Content Menu

● 1. User-Friendly Interface

>> Importance of Usability

● 2. Advanced CAD Capabilities

>> Benefits of 3D Modeling

● 3. Custom Profile Creation

>> Enhancing Design Flexibility

● 4. Prototyping and Testing Features

>> Advantages of Digital Prototyping

● 5. Collaboration Tools

>> Enhancing Team Communication

● 6. Cost Estimation and BOM Generation

>> Importance of Cost Management

● 7. Support and Training Resources

>> Building User Competence

● 8. Compatibility with Other Software

>> Streamlining Workflows

● 9. Performance Metrics and Reporting Tools

>> Leveraging Data for Improvement

● Conclusion

● FAQ

>> 1. What is aluminum extrusion design software?

>> 2. How does CAD integration benefit aluminum extrusion design?

>> 3. Can I create custom profiles using aluminum extrusion design software?

>> 4. What are simulation tools used for in aluminum extrusion design?

>> 5. Why is collaboration important in aluminum extrusion projects?

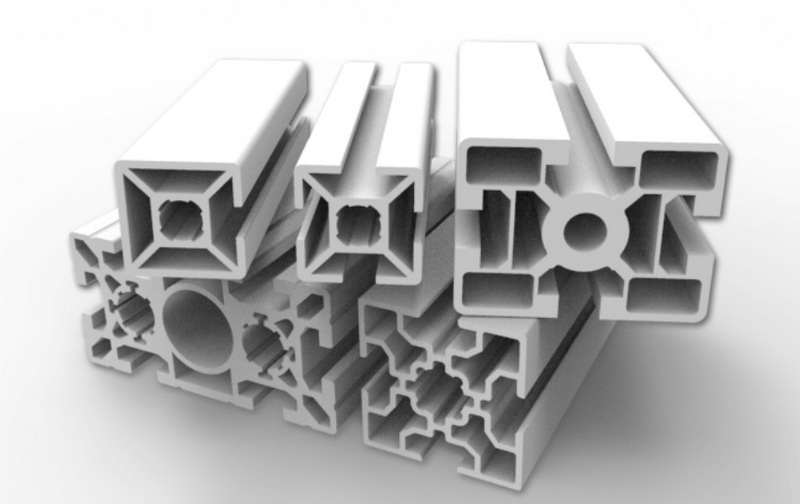

Aluminum extrusion design software plays a crucial role in the manufacturing and engineering sectors, allowing designers to create precise, intricate designs for various applications. When selecting the right software, it is essential to consider several features that enhance usability, efficiency, and output quality. This article explores the key features to look for in aluminum extrusion design software, providing insights and guidance for engineers and designers alike.

1. User-Friendly Interface

A user-friendly interface is paramount for any design software. Look for software that offers:

- Intuitive Navigation: Easy-to-understand menus and toolbars that allow users to navigate without extensive training.

- Drag-and-Drop Functionality: This feature simplifies the design process by allowing users to easily manipulate components within their designs.

- Customizable Workspace: The ability to tailor the workspace according to personal preferences can significantly enhance productivity.

Importance of Usability

Usability is a critical factor in software selection because it directly affects how quickly and effectively users can complete their tasks. A well-designed interface reduces the learning curve, enabling new users to become proficient more quickly. Additionally, intuitive navigation minimizes errors during the design process, which can save time and resources in the long run.

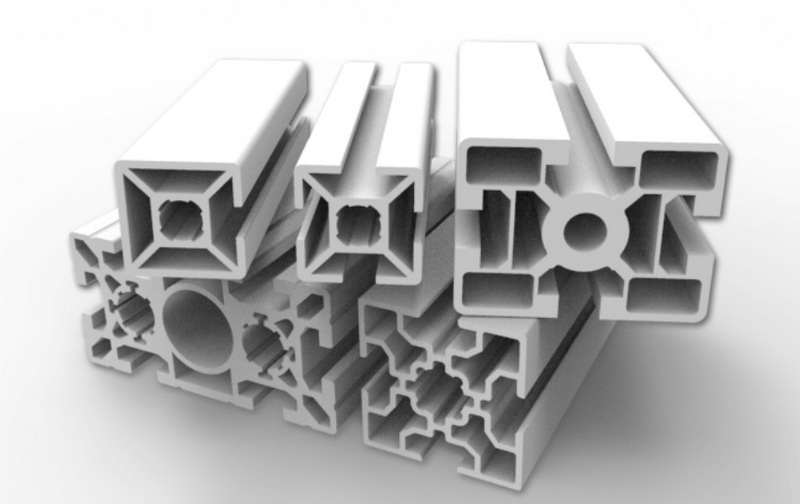

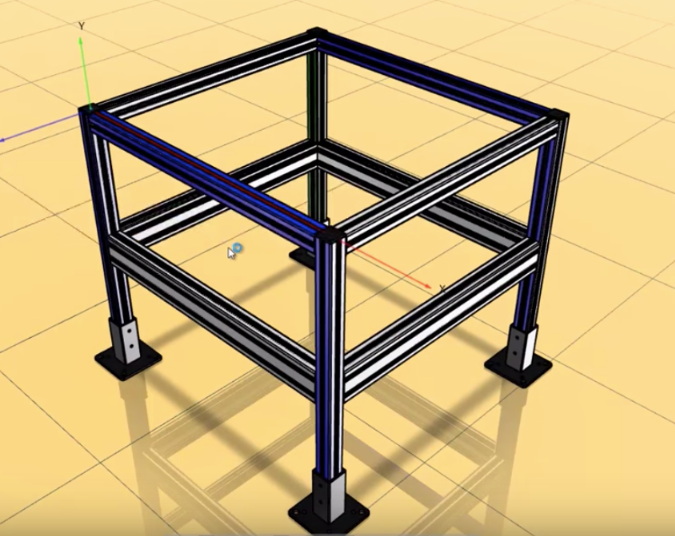

2. Advanced CAD Capabilities

Computer-Aided Design (CAD) capabilities are essential in aluminum extrusion design software. Key aspects include:

- 3D Modeling: The ability to create three-dimensional models helps visualize the final product and identify potential issues early in the design phase.

- Simulation Tools: Advanced simulation features allow users to test designs under various conditions, such as stress or thermal analysis, ensuring reliability before production.

- Integration with CAM: Look for software that integrates seamlessly with Computer-Aided Manufacturing (CAM) systems to streamline the transition from design to manufacturing.

Benefits of 3D Modeling

3D modeling is particularly beneficial in aluminum extrusion design because it allows designers to see how different components fit together in a virtual environment. This capability not only aids in visualizing complex designs but also facilitates better communication among team members and stakeholders who may not be familiar with technical drawings.

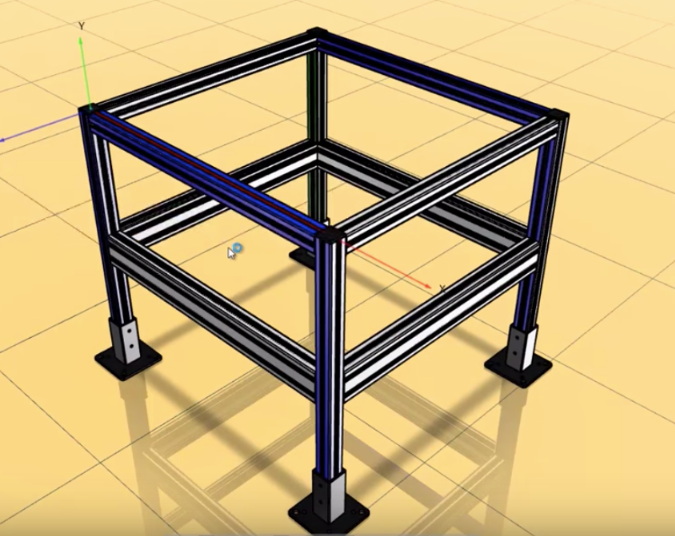

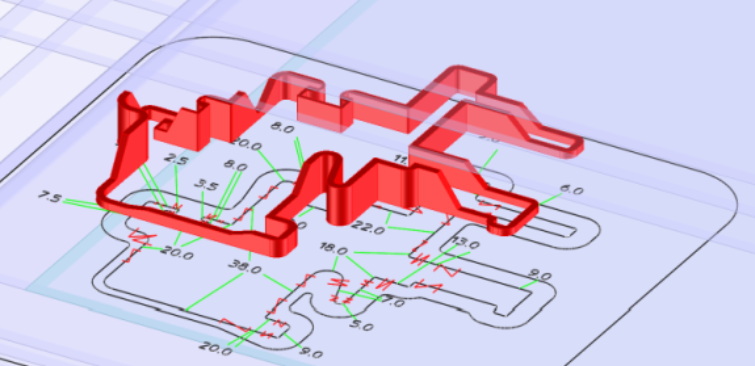

3. Custom Profile Creation

The flexibility to create custom profiles is a significant advantage in aluminum extrusion design software. Features should include:

- Profile Libraries: Access to a library of standard profiles can speed up the design process.

- Custom Profile Design Tools: Users should be able to create unique profiles tailored to specific project requirements without limitations.

- Easy Modification Options: The ability to modify existing profiles or create new ones quickly is essential for iterative design processes.

Enhancing Design Flexibility

Custom profile creation allows designers to tailor their products precisely to client specifications or project needs. This flexibility can lead to innovative designs that stand out in competitive markets. Moreover, having an extensive library of standard profiles can accelerate project timelines by reducing the need for starting from scratch on common shapes.

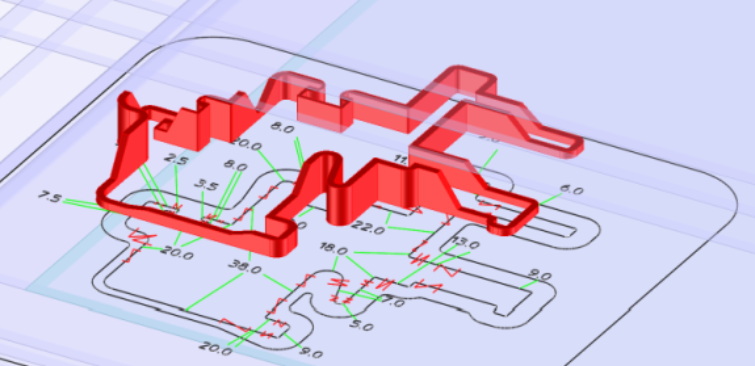

4. Prototyping and Testing Features

Efficient prototyping capabilities can save time and resources. Key features include:

- Digital Prototyping: The ability to create digital prototypes allows designers to visualize and test their designs before physical production.

- Testing Simulations: Integrated testing tools can simulate real-world conditions, helping identify potential flaws early in the design process.

Advantages of Digital Prototyping

Digital prototyping eliminates many of the costs associated with physical prototyping by allowing designers to experiment with different configurations without committing materials or time to physical models. This capability not only speeds up the development process but also enables rapid iterations based on testing feedback.

5. Collaboration Tools

Collaboration features are vital, especially in team environments. Look for:

- Cloud-Based Solutions: Cloud integration allows multiple users to access and work on designs simultaneously from different locations.

- Version Control: This feature helps track changes made by different team members, ensuring everyone is working on the latest version of a project.

- Commenting and Annotation Tools: These tools facilitate communication among team members by allowing them to leave notes or suggestions directly on the design files.

Enhancing Team Communication

Effective collaboration tools foster better communication among team members, which is crucial for successful project outcomes. By enabling real-time feedback and discussions directly within the design environment, teams can address issues promptly and make informed decisions faster.

6. Cost Estimation and BOM Generation

Cost management is crucial in any project. Effective aluminum extrusion design software should offer:

- Automatic Bill of Materials (BOM) Generation: This feature automatically compiles a list of materials needed for production, saving time during the ordering process.

- Cost Estimation Tools: Integrated cost estimation tools help predict project costs based on materials and labor, aiding in budget management.

Importance of Cost Management

Accurate cost estimation is vital for maintaining profitability in manufacturing projects. By providing tools that allow designers to calculate costs early in the design phase, companies can make informed decisions about material choices and production methods that align with budget constraints.

7. Support and Training Resources

Having access to support and training resources can significantly enhance user experience. Consider:

- Comprehensive Documentation: Detailed manuals or online help resources can assist users in navigating complex features.

- Tutorials and Webinars: Access to tutorials or live training sessions can accelerate the learning curve for new users.

- Customer Support Services: Responsive customer support is critical for resolving issues quickly and efficiently.

Building User Competence

Robust support resources empower users by providing them with the knowledge they need to utilize all features effectively. This not only enhances user satisfaction but also maximizes the return on investment in software tools by ensuring that teams can leverage their full capabilities.

8. Compatibility with Other Software

Compatibility with other software tools can enhance workflow efficiency. Key considerations include:

- File Format Support: Ensure the software supports various file formats (e.g., STEP, IGES) for easy import/export with other CAD systems.

- Integration with Other Tools: Check if the software integrates well with other engineering tools used in your workflow, such as project management or analysis software.

Streamlining Workflows

Compatibility with other systems is essential for maintaining an efficient workflow across different stages of product development. When aluminum extrusion design software can easily exchange data with other tools used by engineering teams, it reduces redundancy and minimizes errors associated with manual data transfer.

9. Performance Metrics and Reporting Tools

Performance metrics are crucial for evaluating design effectiveness over time. Look for:

- Real-Time Analytics: The ability to analyze performance data as designs are created helps identify areas for improvement immediately.

- Reporting Tools: Comprehensive reporting capabilities enable teams to generate insights about their designs' efficiency, cost-effectiveness, and potential issues based on historical data.

Leveraging Data for Improvement

Utilizing performance metrics allows organizations to learn from past projects, leading to continuous improvement in both design processes and final products. By analyzing trends over time, teams can make informed decisions that enhance productivity and reduce waste.

Conclusion

Choosing the right aluminum extrusion design software involves careful consideration of various features that enhance usability, efficiency, collaboration, and overall productivity. By focusing on user-friendly interfaces, advanced CAD capabilities, custom profile creation, prototyping tools, collaboration features, cost estimation tools, support resources, compatibility with other software systems, and performance metrics, designers can significantly improve their workflow and output quality. Investing time in selecting appropriate software will ultimately lead to better designs, reduced costs, increased productivity in aluminum extrusion projects, and a competitive edge in the market.

FAQ

1. What is aluminum extrusion design software?

Aluminum extrusion design software is a specialized tool that allows engineers and designers to create detailed designs for aluminum extrusions, including custom profiles and complex geometries.

2. How does CAD integration benefit aluminum extrusion design?

CAD integration streamlines the design process by allowing designers to create 3D models, simulate real-world conditions, and directly transfer designs into manufacturing systems without needing manual intervention.

3. Can I create custom profiles using aluminum extrusion design software?

Yes, most modern aluminum extrusion design software includes features that allow users to create custom profiles tailored specifically to their project requirements.

4. What are simulation tools used for in aluminum extrusion design?

Simulation tools help test designs under various conditions (e.g., stress testing) before production begins, ensuring reliability and identifying potential issues early in the process.

5. Why is collaboration important in aluminum extrusion projects?

Collaboration allows multiple team members to work on designs simultaneously, improving efficiency and ensuring that all stakeholders can contribute their expertise throughout the design process.