Content Menu

● Understanding Aluminum Extrusions

● The Importance of 45-Degree Aluminum Extrusions

● Industries That Commonly Use 45 Degree Aluminum Extrusions

>> Construction and Architecture

>> Automotive Industry

>> Aerospace Sector

>> Electronics and Electrical Engineering

>> Manufacturing and Industrial Applications

>> Furniture and Interior Design

>> Transportation and Railways

>> Renewable Energy

● Advantages of Using 45 Degree Aluminum Extrusions

>> Lightweight and Strong

>> Corrosion Resistance

>> Design Flexibility

>> Ease of Fabrication

>> Sustainability

● Conclusion

● Frequently Asked Questions

>> 1. What are the main benefits of using aluminum extrusions?

>> 2. In which industries are 45-degree aluminum extrusions commonly used?

>> 3. How does aluminum's corrosion resistance benefit its applications?

>> 4. Can aluminum extrusions be customized for specific projects?

>> 5. Is aluminum a sustainable material?

Aluminum extrusions are a vital component in various industries due to their versatility, strength, and lightweight properties. Among the different types of aluminum extrusions, the 45-degree aluminum extrusion stands out for its unique applications and benefits. This article explores the industries that commonly use 45-degree aluminum extrusions, the reasons behind their popularity, and the advantages they offer.

Understanding Aluminum Extrusions

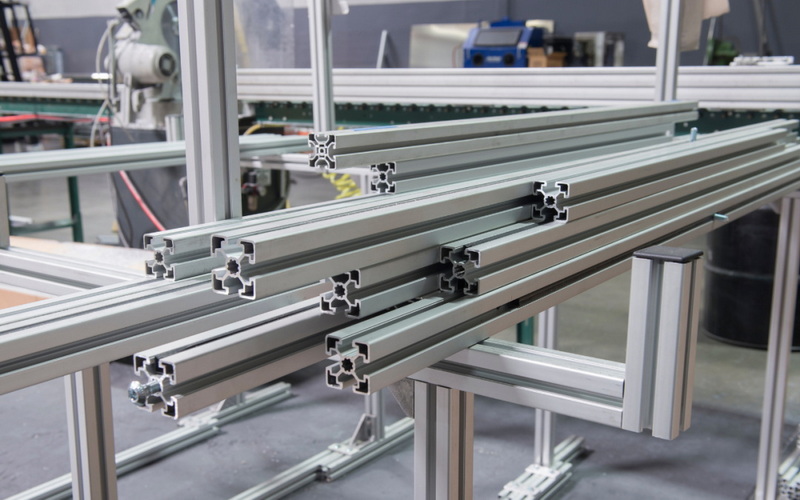

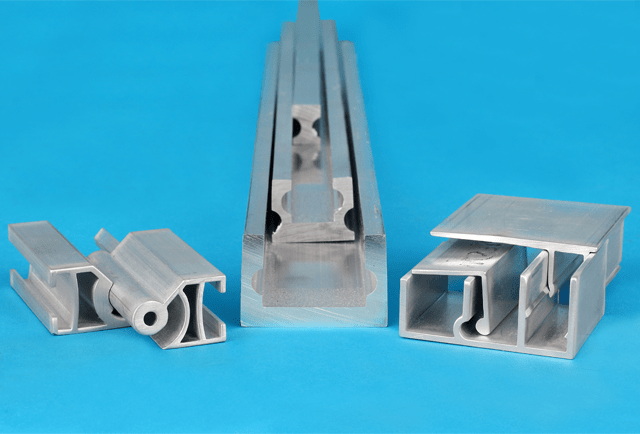

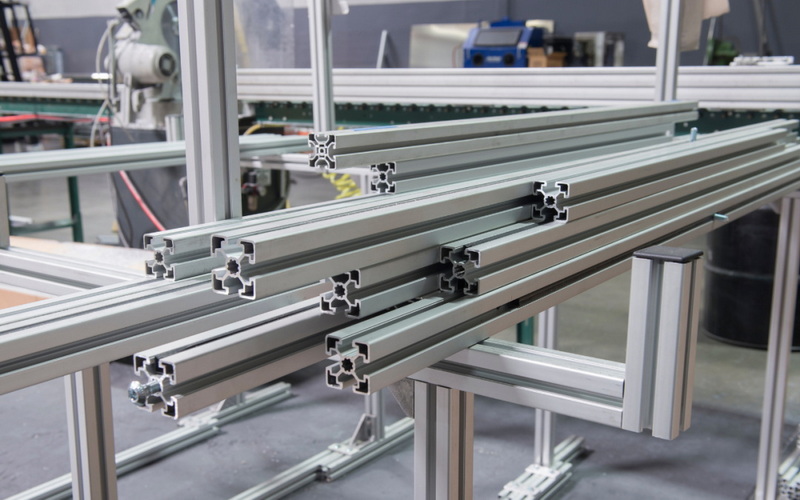

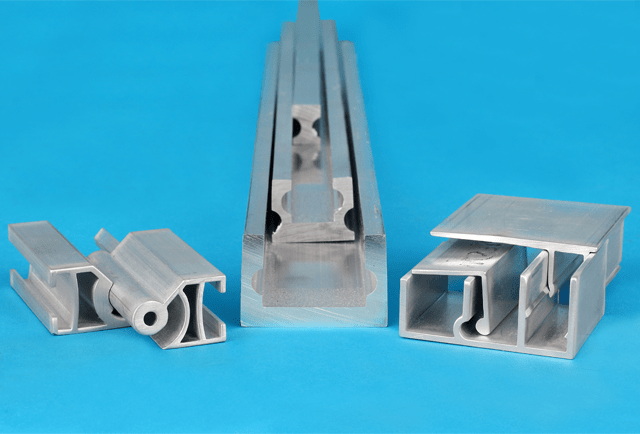

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy by forcing it through a die with a specific cross-sectional profile. This process allows for the creation of complex shapes that are lightweight yet strong, making aluminum extrusions ideal for a wide range of applications. The extrusion process can produce various profiles, including solid, hollow, and semi-hollow shapes, which can be tailored to meet specific design requirements.

The Importance of 45-Degree Aluminum Extrusions

The 45-degree aluminum extrusion is particularly useful in applications where structural integrity and aesthetic appeal are essential. Its angled design allows for seamless connections and supports various assembly configurations, making it a preferred choice in many industries. The ability to create strong joints at 45 degrees enhances the overall stability of structures, which is crucial in construction and manufacturing applications.

Industries That Commonly Use 45 Degree Aluminum Extrusions

Construction and Architecture

In the construction industry, 45-degree aluminum extrusions are widely used for framing, window and door systems, and structural supports. Their lightweight nature reduces the overall weight of structures while maintaining strength and durability. Architects and builders appreciate the aesthetic flexibility that aluminum provides, allowing for modern designs that incorporate large glass panels and open spaces. The use of aluminum also contributes to energy efficiency, as it can be designed to accommodate thermal breaks, reducing heat transfer.

Automotive Industry

The automotive industry has increasingly adopted aluminum extrusions, including 45-degree profiles, to reduce vehicle weight and improve fuel efficiency. Aluminum's corrosion resistance and strength make it an ideal material for components such as chassis, body panels, and structural reinforcements. The use of 45-degree aluminum extrusions allows for innovative designs that enhance performance while meeting safety standards. Additionally, the lightweight nature of aluminum contributes to better handling and acceleration, making vehicles more efficient.

Aerospace Sector

In aerospace applications, weight reduction is critical for improving fuel efficiency and performance. 45-degree aluminum extrusions are used in aircraft frames, support structures, and interior components. The high strength-to-weight ratio of aluminum makes it suitable for demanding aerospace environments, where safety and reliability are paramount. The aerospace industry benefits from the ability to create complex shapes that can withstand high stress and extreme conditions, ensuring the safety of passengers and cargo.

Electronics and Electrical Engineering

The electronics industry utilizes 45-degree aluminum extrusions for heat sinks, enclosures, and mounting brackets. Aluminum's excellent thermal conductivity helps dissipate heat from electronic components, ensuring optimal performance and longevity. The versatility of aluminum extrusions allows for custom designs that meet specific electronic housing requirements. Furthermore, the lightweight nature of aluminum makes it easier to integrate into portable electronic devices, enhancing their usability.

Manufacturing and Industrial Applications

In manufacturing, 45-degree aluminum extrusions are commonly used for machine frames, conveyor systems, and workstations. Their modular design allows for easy assembly and customization, making them ideal for creating efficient production lines. The lightweight nature of aluminum also reduces the strain on machinery, enhancing overall productivity. Additionally, the ability to quickly adapt and modify aluminum structures allows manufacturers to respond to changing production needs effectively.

Furniture and Interior Design

The furniture industry has embraced aluminum extrusions for creating modern and stylish furniture pieces. 45-degree aluminum profiles are used in the construction of tables, chairs, and shelving units. The sleek appearance of aluminum complements contemporary design aesthetics, making it a popular choice for both residential and commercial furniture. The durability and low maintenance of aluminum furniture also appeal to consumers looking for long-lasting solutions.

Transportation and Railways

In the transportation sector, 45-degree aluminum extrusions are utilized in the construction of train carriages, buses, and other vehicles. The lightweight properties of aluminum contribute to fuel efficiency and lower emissions. Additionally, aluminum's resistance to corrosion ensures longevity in harsh environmental conditions. The ability to create strong, lightweight structures helps improve the overall performance of transportation systems, making them more sustainable.

Renewable Energy

The renewable energy sector, particularly solar energy, uses 45-degree aluminum extrusions for mounting solar panels. The strength and durability of aluminum ensure that solar installations can withstand various weather conditions while providing reliable support for solar arrays. The lightweight nature of aluminum also facilitates easier installation and maintenance of solar energy systems, contributing to the growth of renewable energy solutions.

Advantages of Using 45 Degree Aluminum Extrusions

Lightweight and Strong

One of the primary benefits of aluminum extrusions is their lightweight nature combined with high strength. This characteristic is particularly advantageous in industries where weight reduction is crucial, such as aerospace and automotive. The ability to create strong yet lightweight components allows for innovative designs that enhance performance and efficiency.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that prevents corrosion, making it suitable for outdoor applications and environments exposed to moisture. This property enhances the longevity of products made from aluminum extrusions. The corrosion resistance of aluminum also reduces maintenance costs, as there is less need for protective coatings or treatments.

Design Flexibility

The extrusion process allows for the creation of complex shapes and profiles, providing designers with the flexibility to innovate. 45-degree aluminum extrusions can be easily integrated into various designs, accommodating specific project requirements. This design flexibility enables engineers and architects to push the boundaries of creativity while ensuring structural integrity.

Ease of Fabrication

Aluminum extrusions can be easily cut, drilled, and assembled, making them convenient for manufacturers. The ability to customize lengths and profiles further enhances their usability in different applications. This ease of fabrication allows for quicker turnaround times in production, enabling companies to meet tight deadlines and adapt to changing market demands.

Sustainability

Aluminum is a highly recyclable material, making it an environmentally friendly choice. The use of aluminum extrusions contributes to sustainable practices in various industries, reducing the overall carbon footprint. The recyclability of aluminum means that it can be reused multiple times without losing its properties, making it a sustainable option for future generations.

Conclusion

45-degree aluminum extrusions play a crucial role in numerous industries, offering a combination of strength, lightweight properties, and design flexibility. From construction and automotive to electronics and renewable energy, the applications of these extrusions are vast and varied. As industries continue to seek innovative solutions for efficiency and sustainability, the demand for aluminum extrusions, particularly at 45 degrees, is likely to grow.

Frequently Asked Questions

1. What are the main benefits of using aluminum extrusions?

Aluminum extrusions are lightweight, strong, corrosion-resistant, and offer design flexibility, making them ideal for various applications.

2. In which industries are 45-degree aluminum extrusions commonly used?

They are commonly used in construction, automotive, aerospace, electronics, manufacturing, furniture design, transportation, and renewable energy sectors.

3. How does aluminum's corrosion resistance benefit its applications?

Aluminum's natural oxide layer protects it from corrosion, ensuring longevity and reliability in outdoor and harsh environments.

4. Can aluminum extrusions be customized for specific projects?

Yes, aluminum extrusions can be easily cut, drilled, and assembled, allowing for customization to meet specific project requirements.

5. Is aluminum a sustainable material?

Yes, aluminum is highly recyclable, making it an environmentally friendly choice for various industries.