Content Menu

● Understanding Aluminum Extrusions

>> Key Properties of 1.5 Aluminum Extrusions

● Industries That Commonly Use 1.5 Aluminum Extrusions

>> Construction and Architecture

>> Automotive

>> Aerospace

>> Electronics

>> Furniture

>> Transportation

>> Renewable Energy

● Benefits of Using 1.5 Aluminum Extrusions

>> Cost-Effectiveness

>> Sustainability

>> Customization

>> Aesthetic Appeal

● Conclusion

● Frequently Asked Questions

>> 1. What are the advantages of using aluminum extrusions?

>> 2. How are aluminum extrusions manufactured?

>> 3. What industries benefit the most from aluminum extrusions?

>> 4. Can aluminum extrusions be customized?

>> 5. Is aluminum environmentally friendly?

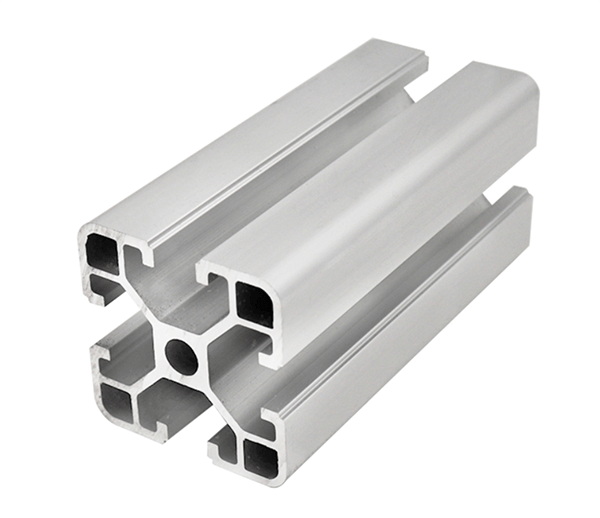

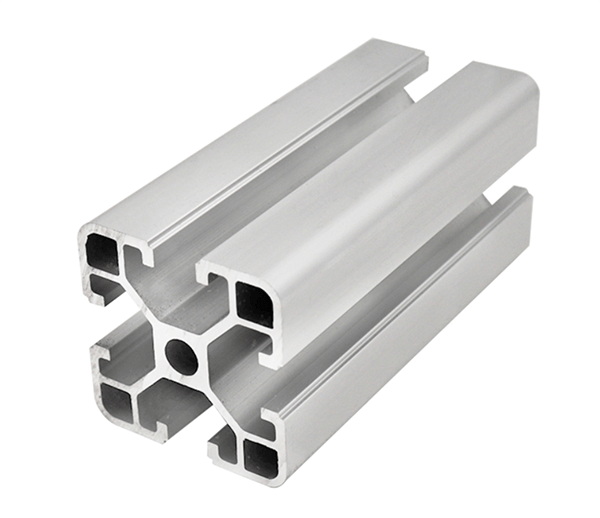

Aluminum extrusions have become a cornerstone in various industries due to their versatility, strength, and lightweight properties. Among the different sizes and profiles available, 1.5 aluminum extrusions are particularly popular. This article explores the industries that commonly utilize 1.5 aluminum extrusions, the reasons behind their widespread use, and the benefits they offer.

Understanding Aluminum Extrusions

Aluminum extrusion is a process that involves shaping aluminum alloy into a desired cross-sectional profile. This is achieved by forcing the aluminum through a die, which gives it the desired shape. The resulting extrusions can be cut to length and used in various applications. The 1.5-inch size is particularly favored for its balance between strength and weight, making it suitable for a wide range of applications.

Key Properties of 1.5 Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

3. Strength: Despite its lightweight nature, aluminum has a high strength-to-weight ratio, making it suitable for structural applications.

4. Versatility: Aluminum extrusions can be easily customized to meet specific design requirements, allowing for a wide range of applications.

Industries That Commonly Use 1.5 Aluminum Extrusions

Construction and Architecture

In the construction industry, 1.5 aluminum extrusions are widely used for window frames, door frames, and curtain walls. Their lightweight nature allows for easier installation, while their strength ensures durability. Additionally, aluminum's resistance to corrosion makes it an ideal choice for outdoor applications. The aesthetic appeal of aluminum also allows architects to create modern designs that enhance the visual appeal of buildings.

Automotive

The automotive industry has increasingly turned to aluminum extrusions to reduce vehicle weight and improve fuel efficiency. 1.5 aluminum extrusions are used in various components, including chassis, bumpers, and structural supports. The lightweight nature of aluminum helps manufacturers meet stringent fuel economy standards while maintaining safety and performance. Furthermore, the use of aluminum in vehicles contributes to better handling and acceleration, making it a preferred choice for many automotive manufacturers.

Aerospace

In aerospace applications, weight reduction is critical for performance and fuel efficiency. 1.5 aluminum extrusions are used in aircraft frames, wing structures, and other components. The high strength-to-weight ratio of aluminum makes it an ideal material for aerospace engineering, where every ounce counts. Additionally, aluminum's ability to withstand extreme temperatures and its resistance to fatigue make it suitable for various aerospace applications.

Electronics

The electronics industry utilizes 1.5 aluminum extrusions for heat sinks, enclosures, and structural components. Aluminum's excellent thermal conductivity helps dissipate heat from electronic devices, ensuring optimal performance. Additionally, the ability to customize extrusions allows manufacturers to create enclosures that meet specific design and functional requirements. The lightweight nature of aluminum also makes it easier to integrate into portable electronic devices, enhancing their usability.

Furniture

In the furniture industry, 1.5 aluminum extrusions are used to create modern and stylish designs. They are commonly found in office furniture, shelving systems, and display units. The lightweight and durable nature of aluminum allows for innovative designs that are both functional and aesthetically pleasing. Moreover, aluminum's ability to be finished in various colors and textures adds to its appeal in contemporary furniture design.

Transportation

Beyond automotive and aerospace, aluminum extrusions are used in various transportation applications, including rail and marine. 1.5 aluminum extrusions are utilized in train carriages, boat frames, and other structural components. The lightweight properties of aluminum contribute to improved fuel efficiency and performance in these applications. Additionally, the corrosion resistance of aluminum makes it suitable for marine environments, where exposure to saltwater can be detrimental to other materials.

Renewable Energy

The renewable energy sector, particularly solar energy, has embraced aluminum extrusions for mounting systems and frames. 1.5 aluminum extrusions provide the necessary strength and durability to support solar panels while being lightweight enough to facilitate installation. The use of aluminum in solar applications not only enhances the structural integrity of solar installations but also contributes to the overall sustainability of renewable energy solutions.

Benefits of Using 1.5 Aluminum Extrusions

Cost-Effectiveness

While the initial cost of aluminum may be higher than some other materials, the long-term benefits often outweigh the initial investment. Aluminum's durability and low maintenance requirements lead to cost savings over time. Additionally, the lightweight nature of aluminum can reduce shipping costs and labor expenses during installation.

Sustainability

Aluminum is a highly recyclable material, making it an environmentally friendly choice. The use of aluminum extrusions can contribute to sustainable building practices and reduce the overall carbon footprint of projects. Many manufacturers are now focusing on using recycled aluminum, which further enhances the sustainability of aluminum products.

Customization

One of the significant advantages of aluminum extrusions is the ability to customize profiles to meet specific needs. This flexibility allows designers and engineers to create unique solutions tailored to their projects. Customization can include varying lengths, shapes, and finishes, enabling a wide range of applications across different industries.

Aesthetic Appeal

Aluminum extrusions can be finished in various ways, including anodizing and powder coating, allowing for a wide range of colors and textures. This aesthetic versatility makes aluminum an attractive choice for both functional and decorative applications. The ability to create visually appealing designs without compromising on strength or durability is a significant advantage in many industries.

Conclusion

1.5 aluminum extrusions play a vital role in numerous industries, from construction and automotive to aerospace and electronics. Their lightweight, durable, and corrosion-resistant properties make them an ideal choice for a wide range of applications. As industries continue to seek innovative solutions that balance performance and sustainability, the demand for aluminum extrusions is likely to grow.

Frequently Asked Questions

1. What are the advantages of using aluminum extrusions?

Aluminum extrusions offer lightweight properties, corrosion resistance, high strength, and versatility, making them suitable for various applications.

2. How are aluminum extrusions manufactured?

Aluminum extrusions are produced by heating aluminum alloy and forcing it through a die to create a specific cross-sectional shape.

3. What industries benefit the most from aluminum extrusions?

Industries such as construction, automotive, aerospace, electronics, furniture, transportation, and renewable energy commonly use aluminum extrusions.

4. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be customized to meet specific design and functional requirements, allowing for unique solutions in various applications.

5. Is aluminum environmentally friendly?

Yes, aluminum is highly recyclable, making it an environmentally friendly choice for sustainable building practices.