Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Key Features to Look for in an Aluminum Extruder

>> 1. Build Quality and Material

>> 2. Extrusion Capacity

>> 3. Heating System

>> 4. Ease of Use

>> 5. Maintenance Requirements

>> 6. Price and Warranty

● Expanding on Key Features

>> Build Quality and Material

>> Extrusion Capacity

>> Heating System

>> Ease of Use

>> Maintenance Requirements

>> Price and Warranty

● Considerations

>> 1. Customer Reviews

>> 2. Brand Reputation

>> 3. Availability of Accessories

● Conclusion

● FAQ

>> 1. What is an aluminum extruder amazon used for?

>> 2. How do I maintain my aluminum extruder amazon?

>> 3. What types of dies are available for aluminum extruder amazon?

>> 4. Can I use different types of aluminum alloys in my aluminum extruder amazon?

>> 5. What safety features should I look for in an aluminum extruder amazon?

When searching for an aluminum extruder on Amazon, it's vital to consider several key features that will determine the quality and efficiency of the machine. This article delves into the essential aspects you should look for, ensuring you make an informed purchase. We will explore various features, specifications, and additional considerations to help you select the right aluminum extruder amazon for your needs.

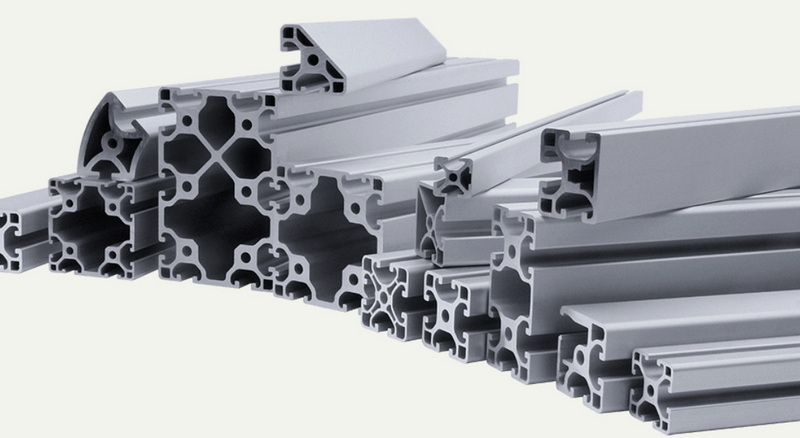

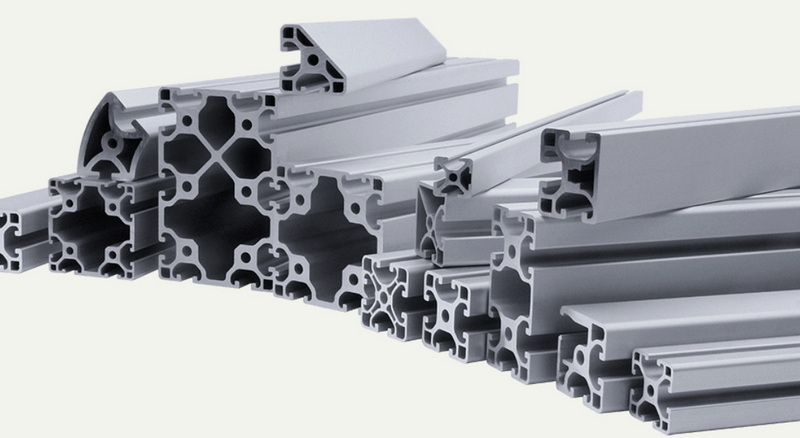

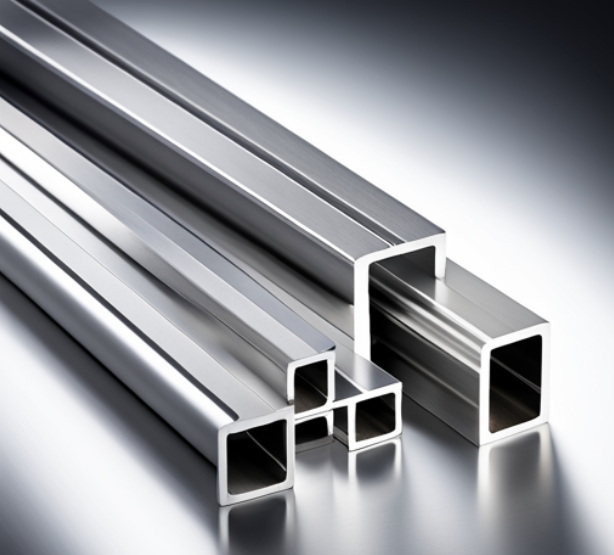

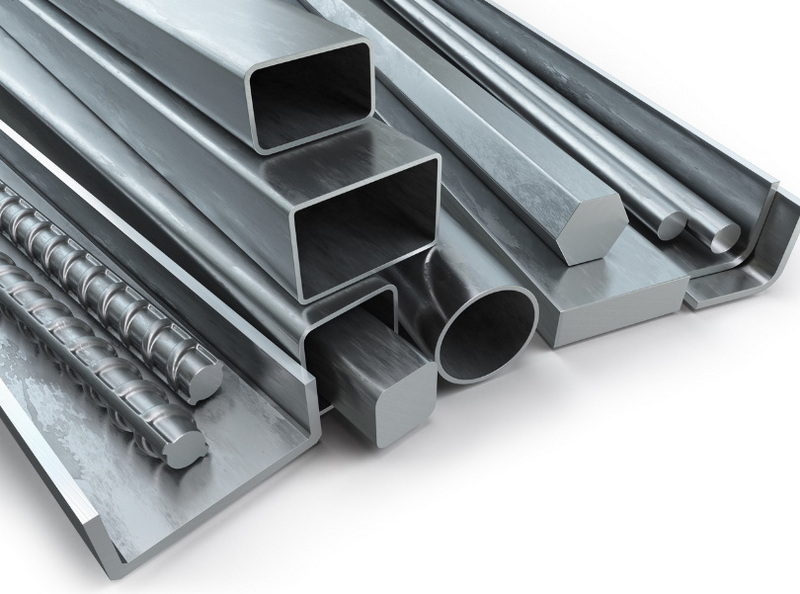

Understanding Aluminum Extrusion

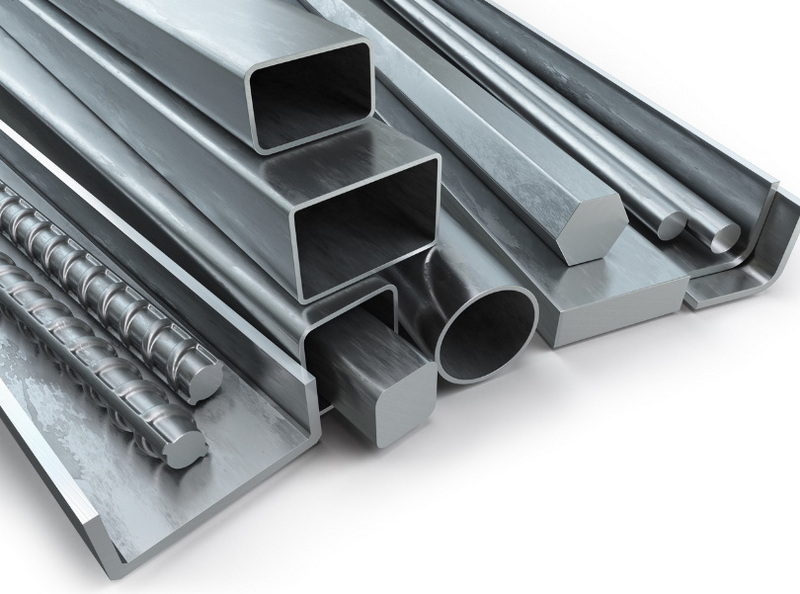

Aluminum extrusion is a process that involves shaping aluminum alloy by forcing it through a die. This method allows manufacturers to create complex cross-sectional shapes with high precision. The resulting products are used in various applications, from automotive parts to architectural elements.

Benefits of Aluminum Extrusion

- Lightweight: Aluminum is significantly lighter than steel, making it ideal for applications where weight reduction is essential.

- Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

- Versatility: The extrusion process allows for a wide range of shapes and sizes, catering to different industries.

- Cost-Effective: Compared to other metals, aluminum can be more economical due to its recyclability and lower energy consumption during production.

Key Features to Look for in an Aluminum Extruder

When evaluating aluminum extruder amazon, consider the following features:

1. Build Quality and Material

The durability of an aluminum extruder largely depends on its construction materials. Look for:

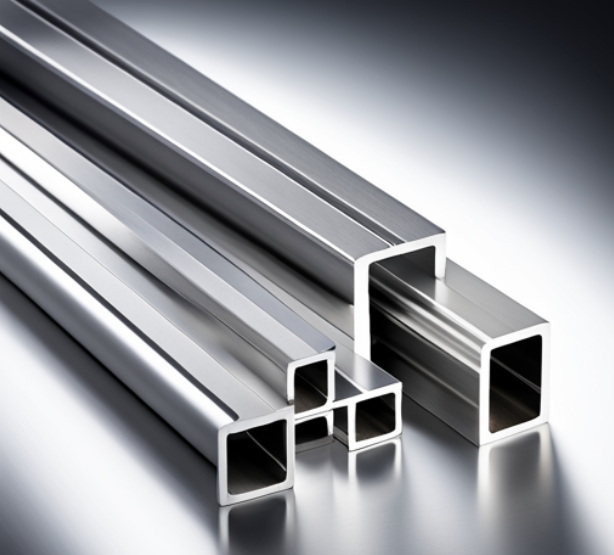

- High-Grade Aluminum: Ensure the aluminum extruder amazon is made from high-quality aluminum alloys that can withstand high pressures. The grade of aluminum used can significantly impact the lifespan and reliability of the machine. Common alloys include 6061 and 6063, known for their strength and corrosion resistance.

- Reinforced Frame: A sturdy frame reduces vibrations and enhances precision during operation. A robust frame also ensures the machine can handle the stresses of continuous operation without deformation or failure. Look for frames made from heavy-gauge steel or reinforced aluminum.

2. Extrusion Capacity

Extrusion capacity refers to the volume of material the machine can process within a specific time frame. Consider:

- Tonnage Rating: Higher tonnage ratings indicate the ability to extrude thicker materials or larger volumes. The tonnage rating reflects the maximum force the extruder can exert, influencing the size and complexity of the shapes it can produce.

- Die Size Compatibility: Ensure the aluminum extruder amazon can accommodate various die sizes for flexibility in production. Different dies allow you to create a wide range of profiles, from simple bars to intricate custom designs.

3. Heating System

The heating system is crucial for softening aluminum billets before extrusion. Look for:

- Efficient Heating Elements: A reliable heating system ensures consistent temperatures, leading to better extrusion quality. Efficient heating elements reduce energy consumption and ensure uniform heating throughout the billet.

- Temperature Control Features: Advanced models come with digital temperature controls for precise adjustments. Precise temperature control is essential for achieving optimal material flow and surface finish. Look for PID (Proportional-Integral-Derivative) controllers for accurate temperature regulation.

4. Ease of Use

User-friendly features can significantly enhance your experience with an aluminum extruder amazon:

- Intuitive Controls: Look for machines with easy-to-navigate control panels. Intuitive controls reduce the learning curve and minimize errors during operation.

- Safety Features: Ensure the machine has safety guards and emergency stop buttons to protect operators. Safety features are paramount to prevent accidents and injuries in the workplace.

5. Maintenance Requirements

Regular maintenance is essential for the longevity of your aluminum extruder amazon. Consider:

- Access to Components: Machines designed with easy access points simplify cleaning and maintenance tasks. Easy access to internal components reduces downtime and facilitates routine inspections.

- Manufacturer Support: Check if the manufacturer provides support or has readily available replacement parts. Reliable manufacturer support ensures you can quickly resolve any issues and keep your machine running smoothly.

6. Price and Warranty

Price can vary significantly among aluminum extruder amazon. Evaluate:

- Value for Money: Compare features against pricing to ensure you're getting good value. Consider the long-term costs, including energy consumption, maintenance, and potential repairs.

- Warranty Terms: A longer warranty period often reflects confidence in product durability. Read the warranty terms carefully to understand what is covered and what is not.

Expanding on Key Features

To further elaborate on each key feature:

Build Quality and Material

The build quality directly influences the operational lifespan of the aluminum extruder amazon. Machines crafted from inferior materials are prone to wear and tear, leading to frequent breakdowns and costly repairs.

- Material Strength: High-strength aluminum alloys like 7075 can provide superior durability compared to lower-grade options. Ensure the machine's frame and critical components are made from materials capable of withstanding high stress.

- Precision Machining: Precision machining ensures tight tolerances and accurate alignment of components. This reduces friction, minimizes wear, and enhances overall performance.

Extrusion Capacity

Understanding the specific needs of your application is essential when determining the required extrusion capacity.

- Production Volume: Consider your daily or weekly production targets. A higher-capacity machine is necessary for large-scale operations.

- Profile Complexity: Intricate profiles require more force and precision. Ensure the aluminum extruder amazon you choose has sufficient tonnage and control capabilities.

Heating System

The heating system plays a critical role in achieving optimal material flow during extrusion.

- Heating Zones: Multiple heating zones allow for precise temperature control along the length of the billet. This ensures uniform softening and reduces the risk of defects.

- Insulation: Proper insulation minimizes heat loss and improves energy efficiency. This can significantly reduce operating costs over time.

Ease of Use

User-friendly features can significantly improve productivity and reduce operator fatigue.

- Automated Functions: Automated functions like billet loading and profile cutting can streamline the extrusion process.

- Ergonomic Design: An ergonomically designed control panel and operating area can enhance operator comfort and reduce strain.

Maintenance Requirements

Regular maintenance is essential for preventing breakdowns and extending the lifespan of your aluminum extruder amazon.

- Lubrication System: An automated lubrication system can ensure consistent lubrication of critical components.

- Filter Replacement: Regular filter replacement is necessary to maintain the cleanliness of hydraulic fluids and prevent damage to hydraulic components.

Price and Warranty

Consider the total cost of ownership when evaluating the price of an aluminum extruder amazon.

- Energy Consumption: High-efficiency machines can significantly reduce energy costs over time.

- Maintenance Costs: Factor in the cost of routine maintenance, repairs, and replacement parts.

- Warranty Coverage: A comprehensive warranty can provide peace of mind and protect against unexpected expenses.

Considerations

1. Customer Reviews

Reading customer reviews can provide insights into real-world performance and reliability. Look for feedback on:

- Performance consistency

- Ease of setup and operation

- Customer service experiences

2. Brand Reputation

Consider purchasing from reputable brands known for producing high-quality aluminum extruder amazon. Established brands often have better support systems and product reliability.

3. Availability of Accessories

Check if the manufacturer offers additional accessories or dies that can enhance the functionality of your extruder.

Conclusion

Choosing the right aluminum extruder amazon requires careful consideration of several key features, including build quality, extrusion capacity, heating systems, ease of use, maintenance requirements, price, and warranty terms. By focusing on these aspects, you can ensure that you select a machine that meets your production needs while providing durability and efficiency.

FAQ

1. What is an aluminum extruder amazon used for?

An aluminum extruder amazon is used to shape aluminum alloys into specific profiles by forcing heated billets through a die.

2. How do I maintain my aluminum extruder amazon?

Regularly clean components, check heating elements, lubricate moving parts, and follow manufacturer guidelines for maintenance schedules.

3. What types of dies are available for aluminum extruder amazon?

There are various dies available depending on the desired profile shape, including standard shapes like angles and channels as well as custom designs.

4. Can I use different types of aluminum alloys in my aluminum extruder amazon?

Yes, many extruders can handle various aluminum alloys; however, ensure compatibility with your specific machine model.

5. What safety features should I look for in an aluminum extruder amazon?

Look for safety guards, emergency stop buttons, and thermal cutoffs to prevent overheating during operation.