Content Menu

● Introduction

● Understanding Custom Aluminum Extrusions

● Benefits of Custom Aluminum Extrusions

>> Versatility

>> Ease of Assembly

>> Strength and Durability

>> Lightweight

● Applications of Custom Aluminum Extrusions

>> Manufacturing and Prototyping

>> Robotics

>> Construction

>> Automotive

>> Aerospace

● Choosing the Right Custom Aluminum Extrusion

>> Size and Dimensions

>> Load Capacity

>> Compatibility with Accessories

>> Surface Finish

>> Cost and Lead Time

● Conclusion

● Frequently Asked Questions

>> 1. What types of custom aluminum extrusions does McMaster-Carr offer?

>> 2. How can I submit a design for a custom aluminum extrusion?

>> 3. What is the typical lead time for custom aluminum extrusions?

>> 4. Are there minimum order quantities for custom aluminum extrusions?

>> 5. Can I get samples of custom aluminum extrusions before placing a large order?

Introduction

Aluminum extrusions have become a cornerstone in various industries due to their versatility, strength, and lightweight properties. Among the leading suppliers of aluminum extrusions is McMaster-Carr, a company renowned for its extensive catalog and high-quality products. This article delves into the custom aluminum extrusion options available at McMaster-Carr, exploring their features, benefits, and applications. Whether you are an engineer, designer, or DIY enthusiast, understanding these options can significantly enhance your projects.

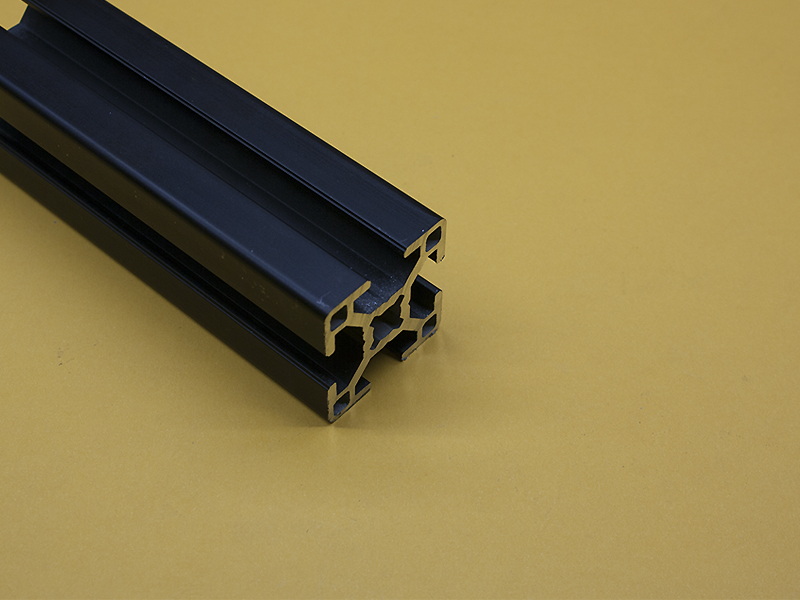

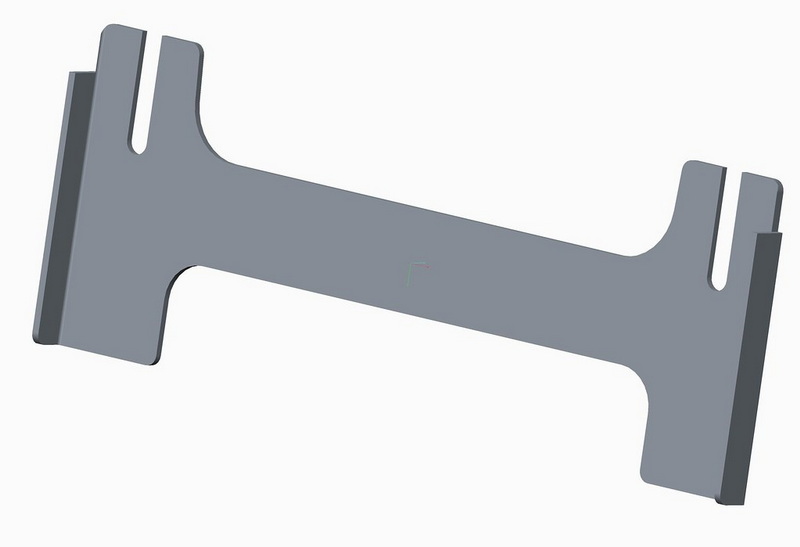

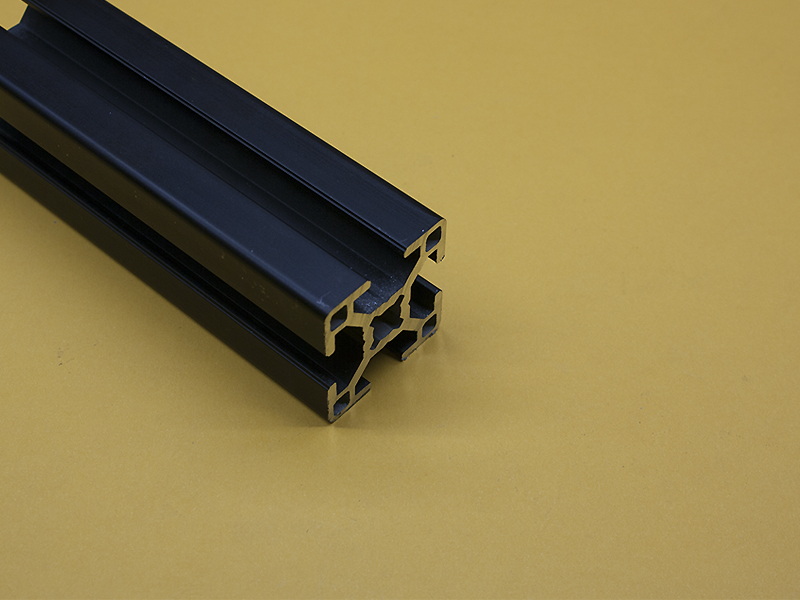

Understanding Custom Aluminum Extrusions

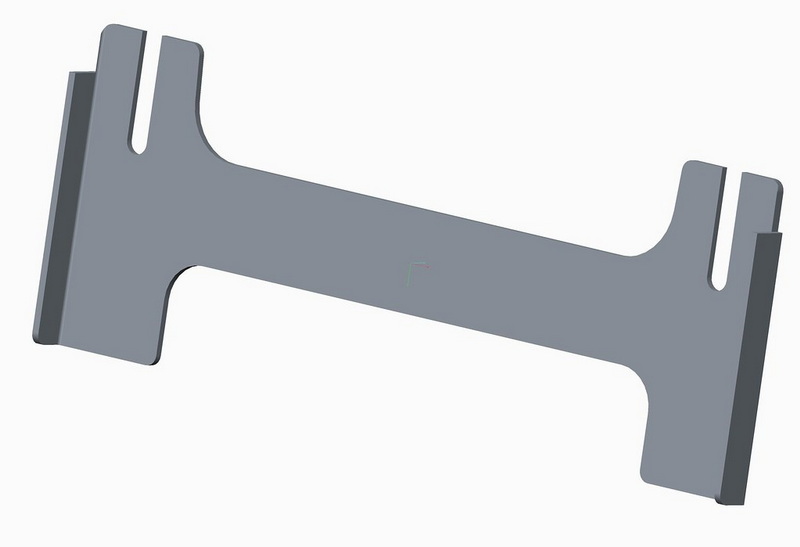

Custom aluminum extrusions are tailored profiles created to meet specific design requirements. Unlike standard extrusions, which come in predefined shapes and sizes, custom options allow for unique dimensions, cross-sections, and features. This flexibility is particularly beneficial for projects that require precise specifications or innovative designs.

At McMaster-Carr, the process of obtaining custom aluminum extrusions is straightforward. Customers can submit their design specifications, and the company will work with them to produce the desired profiles. This service is ideal for businesses looking to create specialized components for machinery, frames, or other applications.

Benefits of Custom Aluminum Extrusions

Versatility

One of the primary advantages of custom aluminum extrusions is their versatility. They can be used in a wide range of applications, from structural components in buildings to intricate parts in machinery. The ability to design a profile that fits specific needs means that engineers and designers can create solutions that are not only functional but also aesthetically pleasing.

Ease of Assembly

Custom aluminum extrusions often feature designs that facilitate easy assembly. Many profiles come with integrated slots or holes that allow for quick fastening and connection to other components. This ease of assembly can significantly reduce labor costs and time during the construction or manufacturing process.

Strength and Durability

Aluminum is known for its strength-to-weight ratio, making it an excellent choice for structural applications. Custom aluminum extrusions maintain these properties while allowing for unique designs that can enhance strength in critical areas. Additionally, aluminum is resistant to corrosion, ensuring that custom extrusions will last for years, even in harsh environments.

Lightweight

The lightweight nature of aluminum is another significant benefit. Custom aluminum extrusions can provide the necessary strength without adding excessive weight to a project. This characteristic is particularly important in industries such as aerospace and automotive, where weight reduction can lead to improved performance and fuel efficiency.

Applications of Custom Aluminum Extrusions

Custom aluminum extrusions are utilized across various industries, each benefiting from their unique properties. Here are some common applications:

Manufacturing and Prototyping

In manufacturing, custom aluminum extrusions are often used to create frames, supports, and enclosures for machinery. Their ability to be tailored to specific dimensions makes them ideal for prototyping new products. Engineers can quickly design and test components, making adjustments as needed without the long lead times associated with traditional manufacturing methods.

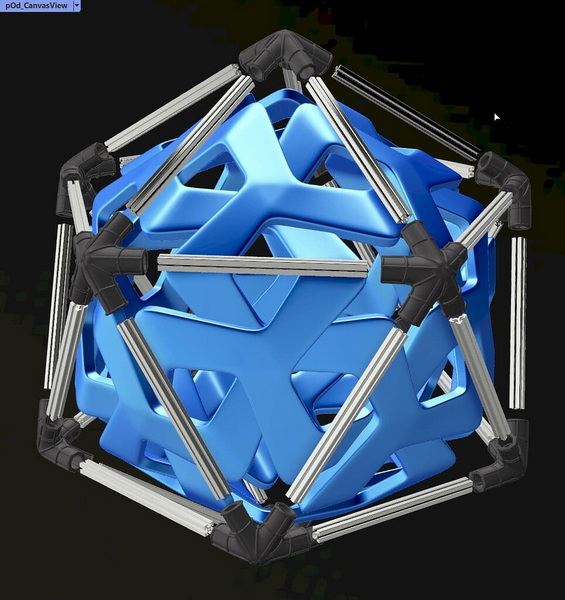

Robotics

The robotics industry frequently employs custom aluminum extrusions to build lightweight yet robust structures. The modular nature of these extrusions allows for easy reconfiguration and expansion of robotic systems. This adaptability is crucial in a field where technology evolves rapidly, and designs must be updated frequently.

Construction

In construction, custom aluminum extrusions are used for window frames, curtain walls, and other architectural elements. Their aesthetic appeal, combined with their strength and durability, makes them a popular choice for modern buildings. Additionally, the ease of assembly can lead to faster construction times, benefiting both contractors and clients.

Automotive

The automotive industry utilizes custom aluminum extrusions for various components, including chassis, frames, and body panels. The lightweight nature of aluminum helps improve fuel efficiency while maintaining structural integrity. Custom profiles can be designed to meet specific performance requirements, ensuring that vehicles are both safe and efficient.

Aerospace

In aerospace applications, custom aluminum extrusions are critical for creating lightweight structures that can withstand extreme conditions. The ability to design profiles that meet stringent safety and performance standards is essential in this industry. Custom extrusions can be used in everything from aircraft frames to satellite components.

Choosing the Right Custom Aluminum Extrusion

When selecting a custom aluminum extrusion, several factors should be considered:

Size and Dimensions

The first step in choosing a custom aluminum extrusion is determining the required size and dimensions. McMaster-Carr offers a variety of options, allowing customers to specify the exact measurements needed for their projects. This precision ensures that the extrusion will fit seamlessly into the intended application.

Load Capacity

Understanding the load capacity of the extrusion is crucial, especially for structural applications. Custom profiles can be designed to distribute weight effectively, ensuring that they can support the necessary loads without compromising safety.

Compatibility with Accessories

Many custom aluminum extrusions are designed to work with a range of accessories, such as connectors, brackets, and fasteners. When selecting an extrusion, it is essential to consider which accessories will be used and ensure compatibility. McMaster-Carr provides a wide selection of accessories that can enhance the functionality of custom extrusions.

Surface Finish

The surface finish of the aluminum extrusion can impact its appearance and performance. Options such as anodizing or powder coating can provide additional protection against corrosion and wear while enhancing the aesthetic appeal. Customers should consider the environment in which the extrusion will be used when selecting a surface finish.

Cost and Lead Time

Finally, it is essential to consider the cost and lead time associated with custom aluminum extrusions. While custom options may be more expensive than standard profiles, the benefits they provide can outweigh the costs. Additionally, McMaster-Carr is known for its efficient production processes, often delivering custom extrusions in a timely manner.

Conclusion

Custom aluminum extrusions from McMaster-Carr offer a wealth of options for engineers, designers, and manufacturers. Their versatility, ease of assembly, strength, and lightweight properties make them an ideal choice for a wide range of applications. By understanding the benefits and considerations associated with custom extrusions, you can make informed decisions that enhance your projects and drive innovation.

Frequently Asked Questions

1. What types of custom aluminum extrusions does McMaster-Carr offer?

McMaster-Carr offers a wide variety of custom aluminum extrusions, including T-slot profiles, structural shapes, and specialized designs tailored to specific applications.

2. How can I submit a design for a custom aluminum extrusion?

To submit a design for a custom aluminum extrusion, you can contact McMaster-Carr directly through their website or customer service. They will guide you through the process and help you finalize your specifications.

3. What is the typical lead time for custom aluminum extrusions?

The lead time for custom aluminum extrusions can vary based on the complexity of the design and current production schedules. However, McMaster-Carr is known for its efficient processes and often provides quick turnaround times.

4. Are there minimum order quantities for custom aluminum extrusions?

Minimum order quantities for custom aluminum extrusions may apply, depending on the specific design and production requirements. It is best to check with McMaster-Carr for details regarding your particular order.

5. Can I get samples of custom aluminum extrusions before placing a large order?

Many suppliers, including McMaster-Carr, may offer samples of custom aluminum extrusions upon request. This allows you to evaluate the quality and suitability of the extrusion for your project before committing to a larger order.