on the building structure.

- Corrosion Resistance: Withstands harsh weather conditions, reducing maintenance costs.

- Strength: Provides structural integrity and durability.

- Design Flexibility: Can be extruded into various shapes and sizes.

- Sustainability: Aluminum is recyclable, making it an environmentally friendly choice.

Automotive Industry

The automotive industry in Indianapolis relies heavily on aluminum extrusions for various components. Aluminum's lightweight properties help improve fuel efficiency and performance[2]. Extruded aluminum parts are used in chassis components, body panels, engine parts, and interior trim[2].

Key Applications:

- Chassis Components: Aluminum frames and supports reduce the vehicle's weight, improving fuel economy.

- Body Panels: Aluminum body panels offer a balance of strength and weight savings.

- Engine Parts: Aluminum is used in engine blocks, cylinder heads, and other components due to its heat dissipation properties.

- Interior Trim: Aluminum accents and trim pieces add a touch of style and sophistication to vehicle interiors.

Benefits of Using Aluminum:

- Weight Reduction: Improves fuel efficiency and handling.

- Strength-to-Weight Ratio: Provides structural integrity without adding excess weight.

- Corrosion Resistance: Protects against rust and corrosion.

- Impact Resistance: Enhances vehicle safety.

- Recyclability: Supports sustainable manufacturing practices.

Building and Construction Industry

The building and construction industry utilizes aluminum extrusions for a wide range of applications. From structural supports to decorative elements, aluminum provides a versatile and durable solution[2]. Aluminum extruders in Indianapolis supply products for both residential and commercial construction projects[3].

Key Applications:

- Structural Supports: Beams, columns, and trusses made from aluminum provide a lightweight and strong framework.

- Roofing Systems: Aluminum roofing offers excellent weather resistance and longevity.

- Siding and Cladding: Aluminum siding protects buildings from the elements and enhances their aesthetic appeal.

- Rain Gutters and Downspouts: Aluminum drainage systems are durable and corrosion-resistant.

- Sunshades and Awnings: Aluminum provides a lightweight and adjustable shading solution.

Benefits of Using Aluminum:

- Durability: Withstands harsh weather conditions and resists corrosion.

- Lightweight: Simplifies installation and reduces structural load.

- Low Maintenance: Requires minimal upkeep, reducing long-term costs.

- Design Versatility: Can be shaped into various forms and finishes.

- Sustainability: Aluminum is recyclable and environmentally friendly.

Consumer Durables Industry

The consumer durables industry in Indianapolis incorporates aluminum extrusions into various products. Furniture, appliances, and recreational equipment often utilize aluminum for its strength, lightweight, and aesthetic appeal[2].

Key Applications:

- Furniture Frames: Aluminum frames provide a sturdy and lightweight base for chairs, tables, and other furniture items.

- Appliance Components: Aluminum is used in refrigerators, washing machines, and other appliances for its heat dissipation and corrosion resistance.

- Sporting Goods: Aluminum is used in bicycle frames, camping equipment, and other recreational gear for its strength and lightweight properties.

- Outdoor Equipment: Aluminum is used in patio furniture, grills, and other outdoor products for its weather resistance.

Benefits of Using Aluminum:

- Strength and Durability: Ensures long-lasting performance.

- Lightweight: Makes products easy to handle and transport.

- Corrosion Resistance: Protects against rust and weathering.

- Aesthetic Appeal: Provides a modern and sleek look.

- Recyclability: Supports sustainable manufacturing practices.

Electrical Industry

The electrical industry in Indianapolis uses aluminum extrusions for enclosures, heat sinks, and проводники[2]. Aluminum's excellent electrical conductivity and heat dissipation properties make it an ideal material for these applications.

Key Applications:

- Electrical Enclosures: Aluminum enclosures protect sensitive electrical equipment from environmental factors.

- Heat Sinks: Aluminum heat sinks dissipate heat from electronic components, preventing overheating.

- Conductors: Aluminum is used as a conductor in electrical cables and wiring.

- Lighting Fixtures: Aluminum housings and reflectors are used in lighting fixtures for their durability and heat resistance.

Benefits of Using Aluminum:

- Electrical Conductivity: Efficiently transmits electricity.

- Heat Dissipation: Prevents overheating of electronic components.

- Corrosion Resistance: Protects against environmental factors.

- Lightweight: Simplifies installation and handling.

- Durability: Ensures long-lasting performance.

Furniture Industry

The furniture industry in Indianapolis utilizes aluminum extrusions for frames, supports, and decorative elements[2]. Aluminum provides a lightweight, strong, and aesthetically pleasing solution for various furniture designs.

Key Applications:

- Furniture Frames: Aluminum frames provide a sturdy and lightweight base for chairs, tables, and sofas.

- Table Legs: Aluminum legs offer a modern and sleek look while providing excellent support.

- Decorative Accents: Aluminum trim and accents add a touch of sophistication to furniture designs.

- Outdoor Furniture: Aluminum is used in patio furniture for its weather resistance and durability.

Benefits of Using Aluminum:

- Lightweight: Makes furniture easy to move and rearrange.

- Strength and Durability: Ensures long-lasting performance.

- Corrosion Resistance: Protects against rust and weathering.

- Aesthetic Appeal: Provides a modern and sleek look.

- Recyclability: Supports sustainable manufacturing practices.

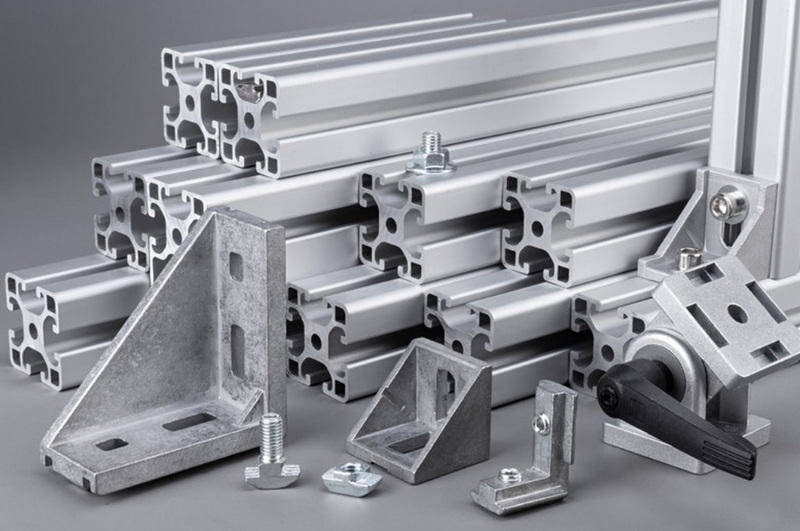

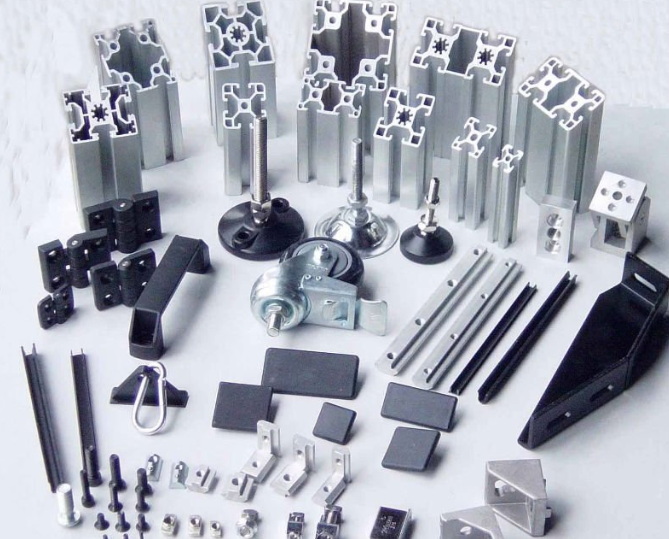

Industrial Machinery and Equipment

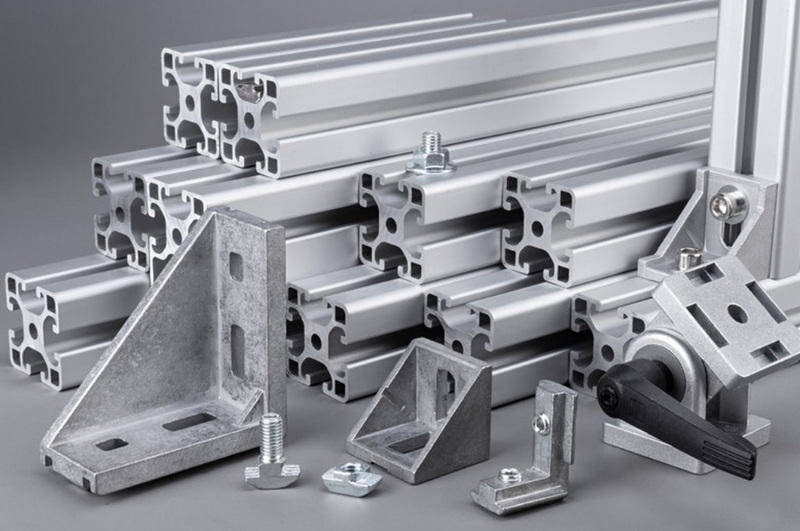

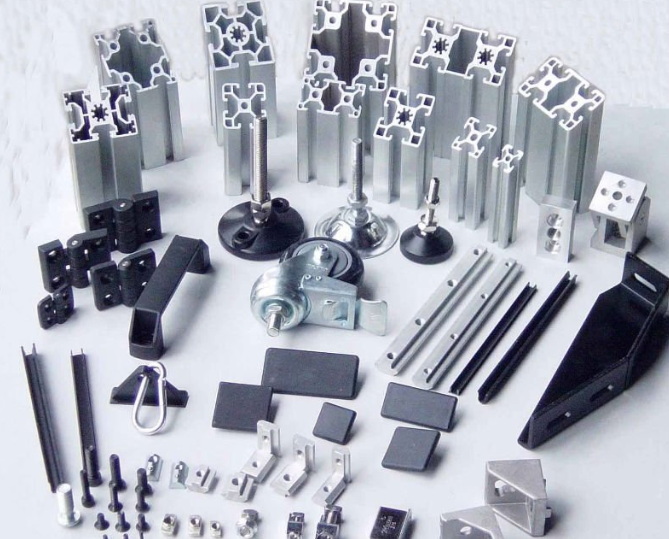

Aluminum extrusions are essential in the industrial machinery and equipment sector in Indianapolis. They are used for machine frames, safety guards, and structural components[2]. Aluminum's strength, lightweight, and corrosion resistance make it ideal for demanding industrial environments.

Key Applications:

- Machine Frames: Aluminum frames provide a sturdy and lightweight base for industrial machinery.

- Safety Guards: Aluminum guards protect workers from moving parts and hazards.

- Conveyor Systems: Aluminum is used in conveyor systems for its lightweight and corrosion resistance.

- Workstations: Aluminum frames and supports create ergonomic and efficient workstations.

Benefits of Using Aluminum:

- Strength and Durability: Ensures long-lasting performance in industrial environments.

- Lightweight: Simplifies installation and maintenance.

- Corrosion Resistance: Protects against rust and chemical exposure.

- Design Flexibility: Can be customized to fit specific machinery requirements.

- Safety: Enhances worker safety with protective guards and structures.

Marine Industry

The marine industry in Indianapolis utilizes aluminum extrusions for boat hulls, decks, and structural components[2]. Aluminum's corrosion resistance and lightweight properties are crucial for marine applications.

Key Applications:

- Boat Hulls: Aluminum hulls provide excellent corrosion resistance and reduce the overall weight of the vessel.

- Decks and Superstructures: Aluminum decks and superstructures offer a lightweight and durable solution.

- Railings and Handrails: Aluminum railings provide safety and corrosion resistance in marine environments.

- Dock Components: Aluminum is used in docks and piers for its weather resistance and structural integrity.

Benefits of Using Aluminum:

- Corrosion Resistance: Protects against saltwater and marine environments.

- Lightweight: Improves fuel efficiency and handling.

- Strength and Durability: Ensures long-lasting performance in marine conditions.

- Low Maintenance: Reduces upkeep and maintenance costs.

- Recyclability: Supports sustainable boating practices.

Medical Industry

The medical industry in Indianapolis uses aluminum extrusions for medical equipment frames, enclosures, and components[2]. Aluminum's hygienic properties, lightweight, and strength make it suitable for medical applications.

Key Applications:

- Medical Equipment Frames: Aluminum frames provide a sturdy and lightweight base for medical devices.

- Equipment Enclosures: Aluminum enclosures protect sensitive medical equipment from environmental factors.

- Surgical Instruments: Aluminum components are used in surgical instruments for their precision and lightweight properties.

- Mobility Aids: Aluminum is used in wheelchairs, walkers, and other mobility aids for its strength and lightweight.

Benefits of Using Aluminum:

- Hygienic Properties: Easy to clean and sterilize, reducing the risk of contamination.

- Lightweight: Makes equipment easy to handle and transport.

- Strength and Durability: Ensures long-lasting performance in medical environments.

- Corrosion Resistance: Protects against sterilization processes and chemicals.

- Design Flexibility: Can be customized to fit specific equipment requirements.

RV Industry

The RV industry in Indianapolis relies on aluminum extrusions for frames, siding, and structural components[2]. Aluminum's lightweight, strength, and corrosion resistance make it ideal for RV construction.

Key Applications:

- RV Frames: Aluminum frames provide a sturdy and lightweight base for RVs.

- Siding and Roofing: Aluminum siding and roofing protect RVs from the elements.

- Interior Trim: Aluminum trim and accents add a touch of style to RV interiors.

- Storage Compartments: Aluminum storage compartments provide secure and weather-resistant storage solutions.

Benefits of Using Aluminum:

- Lightweight: Improves fuel efficiency and handling.

- Strength and Durability: Ensures long-lasting performance on the road.

- Corrosion Resistance: Protects against rust and weathering.

- Low Maintenance: Reduces upkeep and maintenance costs.

- Recyclability: Supports sustainable RV manufacturing practices.

Solar Industry

The solar industry in Indianapolis uses aluminum extrusions for solar panel frames, mounting structures, and support systems[2]. Aluminum's lightweight, strength, and corrosion resistance make it ideal for solar energy applications.

Key Applications:

- Solar Panel Frames: Aluminum frames provide a sturdy and lightweight enclosure for solar panels.

- Mounting Structures: Aluminum mounting structures securely attach solar panels to roofs or ground installations.

- Support Systems: Aluminum support systems provide structural integrity for large-scale solar arrays.

- Heat Dissipation: Aluminum heat sinks dissipate heat from solar panels, improving efficiency.

Benefits of Using Aluminum:

- Lightweight: Simplifies installation and reduces structural load.

- Strength and Durability: Ensures long-lasting performance in outdoor environments.

- Corrosion Resistance: Protects against weathering and UV exposure.

- Recyclability: Supports sustainable energy practices.

- Thermal Conductivity: Improves solar panel efficiency by dissipating heat.

Transportation Industry

The broader transportation industry in Indianapolis, beyond automotive, utilizes aluminum extrusions in railways, marine applications, and aerospace[1]. Aluminum's unique properties make it suitable for various transportation needs.

Key Applications:

- Rail Cars: Aluminum is used in the construction of rail cars for its lightweight and strength.

- Marine Vessels: Aluminum is used in boat hulls and superstructures for its corrosion resistance and weight reduction.

- Aerospace Components: Aluminum is used in aircraft structures for its high strength-to-weight ratio.

- Trucking Industry: Aluminum is used in trailers and truck bodies to reduce weight and increase payload capacity.

Benefits of Using Aluminum:

- Weight Reduction: Improves fuel efficiency and reduces transportation costs.

- Strength and Durability: Ensures safe and reliable transportation.

- Corrosion Resistance: Protects against environmental factors.

- Design Flexibility: Can be customized to fit specific transportation requirements.

- Recyclability: Supports sustainable transportation practices.

Key Aluminum Extruders in Indianapolis, Indiana

Several companies in Indianapolis and the surrounding areas specialize in aluminum extrusions. These companies provide a range of services, from custom design to fabrication and finishing[1][3].

- Hydro Extrusion: With facilities in Connersville, Elkhart, and North Liberty, Hydro Extrusion offers standard and custom aluminum extrusion products throughout North America[1][3]. They provide various presses and capabilities for shaping, fabrication, and machining[1].

- Altec Aluminum Technologies: Located in Jeffersonville, Altec Aluminum Extrusions is part of a national extruder, offering services to various industries with a focus on customer service and quality[2].

- SAF Midwest: Based in Indianapolis, SAF Midwest sells aluminum sheets, extrusions, and provides architectural metal fabrication services[4].

- Postle Aluminum Co.: Headquartered in Elkhart, Postle Aluminum Co. provides aluminum extrusion, fabrication, and finishing services[5]. They offer custom dies, standard shapes, and various finishing options like anodizing and painting[5].

- Penn Aluminum International: Penn Aluminum International, founded in 1923, specializes in custom extruded shapes & drawn tubing[6].

- Nanshan America: Located in Lafayette, IN, Nanshan America specializes in large scale aluminum products[7].

The Extrusion Process

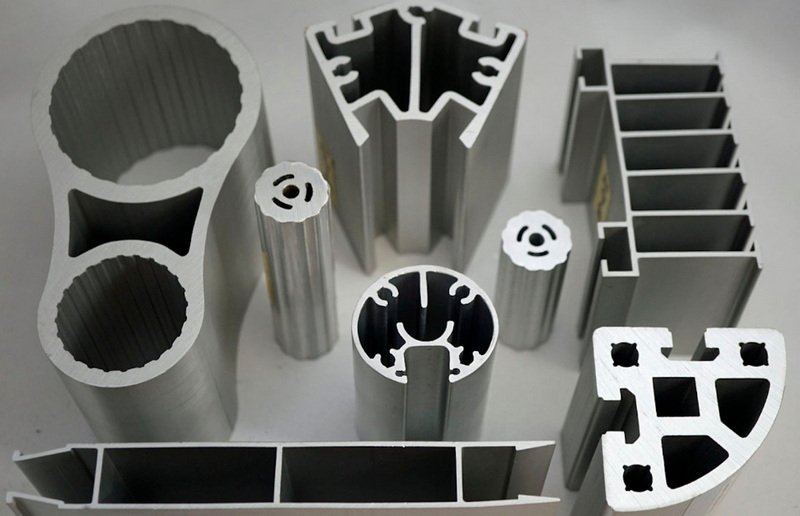

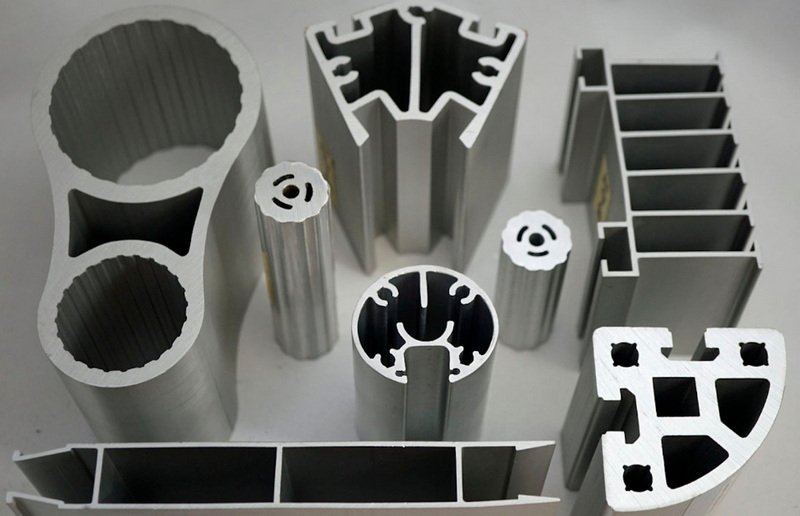

Aluminum extrusion is a process where aluminum alloy is forced through a die to create a specific shape[1]. The process begins with heating the aluminum billet to make it malleable. This heated billet is then loaded into the extrusion press, where it is pushed through the die[1]. As the aluminum emerges from the die, it takes on the shape of the die opening. The extruded profile is then cooled, stretched, and cut to the desired length[1].

Steps in the Aluminum Extrusion Process:

1. Heating the Billet: Aluminum billets are heated to a temperature that makes them pliable enough for extrusion.

2. Loading the Billet: The heated billet is loaded into the extrusion press.

3. Extrusion: The billet is forced through a die, creating the desired shape.

4. Cooling: The extruded profile is cooled to maintain its shape and structural integrity.

5. Stretching: The extruded profile is stretched to ensure it is straight and meets dimensional requirements.

6. Cutting: The extruded profile is cut to the desired length.

7. Finishing (Optional): The extruded profile may undergo additional finishing processes such as anodizing, painting, or powder coating[3].

Advantages of Aluminum Extrusion

Aluminum extrusion offers several advantages over other manufacturing processes, making it a preferred choice for many industries[1][3].

- Design Flexibility: Aluminum can be extruded into a wide variety of shapes and sizes, allowing for complex and custom designs[1].

- Cost-Effectiveness: Extrusion is a cost-effective manufacturing process, especially for high-volume production runs.

- Strength and Durability: Extruded aluminum profiles are strong and durable, making them suitable for demanding applications.

- Lightweight: Aluminum is a lightweight material, reducing the overall weight of the final product.

- Corrosion Resistance: Aluminum is naturally corrosion-resistant, making it ideal for outdoor and marine applications.

- Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice.

Conclusion

In Indianapolis, Indiana, aluminum extruders support a wide array of industries by providing essential components and materials. From architectural marvels to automotive innovations and critical medical equipment, the versatility and benefits of aluminum extrusions make them indispensable. Companies like Hydro Extrusion, Altec Aluminum Technologies, and SAF Midwest play a pivotal role in supplying these industries with high-quality aluminum products. As technology advances and industries evolve, the demand for aluminum extrusions is expected to grow, further solidifying the importance of aluminum extruders in Indianapolis and beyond.

FAQ About Aluminum Extruders in Indianapolis, Indiana

1. What types of aluminum alloys are commonly used in extrusion?

Aluminum extruders use various alloys, including 6061, 6063, and 6005A[6]. Alloy 6063 is often used for architectural applications due to its smooth surface finish and corrosion resistance. Alloy 6061 is known for its high strength and is commonly used in aerospace and automotive applications.

2. What finishing options are available for aluminum extrusions?

Aluminum extrusions can undergo various finishing processes, including anodizing, painting, powder coating, and polishing[3]. Anodizing enhances corrosion resistance and provides a decorative finish. Painting and powder coating offer a wide range of color options. Polishing creates a smooth and reflective surface.

3. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating an aluminum billet and forcing it through a die to create a specific shape[1]. The extruded profile is then cooled, stretched, and cut to the desired length. This process allows for the creation of complex and custom designs.

4. What are the benefits of using aluminum extrusions compared to other materials?

Aluminum extrusions offer several advantages, including lightweight, strength, corrosion resistance, and design flexibility[1][3]. Aluminum is also 100% recyclable, making it an environmentally friendly choice. These properties make aluminum extrusions suitable for a wide range of applications.

5. How can I find a reliable aluminum extruder in Indianapolis, Indiana?

You can find reliable aluminum extruders in Indianapolis, Indiana, by researching local manufacturers, checking online directories, and reading customer reviews[6]. Companies like Hydro Extrusion, Altec Aluminum Technologies, and SAF Midwest are well-regarded in the industry. Additionally, consider visiting trade shows and industry events to network with potential suppliers.

Citations:

[1] https://www.hydro.com/profiles/custom-aluminum-extrusions-in-indiana

[2] https://www.altecextrusions.com/about-us/

[3] https://www.hydro.com/profiles/aluminum-extrusions-manufacturer-in-indiana

[4] https://www.saf.com/saf-news/saf-midwest-opens-for-aluminum-extrusion-sheet-sales-fabrication-services/

[5] https://postledistributors.com

[6] https://www.iqsdirectory.com/aluminum-extruders/indiana/

[7] https://nanshanusa.com

[8] https://www.ziprecruiter.com/Jobs/Aluminum-Extrusion/--in-Indiana

[9] https://nanshanusa.com/custom-aluminum-extrusions/

[10] https://www.indeed.com/m/jobs?q=Aluminum+Extrusion+Operations&l=Indiana

[11] https://parco-inc.com

[12] https://www.simplyhired.com/search?q=aluminum+extrusion&l=indiana

[13] https://www.patrickmetals.com

[14] https://www.ziprecruiter.com/Jobs/Aluminum-Extrusion-Manager/--in-Indiana

[15] https://bonnellaluminum.com

[16] https://www.simplyhired.com/search/map?q=aluminum+extrusion&l=indiana&mip=%2435%2C000&from=serptopfilter

[17] https://www.mapquest.com/us/indiana/mid-america-extrusions-6063398

[18] https://www.linkedin.com/jobs/view/extrusion-press-operator-at-alexandria-industries-4129601947

[19] http://www.alexandriaindustries.com

[20] https://jooble.org/jobs-aluminum-extrusion

[21] https://www.hydro.com/en/global/about-hydro/hydro-worldwide/americas/united-states/midwest/hydro-north-liberty-in/

[22] https://aluminum-extrusions.net/american-aluminum-extrusion-company-llc/

[23] https://www.fonnovaluminium.com/top-10-aluminum-extrusion-manufacturers-in-the-united-states.html

[24] https://www.psiextrusions.com

[25] https://paramountextrusions.com

[26] https://aluminummanufacturers.org/southside-steel/

[27] https://www.minalex.com

[28] https://aluminum-extrusions.net/category/indiana/

[29] https://dajcor.com/extrusion