Content Menu

● Introduction

● The Aluminum Extrusion Process

>> Key Steps in Manufacturing

>> Types of Aluminum Alloys Used

● Benefits of Aluminum Extrusion

>> Lightweight and Strength Advantages

>> Design Flexibility and Customization Options

>> Cost-Effectiveness in Production

● Applications of Aluminum Extrusion

>> Construction

>> Automotive

>> Electronics

>> Aerospace

>> Furniture

● Custom Aluminum Extrusions

>> Importance of Customization in Design

>> Case Studies of Successful Custom Extrusion Projects

● Techniques in Aluminum Extrusion Manufacturing

>> Advanced Manufacturing Techniques

>> Innovations in Extrusion Technology

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusions in product design?

>> 2. How does the aluminum extrusion process work?

>> 3. What industries commonly use aluminum extrusions?

>> 4. Can aluminum extrusions be customized?

>> 5. What are some recent innovations in aluminum extrusion technology?

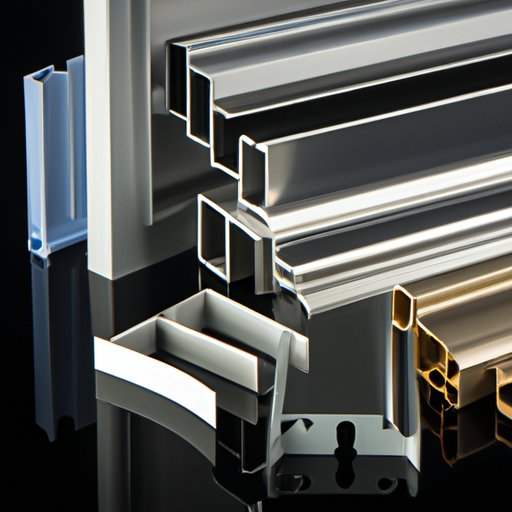

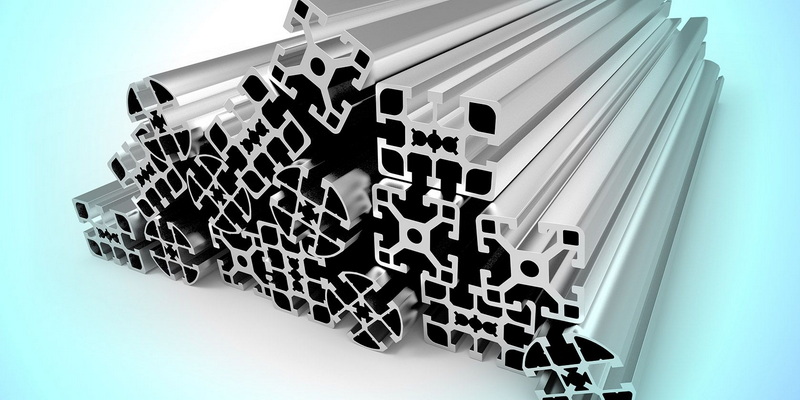

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This technique is widely used in various industries due to its versatility, lightweight nature, and strength. Custom aluminum extrusions can significantly enhance product design by providing tailored solutions that meet specific requirements. In this article, we will explore the aluminum extrusion process, its benefits, applications, and how custom extrusions can elevate your product design.

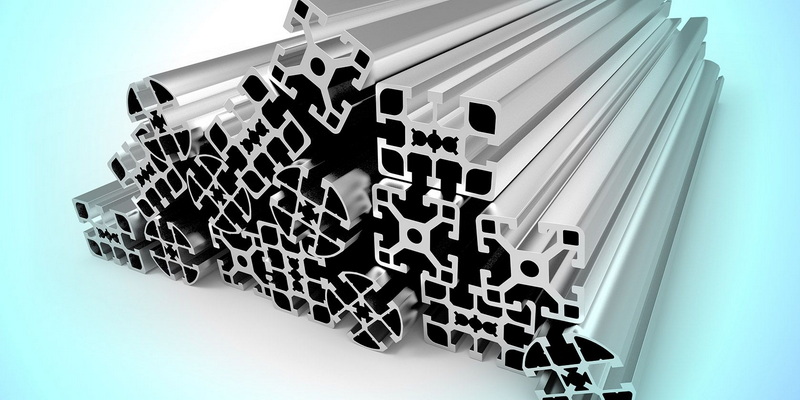

The Aluminum Extrusion Process

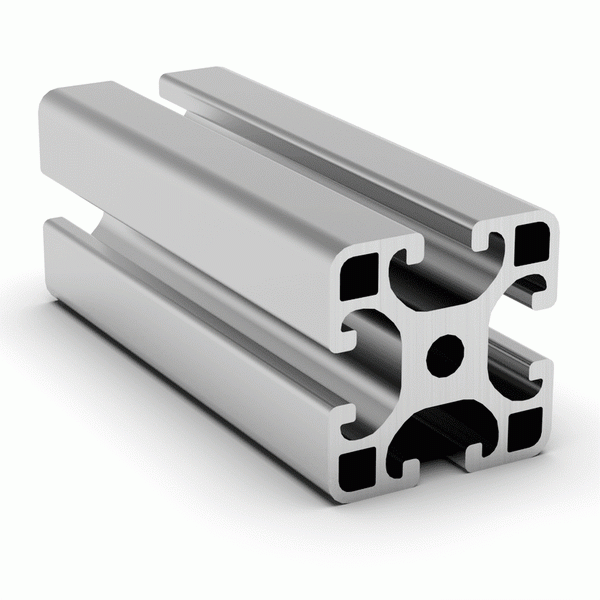

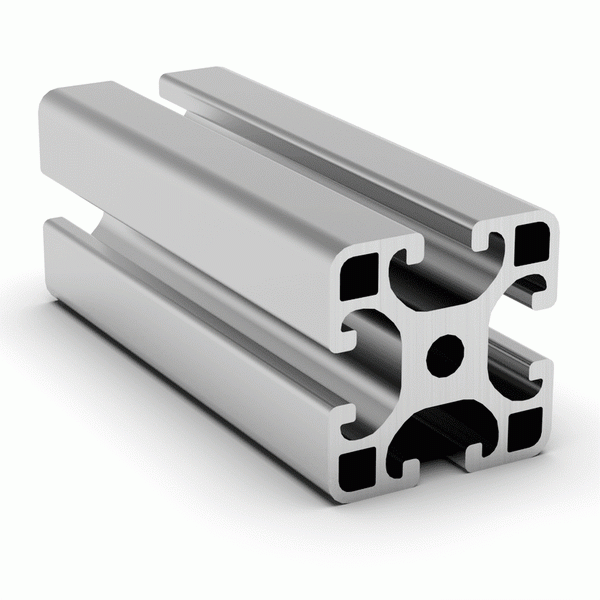

The aluminum extrusion process involves several key steps that transform raw aluminum into finished products. Initially, aluminum billets are heated to a specific temperature, making them malleable. The heated billets are then forced through a die, which shapes the aluminum into the desired profile. This process can create a wide variety of shapes, from simple to complex designs.

Key Steps in Manufacturing

1. Heating the Billet: The aluminum billet is heated to a temperature between 350°C and 500°C, depending on the alloy used. This heating process is crucial as it allows the aluminum to flow easily through the die.

2. Extrusion: Once heated, the billet is placed in an extrusion press. A ram pushes the billet through the die, creating the desired shape. The extrusion can be done in various ways, including direct and indirect extrusion.

3. Cooling: After extrusion, the newly formed aluminum profile is cooled, typically using air or water. This cooling process solidifies the aluminum and maintains its shape.

4. Cutting and Finishing: The extruded aluminum is cut to the required lengths and may undergo additional finishing processes, such as anodizing or powder coating, to enhance its appearance and corrosion resistance.

Types of Aluminum Alloys Used

Different aluminum alloys are used in the extrusion process, each offering unique properties. Common alloys include:

- 6000 Series: Known for its good corrosion resistance and weldability, making it ideal for structural applications.

- 7000 Series: Offers high strength and is often used in aerospace applications.

- 1000 Series: Known for its excellent corrosion resistance and electrical conductivity, suitable for electrical applications.

Benefits of Aluminum Extrusion

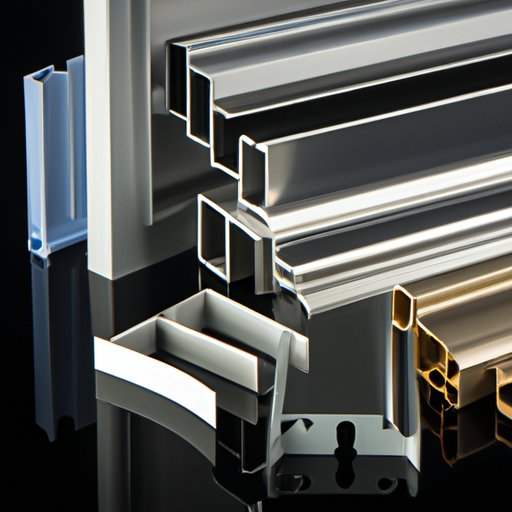

Custom aluminum extrusions provide numerous benefits that can enhance product design. Here are some of the key advantages:

Lightweight and Strength Advantages

Aluminum is known for its lightweight properties, making it an ideal choice for applications where weight reduction is crucial. Despite its lightness, aluminum also offers high strength-to-weight ratios, allowing for durable products without adding unnecessary weight.

Design Flexibility and Customization Options

One of the most significant advantages of aluminum extrusion is the design flexibility it offers. Manufacturers can create complex shapes and profiles tailored to specific applications. This customization allows designers to innovate and create unique products that stand out in the market.

Cost-Effectiveness in Production

Aluminum extrusion is a cost-effective manufacturing process, especially for large production runs. The ability to create multiple profiles from a single die reduces material waste and lowers production costs. Additionally, the long lifespan of aluminum products contributes to their overall cost-effectiveness.

Applications of Aluminum Extrusion

Aluminum extrusions are used in a wide range of industries, showcasing their versatility and adaptability. Here are some common applications:

Construction

In the construction industry, aluminum extrusions are used for window frames, curtain walls, and structural components. Their lightweight nature and resistance to corrosion make them ideal for both residential and commercial buildings.

Automotive

The automotive industry utilizes aluminum extrusions for various components, including chassis, bumpers, and heat exchangers. The lightweight properties of aluminum help improve fuel efficiency and reduce emissions.

Electronics

Aluminum extrusions are commonly used in the electronics industry for heat sinks, enclosures, and structural supports. Their excellent thermal conductivity helps dissipate heat, ensuring the longevity of electronic components.

Aerospace

In aerospace applications, aluminum extrusions are used for structural components, fuselage frames, and wing structures. The high strength-to-weight ratio of aluminum is crucial in this industry, where every ounce counts.

Furniture

Custom aluminum extrusions are increasingly used in furniture design, providing modern aesthetics and durability. From table legs to shelving systems, aluminum offers a sleek and contemporary look.

Custom Aluminum Extrusions

Custom aluminum extrusions allow manufacturers to create products that meet specific design and functional requirements. This customization can enhance product performance and aesthetics, making it a valuable option for designers and engineers.

Importance of Customization in Design

Customization is essential in today's competitive market. Off-the-shelf solutions may not always meet the unique needs of a project. Custom aluminum extrusions enable designers to create products that align with their vision, ensuring that functionality and aesthetics are both prioritized.

Case Studies of Successful Custom Extrusion Projects

1. Architectural Facades: A leading architectural firm utilized custom aluminum extrusions to create a unique facade for a high-rise building. The extrusions allowed for intricate designs while maintaining structural integrity.

2. Automotive Components: An automotive manufacturer developed a custom aluminum extrusion for a lightweight chassis. The design improved fuel efficiency and performance, showcasing the benefits of tailored solutions.

3. Consumer Electronics: A tech company used custom aluminum extrusions for a sleek laptop design. The extrusions provided a modern look while ensuring durability and heat dissipation.

Techniques in Aluminum Extrusion Manufacturing

Advancements in aluminum extrusion technology have led to the development of various techniques that enhance the manufacturing process. These techniques improve efficiency, reduce waste, and allow for more complex designs.

Advanced Manufacturing Techniques

1. Multi-Stage Extrusion: This technique involves using multiple dies to create complex profiles in a single process, reducing production time and costs.

2. Hydroforming: Hydroforming uses high-pressure fluid to shape aluminum, allowing for intricate designs that traditional extrusion methods may not achieve.

3. 3D Printing: The integration of 3D printing with aluminum extrusion is an emerging trend, enabling rapid prototyping and customization.

Innovations in Extrusion Technology

Innovations in extrusion technology continue to evolve, with a focus on sustainability and efficiency. New methods aim to reduce energy consumption and material waste, aligning with global sustainability goals.

Conclusion

Custom aluminum extrusions play a vital role in enhancing product design across various industries. Their lightweight nature, strength, and design flexibility make them an ideal choice for manufacturers looking to innovate. By understanding the aluminum extrusion process and its benefits, designers can leverage custom solutions to create unique products that meet specific needs. As technology continues to advance, the possibilities for aluminum extrusion will only expand, offering even more opportunities for creativity and efficiency in product design.

Related Questions

1. What are the advantages of using aluminum extrusions in product design?

Aluminum extrusions offer lightweight properties, high strength, design flexibility, and cost-effectiveness, making them ideal for various applications.

2. How does the aluminum extrusion process work?

The aluminum extrusion process involves heating aluminum billets, forcing them through a die to create a desired shape, cooling the extrusions, and cutting them to length.

3. What industries commonly use aluminum extrusions?

Aluminum extrusions are widely used in construction, automotive, electronics, aerospace, and furniture industries.

4. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be customized to meet specific design and functional requirements, allowing for unique product solutions.

5. What are some recent innovations in aluminum extrusion technology?

Recent innovations include multi-stage extrusion, hydroforming, and the integration of 3D printing, all aimed at improving efficiency and sustainability in the manufacturing process.