Content Menu

● Understanding Aluminum Extrusion Gantries

● Industries Benefiting from Aluminum Extrusion Gantries

>> 1. Manufacturing

>> 2. Construction

>> 3. Aerospace

>> 4. Automotive

>> 5. Robotics and Automation

● Advantages of Using Aluminum Extrusion Gantries

● Visualizing Aluminum Extrusion Gantries in Action

● Case Studies Highlighting Successful Implementations

>> Case Study 1: Automotive Assembly Line

>> Case Study 2: Aerospace Component Inspection

>> Case Study 3: Construction Site Efficiency

● Future Trends in Aluminum Extrusion Gantry Applications

● Conclusion

● FAQ

>> 1. What is an aluminum extrusion gantry?

>> 2. How does aluminum compare to steel for gantry applications?

>> 3. Can aluminum extrusion gantries be customized?

>> 4. What are common applications for aluminum extrusion gantries?

>> 5. Are aluminum extrusion gantries safe to use?

● Citations:

Aluminum extrusion gantries are versatile structures that have found applications across various industries due to their unique properties. These gantries are constructed from aluminum extrusions, which provide a lightweight yet strong framework. This article explores the industries that can benefit from aluminum extrusion gantries, detailing their advantages, applications, and the specific needs they fulfill.

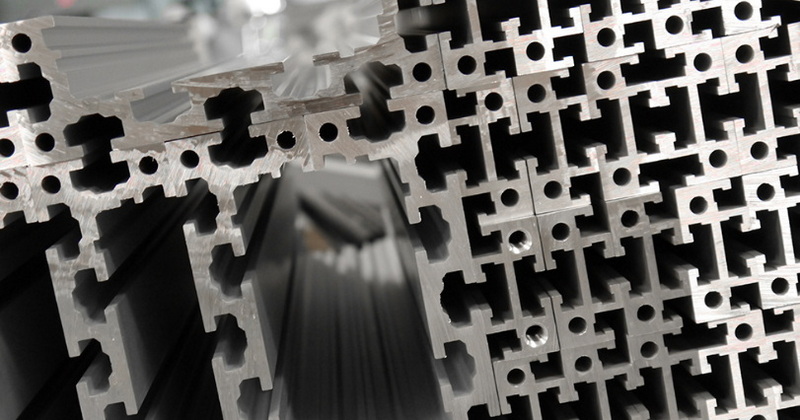

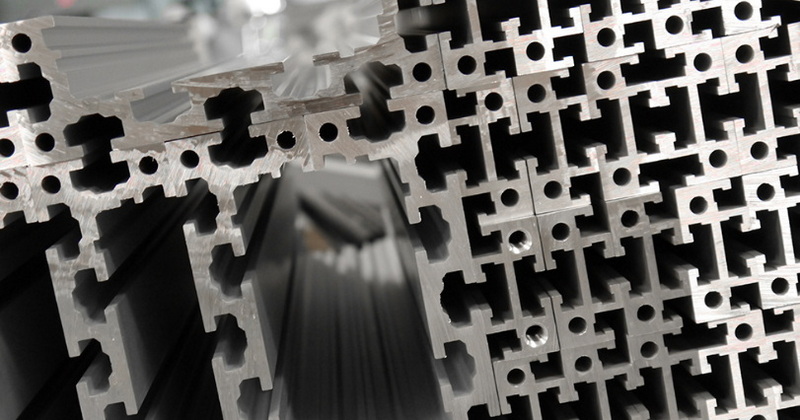

Understanding Aluminum Extrusion Gantries

Aluminum extrusion is a manufacturing process that involves shaping aluminum alloy into desired profiles by forcing it through a die. The resulting products are lightweight, corrosion-resistant, and can be designed with complex geometries. Aluminum extrusion gantries leverage these properties to create robust frameworks for various applications.

Key Benefits of Aluminum Extrusion Gantries:

- Lightweight: Aluminum is significantly lighter than steel, making it easier to transport and assemble gantries.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, enhancing its durability in various environments.

- Customizability: The extrusion process allows for the creation of custom profiles tailored to specific applications.

- Cost-Effectiveness: Lower material costs and reduced shipping expenses due to weight savings make aluminum gantries an economical choice.

Industries Benefiting from Aluminum Extrusion Gantries

1. Manufacturing

In manufacturing settings, aluminum extrusion gantries serve as support structures for machinery and equipment. They facilitate the movement of heavy components and materials within factories.

- Applications:

- Assembly Lines: Aluminum gantries provide stable support for assembly operations, allowing workers to efficiently build products with ease.

- Material Handling Systems: They are often used in conveyor systems to move materials from one point to another, reducing manual labor.

- Automated Guided Vehicles (AGVs): These structures can support AGVs, which transport materials across the factory floor without human intervention.

The flexibility of aluminum gantries allows manufacturers to adapt their production lines quickly in response to changing demands.

2. Construction

The construction industry utilizes aluminum gantries for lifting and positioning materials at job sites. Their portability and ease of assembly make them ideal for temporary structures.

- Applications:

- Lifting Heavy Building Materials: Aluminum gantries can be equipped with hoists or cranes to lift materials like steel beams or concrete panels.

- Supporting Scaffolding: They provide a stable base for scaffolding systems, ensuring safety for workers at height.

- Providing Access to Elevated Areas: Gantries can create safe walkways or platforms for workers needing access to hard-to-reach areas.

The lightweight nature of aluminum means that these structures can be easily moved around the site as needed.

3. Aerospace

In aerospace manufacturing, precision is crucial. Aluminum extrusion gantries provide stable platforms for assembly and inspection of aircraft components.

- Applications:

- Assembly Stations for Aircraft Parts: Aluminum gantries support the assembly of fuselage sections or wing components, ensuring accuracy during construction.

- Inspection Platforms: They allow inspectors to safely examine large aircraft parts from various angles, improving quality control processes.

- Tooling Support: Gantries can hold tools and equipment at convenient heights, enhancing worker ergonomics and efficiency.

The aerospace industry benefits from the strength-to-weight ratio of aluminum, which is essential when dealing with flight-critical components.

4. Automotive

The automotive industry benefits from aluminum gantries in assembly lines and testing facilities. Their lightweight nature aids in improving operational efficiency.

- Applications:

- Engine Assembly: Gantries can support heavy engine components during assembly processes, providing stability and safety.

- Vehicle Testing Rigs: They are used in testing setups where vehicles undergo various performance evaluations.

- Robotics Integration: Aluminum gantries serve as frameworks for robotic arms that perform tasks such as welding or painting on assembly lines.

The adaptability of aluminum extrusion gantries allows automotive manufacturers to streamline production processes effectively.

5. Robotics and Automation

Aluminum extrusion gantries are integral in robotics applications, providing a framework for robotic arms and automated systems.

- Applications:

- CNC Machines: These machines require stable frameworks for precision cutting and milling operations; aluminum gantries provide that stability.

- Robotic Assembly Lines: They support robotic systems that automate repetitive tasks, increasing productivity while minimizing human error.

- Material Handling Robots: Gantries facilitate the movement of goods within warehouses or factories by supporting automated systems designed for logistics.

As industries continue to embrace automation, the demand for reliable frameworks like aluminum extrusion gantries will only increase.

Advantages of Using Aluminum Extrusion Gantries

The advantages of aluminum extrusion gantries extend beyond their physical properties:

- Flexibility: They can be easily reconfigured or expanded based on project needs. This adaptability is crucial in fast-paced environments where requirements can change rapidly.

- Ease of Assembly: Quick assembly times reduce downtime on projects. Many designs do not require specialized tools, allowing teams to set up quickly and efficiently.

- Safety: Their lightweight design minimizes the risk of injury during setup and operation while providing stable support for equipment and materials. Safety features such as locking mechanisms can also be integrated into the design.

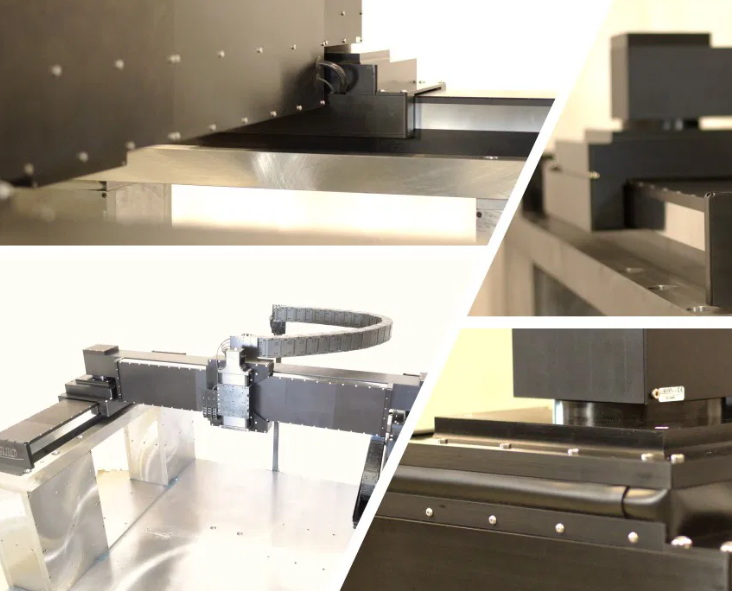

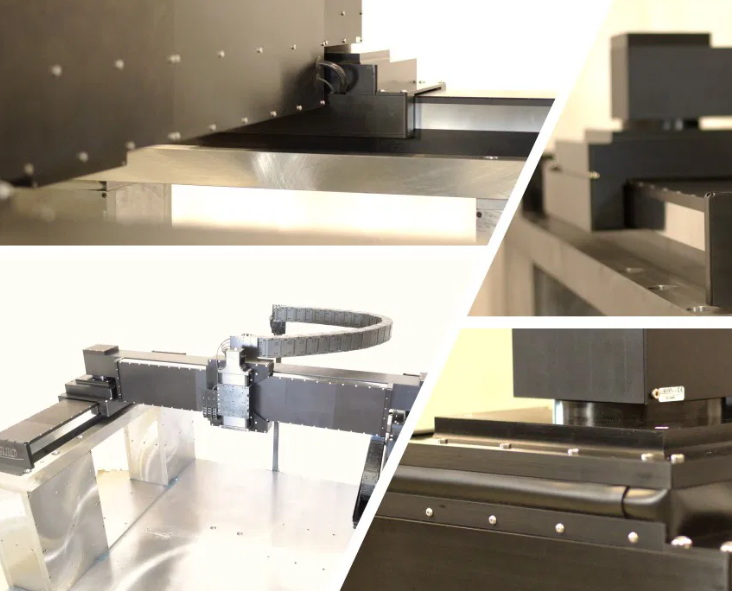

Visualizing Aluminum Extrusion Gantries in Action

To better understand the application of aluminum extrusion gantries across industries, consider the following visual representations:

Aluminum Gantry Crane in Manufacturing

Aluminum Gantry in Construction

Robotic Arm Mounted on Aluminum Gantry

Case Studies Highlighting Successful Implementations

Case Study 1: Automotive Assembly Line

An automotive manufacturer implemented aluminum extrusion gantries in their engine assembly line. By replacing heavier steel structures with lightweight aluminum options, they reduced setup time by 30% and improved worker ergonomics. The flexibility allowed them to adjust the layout easily as production demands changed.

Case Study 2: Aerospace Component Inspection

A leading aerospace company adopted aluminum extrusions for their component inspection stations. The lightweight nature allowed inspectors to maneuver easily around large parts while maintaining stability. This change led to a significant reduction in inspection times without compromising quality.

Case Study 3: Construction Site Efficiency

On a major construction project, an engineering firm utilized aluminum gantries to lift heavy materials into place. The ease of transport meant that they could reposition the structures as needed throughout different phases of construction without extensive downtime or labor costs.

Future Trends in Aluminum Extrusion Gantry Applications

As technology advances, several trends may shape the future use of aluminum extrusion gantries:

- Increased Automation: With more industries adopting automation technologies, the demand for robust support structures will grow alongside advancements in robotics.

- Sustainability Focus: As companies strive for greener practices, aluminum's recyclability will become an attractive feature for businesses looking to reduce their environmental impact.

- Smart Manufacturing Integration: The integration of IoT devices within manufacturing processes may lead to more sophisticated uses of aluminum extrusion gantries as they become part of interconnected systems designed for efficiency and data collection.

Conclusion

Aluminum extrusion gantries are invaluable across various industries due to their lightweight, durable, and customizable nature. From manufacturing to aerospace, these structures enhance efficiency and safety in operations. As industries continue to evolve towards automation and efficiency, the demand for aluminum extrusion gantries is expected to grow significantly.

FAQ

1. What is an aluminum extrusion gantry?

An aluminum extrusion gantry is a structural framework made from aluminum extrusions designed to support equipment or facilitate movement within various industrial applications.

2. How does aluminum compare to steel for gantry applications?

Aluminum is lighter than steel, making it easier to handle and transport. It also offers better corrosion resistance, which can be advantageous in certain environments.

3. Can aluminum extrusion gantries be customized?

Yes, the extrusion process allows for the creation of custom profiles tailored to specific application needs, enhancing versatility.

4. What are common applications for aluminum extrusion gantries?

Common applications include assembly lines, construction sites, aerospace manufacturing stations, automotive testing rigs, and robotics integration.

5. Are aluminum extrusion gantries safe to use?

Yes, their lightweight design reduces the risk of injury during setup and operation while providing stable support for equipment and materials.

Citations:

[1] https://www.tensilemillcnc.com/blog/12-major-benefits-of-aluminum-extrusions

[2] https://www.industrialprofile.com/t-slot-aluminum-extrusion-the-building-blocks-of-modern-manufacturing/

[3] https://www.unisontek.com.tw

[4] https://genesis.farm.bot/v1.2/Extras/bom/extrusions.html

[5] https://www.youtube.com/watch?v=wLxB1Sq0WQ8

[6] https://www.reddit.com/r/hobbycnc/comments/142xxqo/which_gantry_rail_design/

[7] https://www.spanco.com/blog/what-can-aluminum-do-for-you/

[8] https://aec.org/features-benefits

[9] https://www.alibaba.com/showroom/aluminium-gantry.html