Content Menu

● Manufacturing Industry

● Automotive Industry

● Construction Industry

● Aerospace Industry

● Electronics Industry

● Renewable Energy Sector

● Furniture Industry

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusions?

>> 2. How is aluminum extrusion manufactured?

>> 3. Can aluminum extrusions be recycled?

>> 4. What industries benefit the most from aluminum extrusions?

>> 5. How do I choose the right aluminum extrusion profile for my project?

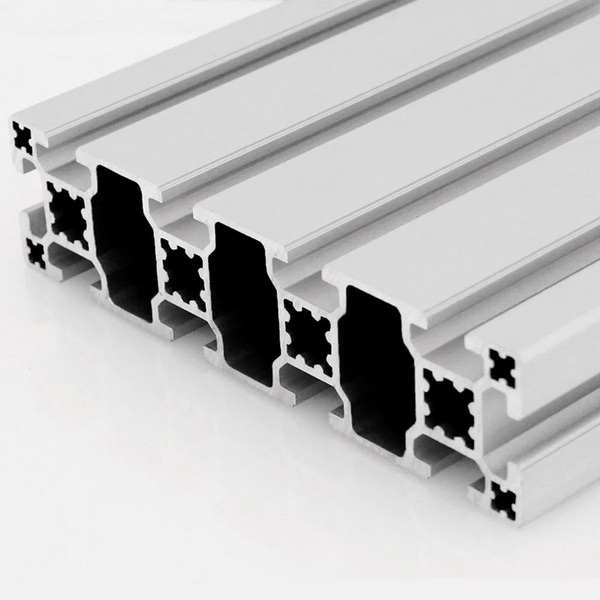

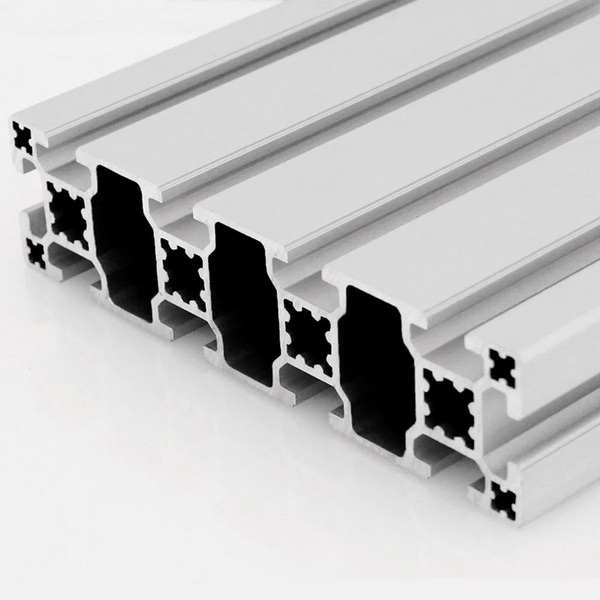

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The versatility of aluminum extrusions makes them a popular choice across various industries. Among the many sizes available, the 40x160 mm aluminum extrusion profile stands out due to its robust design and adaptability. This article explores the industries that commonly use 40x160 aluminum extrusion and the reasons behind its widespread application.

Manufacturing Industry

The manufacturing sector is one of the largest consumers of aluminum extrusions, including the 40x160 profile. This industry utilizes aluminum extrusions for various applications, such as:

- Machine Frames: The strength and lightweight nature of aluminum make it ideal for constructing machine frames. The 40x160 profile provides the necessary rigidity while keeping the overall weight manageable. This is particularly important in automated manufacturing environments where precision and stability are crucial.

- Conveyor Systems: Aluminum extrusions are commonly used in conveyor systems due to their durability and resistance to corrosion. The 40x160 profile can be easily integrated into conveyor designs, allowing for efficient material handling. Its ability to support heavy loads while maintaining structural integrity makes it a preferred choice for many manufacturers.

- Workstations: Custom workstations made from aluminum extrusions can be designed to fit specific manufacturing processes. The 40x160 profile allows for the creation of sturdy and adjustable work surfaces, enhancing productivity and ergonomics in the workplace.

Automotive Industry

The automotive industry has increasingly turned to aluminum extrusions to reduce vehicle weight and improve fuel efficiency. The 40x160 aluminum extrusion is particularly useful in this sector for several reasons:

- Structural Components: The profile is used in the construction of various structural components, such as chassis and frames. Its strength-to-weight ratio is advantageous for enhancing vehicle performance, allowing manufacturers to meet stringent fuel economy standards.

- Heat Exchangers: Aluminum's excellent thermal conductivity makes it suitable for heat exchangers. The 40x160 profile can be designed to optimize airflow and cooling efficiency in automotive applications, contributing to better engine performance and longevity.

- Interior and Exterior Trim: Aluminum extrusions are also used for aesthetic components, such as trim and moldings. The 40x160 profile can be finished in various ways to enhance the vehicle's appearance, providing both functional and decorative benefits.

Construction Industry

In the construction industry, aluminum extrusions are favored for their lightweight and corrosion-resistant properties. The 40x160 profile is commonly used in:

- Window Frames: Aluminum window frames made from the 40x160 profile offer durability and low maintenance. They can be designed to accommodate various glazing options, providing energy efficiency and aesthetic appeal.

- Curtain Walls: The profile is ideal for curtain wall systems, providing structural support while allowing for large glass panels. This enhances the aesthetic appeal of modern buildings and allows for natural light to penetrate deep into interior spaces.

- Structural Supports: The 40x160 aluminum extrusion can be used as a structural support in various applications, including roofing and facades, due to its strength and stability. Its resistance to environmental factors makes it a reliable choice for long-lasting construction.

Aerospace Industry

The aerospace industry demands materials that are lightweight yet strong, making aluminum extrusions a perfect fit. The 40x160 profile is utilized in:

- Aircraft Frames: The profile is used in the construction of aircraft frames, where weight reduction is critical for fuel efficiency and performance. The aerospace sector often requires materials that can withstand extreme conditions, and aluminum meets these demands effectively.

- Interior Components: Aluminum extrusions are also used for interior components, such as overhead bins and seat frames, providing strength without adding excessive weight. This is essential for maintaining the overall performance and safety of the aircraft.

- Support Structures: The 40x160 profile can be employed in various support structures within aircraft, ensuring safety and reliability. Its ability to be customized for specific applications makes it a versatile choice in aerospace engineering.

Electronics Industry

The electronics industry relies on aluminum extrusions for their thermal management properties and structural integrity. The 40x160 profile is commonly used in:

- Heat Sinks: Aluminum extrusions are often used to create heat sinks for electronic devices. The 40x160 profile can be designed to maximize surface area for effective heat dissipation, which is crucial for maintaining optimal operating temperatures in electronic components.

- Enclosures: The profile is suitable for constructing enclosures for electronic equipment, providing protection while allowing for efficient cooling. This is particularly important in high-performance computing applications where heat management is critical.

- Mounting Frames: The 40x160 aluminum extrusion can be used to create mounting frames for various electronic components, ensuring stability and ease of assembly. Its lightweight nature allows for easy handling and installation in complex electronic systems.

Renewable Energy Sector

The renewable energy sector, particularly solar energy, has seen a rise in the use of aluminum extrusions. The 40x160 profile is utilized in:

- Solar Panel Frames: Aluminum extrusions provide a lightweight and durable frame for solar panels, ensuring they can withstand environmental stresses. The 40x160 profile is designed to support the weight of solar panels while allowing for easy installation and maintenance.

- Mounting Systems: The profile is used in mounting systems for solar panels, allowing for easy installation and adjustment to optimize sunlight exposure. This flexibility is essential for maximizing energy capture in solar applications.

- Wind Turbine Components: The strength and lightweight nature of aluminum make it suitable for various components in wind turbines, including support structures and housings. The 40x160 profile can be adapted for use in both onshore and offshore wind energy systems.

Furniture Industry

The furniture industry has embraced aluminum extrusions for their modern aesthetic and functional properties. The 40x160 profile is commonly used in:

- Office Furniture: Aluminum extrusions are used in the construction of office desks, chairs, and partitions, providing a sleek and contemporary look. The lightweight nature of aluminum allows for easy reconfiguration of office spaces.

- Outdoor Furniture: The corrosion resistance of aluminum makes it ideal for outdoor furniture, where the 40x160 profile can be used to create durable and stylish pieces. This is particularly important for maintaining the appearance and functionality of outdoor furniture over time.

- Modular Systems: The versatility of aluminum extrusions allows for the creation of modular furniture systems that can be easily reconfigured to meet changing needs. This adaptability is a significant advantage in dynamic work environments.

Conclusion

The 40x160 aluminum extrusion profile is a versatile and widely used component across various industries. Its strength, lightweight nature, and resistance to corrosion make it an ideal choice for applications ranging from manufacturing and automotive to construction and renewable energy. As industries continue to innovate and seek efficient solutions, the demand for aluminum extrusions, particularly the 40x160 profile, is expected to grow.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusions?

Aluminum extrusions offer a lightweight, durable, and corrosion-resistant solution for various applications. They can be easily customized and are cost-effective for large-scale production.

2. How is aluminum extrusion manufactured?

The aluminum extrusion process involves heating aluminum billets until they are malleable, then forcing them through a die to create the desired shape. The extruded profiles are then cooled and cut to length.

3. Can aluminum extrusions be recycled?

Yes, aluminum extrusions are highly recyclable. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, making it an environmentally friendly option.

4. What industries benefit the most from aluminum extrusions?

Industries such as manufacturing, automotive, construction, aerospace, electronics, renewable energy, and furniture all benefit from the use of aluminum extrusions due to their versatility and performance.

5. How do I choose the right aluminum extrusion profile for my project?

When selecting an aluminum extrusion profile, consider factors such as the required strength, weight, corrosion resistance, and specific application needs. Consulting with a supplier can also provide valuable insights.