Content Menu

● Manufacturing Industry

● Automotive Industry

● Aerospace Industry

● Construction Industry

● Electronics Industry

● Robotics and Automation

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. Why is 40160 aluminum extrusion popular?

>> 3. What are the common applications of 40160 aluminum extrusion?

>> 4. How does aluminum extrusion benefit the construction industry?

>> 5. Can 40160 aluminum extrusion be customized?

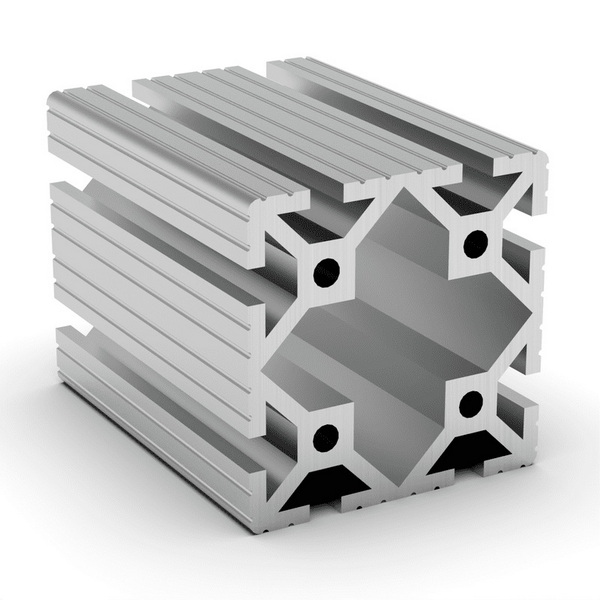

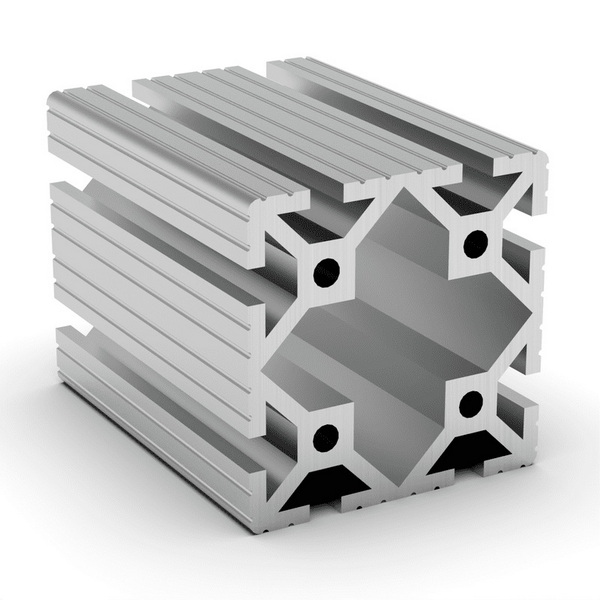

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. One of the most popular profiles is the 40160 aluminum extrusion, which measures 40mm by 160mm. This versatile profile is widely used across various industries due to its strength, lightweight properties, and adaptability. In this article, we will explore the industries that commonly use 40160 aluminum extrusion and the reasons behind its popularity.

Manufacturing Industry

The manufacturing industry is one of the largest consumers of aluminum extrusions, including the 40160 profile. This industry utilizes aluminum extrusions for various applications, such as:

- Machine Frames: The strength and rigidity of the 40160 aluminum extrusion make it an ideal choice for constructing machine frames. Its lightweight nature allows for easier handling and assembly, while its structural integrity ensures durability under heavy loads. Manufacturers can design frames that accommodate various machinery, enhancing productivity and efficiency.

- Conveyor Systems: Aluminum extrusions are commonly used in conveyor systems due to their ability to be easily customized and assembled. The 40160 profile can be used to create robust conveyor frames that can support various materials and products. This adaptability allows manufacturers to design conveyor systems that fit their specific production needs, improving workflow and reducing downtime.

- Workstations: Many manufacturing facilities use 40160 aluminum extrusion to build ergonomic workstations. The modular design allows for easy adjustments and reconfigurations, making it suitable for different tasks and workflows. This flexibility is crucial in modern manufacturing environments where efficiency and adaptability are key to success.

Automotive Industry

The automotive industry has increasingly turned to aluminum extrusions for various components due to their lightweight and strength characteristics. The 40160 aluminum extrusion is used in several applications, including:

- Chassis Components: The automotive sector uses aluminum extrusions to manufacture chassis components that require high strength-to-weight ratios. The 40160 profile can be integrated into vehicle frames, enhancing performance and fuel efficiency. By reducing the overall weight of vehicles, manufacturers can improve fuel economy and reduce emissions, aligning with global sustainability goals.

- Heat Sinks: Aluminum's excellent thermal conductivity makes it an ideal material for heat sinks in automotive applications. The 40160 extrusion can be designed to dissipate heat effectively, ensuring optimal performance of electronic components. As vehicles become more technologically advanced, the need for efficient heat management systems becomes increasingly important.

- Body Structures: Many modern vehicles incorporate aluminum extrusions in their body structures to reduce weight and improve fuel efficiency. The 40160 profile can be used in various structural applications, contributing to the overall strength and safety of the vehicle. This trend is particularly evident in electric vehicles, where weight reduction is critical for maximizing battery performance.

Aerospace Industry

The aerospace industry is another significant user of aluminum extrusions, including the 40160 profile. The lightweight and high-strength properties of aluminum make it an ideal material for various aerospace applications:

- Aircraft Frames: Aluminum extrusions are used in the construction of aircraft frames, where weight reduction is critical for fuel efficiency and performance. The 40160 profile can be utilized in various structural components, ensuring safety and reliability. The aerospace industry demands materials that can withstand extreme conditions, and aluminum's properties make it a preferred choice.

- Interior Components: The aerospace industry also uses aluminum extrusions for interior components, such as cabin frames and support structures. The 40160 profile can be customized to meet specific design requirements while maintaining structural integrity. This customization allows for innovative designs that enhance passenger comfort and safety.

- Landing Gear: The strength and durability of aluminum extrusions make them suitable for landing gear components. The 40160 profile can be used to create lightweight yet robust structures that can withstand the stresses of landing and takeoff. This application is critical for ensuring the safety and reliability of aircraft operations.

Construction Industry

The construction industry has embraced aluminum extrusions for various applications due to their durability, lightweight nature, and resistance to corrosion. The 40160 aluminum extrusion is commonly used in:

- Structural Frameworks: Aluminum extrusions are often used in the construction of structural frameworks for buildings and other structures. The 40160 profile provides the necessary strength and stability while being lightweight, making it easier to handle and install. This ease of installation can significantly reduce labor costs and construction time.

- Window and Door Frames: The 40160 aluminum extrusion is frequently used in the manufacturing of window and door frames. Its resistance to corrosion and weathering makes it an ideal choice for exterior applications, ensuring longevity and low maintenance. This durability is particularly important in regions with harsh weather conditions.

- Railings and Fencing: Aluminum extrusions are also used to create railings and fencing for commercial and residential properties. The 40160 profile can be designed to meet aesthetic and safety requirements while providing durability. The versatility of aluminum allows for a wide range of design options, enhancing the visual appeal of properties.

Electronics Industry

The electronics industry relies heavily on aluminum extrusions for various components due to their thermal conductivity and lightweight properties. The 40160 aluminum extrusion is used in:

- Heat Sinks: Aluminum extrusions are commonly used to manufacture heat sinks for electronic devices. The 40160 profile can be designed to maximize surface area, enhancing heat dissipation and ensuring optimal performance of electronic components. As electronic devices become more compact and powerful, effective heat management is essential.

- Enclosures: Many electronic devices require protective enclosures, and aluminum extrusions are often used to create these structures. The 40160 profile can be customized to fit specific designs while providing strength and durability. This customization allows manufacturers to create enclosures that meet both functional and aesthetic requirements.

- Mounting Frames: The electronics industry also uses aluminum extrusions for mounting frames that support various components. The lightweight nature of the 40160 profile allows for easy installation and adjustments. This flexibility is crucial in fast-paced environments where rapid prototyping and design changes are common.

Robotics and Automation

The rise of robotics and automation has led to increased demand for aluminum extrusions, particularly the 40160 profile. This industry utilizes aluminum extrusions for:

- Robot Frames: The lightweight and strong characteristics of aluminum make it an ideal material for constructing robot frames. The 40160 profile can be used to create robust structures that can support various robotic components. This strength is essential for ensuring the reliability and performance of robotic systems.

- Automation Equipment: Many automation systems rely on aluminum extrusions for their frameworks. The modular design of the 40160 profile allows for easy customization and reconfiguration, making it suitable for different applications. This adaptability is vital in industries where production processes are constantly evolving.

- Safety Guards: Aluminum extrusions are often used to create safety guards and enclosures for robotic systems. The 40160 profile can be designed to meet safety standards while providing visibility and accessibility. This focus on safety is critical in environments where human operators work alongside automated systems.

Conclusion

The 40160 aluminum extrusion is a versatile and widely used profile across various industries, including manufacturing, automotive, aerospace, construction, electronics, and robotics. Its lightweight nature, strength, and adaptability make it an ideal choice for numerous applications. As industries continue to innovate and seek efficient solutions, the demand for aluminum extrusions like the 40160 profile is expected to grow.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile by forcing it through a die.

2. Why is 40160 aluminum extrusion popular?

The 40160 aluminum extrusion is popular due to its strength, lightweight properties, and versatility, making it suitable for various applications across multiple industries.

3. What are the common applications of 40160 aluminum extrusion?

Common applications include machine frames, conveyor systems, workstations, automotive components, aircraft frames, and electronic enclosures.

4. How does aluminum extrusion benefit the construction industry?

Aluminum extrusion provides durability, lightweight structures, and resistance to corrosion, making it ideal for structural frameworks, window frames, and railings.

5. Can 40160 aluminum extrusion be customized?

Yes, the 40160 aluminum extrusion can be easily customized to meet specific design requirements and applications, allowing for flexibility in various industries.