Content Menu

● 1. Lightweight Yet Strong

● 2. High Strength-to-Weight Ratio

● 3. Corrosion Resistance

● 4. Design Flexibility

● 5. Excellent Thermal and Electrical Conductivity

● 6. Sustainability and Recyclability

● 7. Cost-Effectiveness

● 8. Non-Toxic and Non-Combustible

● 9. Quick Turnaround Times

● 10. Seamless Construction

● 11. Aesthetic Appeal

● 12. Low Maintenance Requirements

● Conclusion

● Frequently Asked Questions

>> 1. What industries benefit from aluminum extrusion?

>> 2. How does aluminum extrusion compare with other manufacturing processes?

>> 3. What are the common finishes available for aluminum extrusions?

>> 4. Can custom shapes be created through aluminum extrusion?

>> 5. Is aluminum extrusion environmentally friendly?

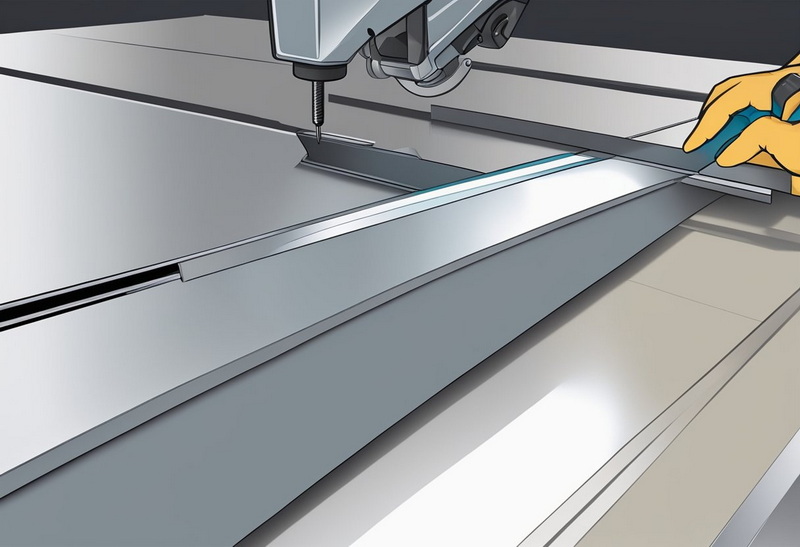

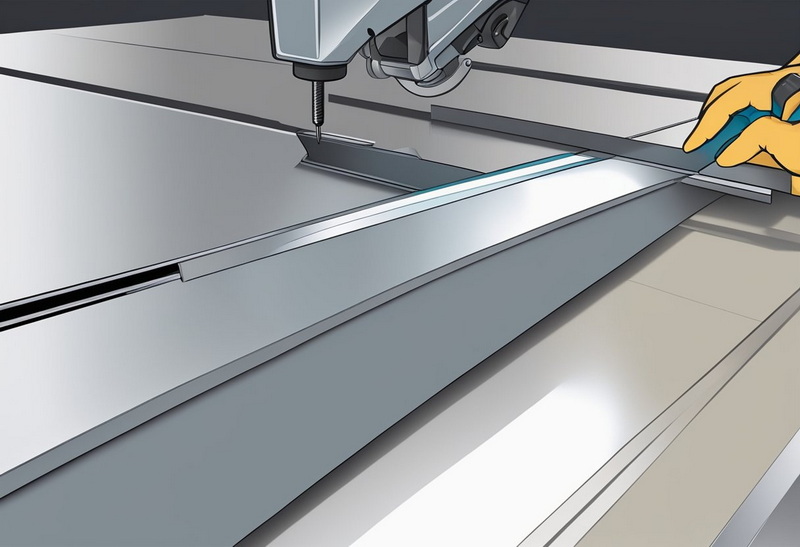

Aluminum extrusion is a manufacturing process that shapes aluminum into desired profiles by forcing it through a die. This technique is widely used across various industries due to its numerous advantages, especially in Dallas, TX, where the demand for aluminum products continues to grow. This article will explore the top benefits of aluminum extrusion, emphasizing its importance in the Dallas market.

1. Lightweight Yet Strong

One of the most significant advantages of aluminum extrusion is its lightweight nature combined with high strength. Aluminum has approximately one-third the weight of steel, making it easier to handle and transport. This characteristic is particularly beneficial in applications where weight reduction is crucial, such as in automotive and aerospace industries. In Dallas, manufacturers leverage this property to create components that require both strength and reduced weight.

The lightweight nature of aluminum also contributes to energy efficiency in transportation. For example, lighter vehicles consume less fuel, which is a critical consideration for automotive manufacturers in Dallas looking to meet environmental standards and reduce operational costs. Additionally, this property allows for innovative designs that can improve performance without compromising safety.

2. High Strength-to-Weight Ratio

Aluminum extrusions possess an exceptional strength-to-weight ratio, making them ideal for structural applications. This means that components can support heavy loads without adding excessive weight. In construction projects throughout Dallas, this property allows for innovative designs that maintain structural integrity while minimizing material costs.

For instance, aluminum extrusions are often used in building frameworks, window frames, and roofing systems. Their ability to withstand significant stress while remaining lightweight enables architects and engineers to design structures that are not only aesthetically pleasing but also structurally sound. This versatility is particularly valuable in urban environments like Dallas, where space is at a premium.

3. Corrosion Resistance

Aluminum naturally forms a protective oxide layer when exposed to air, which makes it highly resistant to corrosion. This quality is particularly advantageous for outdoor applications in Dallas, where weather conditions can vary significantly. The longevity provided by this resistance reduces maintenance costs and extends the lifespan of products made from aluminum extrusions.

Moreover, this corrosion resistance makes aluminum an ideal choice for marine applications or structures exposed to harsh environments. Manufacturers in Dallas can produce components that will endure the test of time without succumbing to rust or degradation, ensuring reliability and safety for end-users.

4. Design Flexibility

The extrusion process allows for a high degree of design flexibility. Manufacturers can create complex shapes and profiles tailored to specific applications without the need for additional components or welding. This capability is especially beneficial for custom projects in Dallas, where unique architectural designs are often required.

Aluminum extrusions can be produced in various shapes, including hollow tubes, solid bars, and intricate profiles with multiple features. This adaptability enables designers to innovate freely while maintaining functionality and aesthetics. Additionally, the ability to produce custom dies means that manufacturers can quickly respond to market demands with new designs.

5. Excellent Thermal and Electrical Conductivity

Aluminum is an excellent conductor of heat and electricity, making it suitable for various applications, including heat exchangers and electrical connectors. In Dallas's growing tech industry, aluminum extrusions are increasingly used in electronic housings and cooling systems due to their efficient thermal management properties.

This conductivity also makes aluminum an ideal material for LED lighting fixtures and other electrical components that require efficient heat dissipation. As energy-efficient technologies continue to advance, the demand for aluminum extrusions in electrical applications is expected to rise significantly.

6. Sustainability and Recyclability

Aluminum is one of the most sustainable materials available; it can be recycled without losing quality. The recycling process requires only 5% of the energy needed to produce new aluminum from ore. This eco-friendly aspect appeals to many businesses in Dallas that prioritize sustainability in their operations.

Moreover, using recycled aluminum significantly reduces greenhouse gas emissions compared to primary production processes. As more companies adopt sustainable practices and seek eco-friendly materials, aluminum extrusion will play a pivotal role in achieving these goals while maintaining product quality.

7. Cost-Effectiveness

Using aluminum extrusions can lead to lower overall production costs due to reduced material waste during manufacturing and lower shipping costs due to their lightweight nature. Additionally, the long-term durability and low maintenance requirements associated with aluminum products contribute to their cost-effectiveness over time.

In competitive markets like Dallas, where businesses strive for profitability while maintaining high-quality standards, the cost-effectiveness of aluminum extrusion becomes a key selling point. Companies can achieve significant savings on both production and operational costs by choosing aluminum over heavier or less durable materials.

8. Non-Toxic and Non-Combustible

Aluminum does not emit toxic fumes even at high temperatures, making it a safe choice for various applications. Its non-combustible nature further enhances its appeal for use in environments where fire safety is a concern.

This property makes aluminum an excellent choice for building materials in residential and commercial construction projects throughout Dallas. Architects and builders can incorporate aluminum extrusions into designs while ensuring compliance with safety regulations regarding fire hazards.

9. Quick Turnaround Times

The aluminum extrusion process allows for rapid production cycles, enabling manufacturers in Dallas to meet tight deadlines and respond quickly to market demands. This efficiency is crucial in industries such as construction and automotive, where time-to-market can significantly impact profitability.

With advancements in technology and automation within extrusion facilities, manufacturers can produce high volumes of custom parts quickly without sacrificing quality or precision. This capability not only supports local businesses but also strengthens the overall economy by fostering innovation and competitiveness.

10. Seamless Construction

Extruded aluminum products often feature seamless designs that enhance their strength and reduce potential weak points found in mechanically joined assemblies. This characteristic is particularly beneficial for structural applications where integrity is paramount.

Seamless construction minimizes the risk of failure due to joint weaknesses or stress concentrations commonly found in welded or bolted assemblies. As a result, manufacturers can provide safer and more reliable products that meet stringent industry standards.

11. Aesthetic Appeal

Aluminum extrusions offer a modern aesthetic that appeals to designers across various industries. The ability to create sleek profiles with smooth finishes allows architects and product designers to incorporate aluminum into contemporary designs effectively.

In Dallas's vibrant architectural landscape, where aesthetics play a crucial role in attracting clients and residents alike, the visual appeal of aluminum extrusions cannot be overstated. From elegant storefronts to stylish residential buildings, aluminum contributes significantly to the overall look and feel of urban environments.

12. Low Maintenance Requirements

Another benefit of using aluminum extrusions is their low maintenance requirements compared to other materials like wood or steel that may require regular painting or treatment against corrosion or pests. Aluminum's natural resistance means it often only needs occasional cleaning with soap and water.

This low-maintenance characteristic is particularly appealing for businesses looking to reduce long-term operational costs associated with upkeep while maintaining a professional appearance.

Conclusion

In conclusion, aluminum extrusion offers a multitude of benefits that make it an attractive option for manufacturers and designers alike in Dallas, TX. From its lightweight yet strong properties to its corrosion resistance and design flexibility, aluminum extrusions are well-suited for various applications across multiple industries including construction, automotive manufacturing, electronics production, and more.

As the demand for sustainable materials continues to rise alongside technological advancements within manufacturing processes—aluminum extrusion will likely play an increasingly vital role in shaping the future of manufacturing not just locally but globally as well.

Frequently Asked Questions

1. What industries benefit from aluminum extrusion?

Aluminum extrusion serves a wide range of industries including construction, automotive, aerospace, electrical components manufacturing, packaging solutions providers as well as consumer goods sectors such as furniture design companies.

2. How does aluminum extrusion compare with other manufacturing processes?

Compared to casting or machining processes—aluminum extrusion offers better precision with less material waste during production cycles allowing manufacturers greater design freedom without requiring additional assembly processes which could increase costs or lead times unnecessarily.

3. What are the common finishes available for aluminum extrusions?

Common finishes include anodizing (which enhances corrosion resistance), powder coating (providing color options), mill finish (for a raw aesthetic), as well as various polishing techniques depending on desired final appearance requirements set by clients or projects themselves.

4. Can custom shapes be created through aluminum extrusion?

Yes! One primary advantage of utilizing this method lies within its ability—manufacturers can produce custom shapes tailored specifically towards individual client needs without requiring additional parts or assembly which saves both time & money during development phases!

5. Is aluminum extrusion environmentally friendly?

Yes! Aluminum is highly recyclable without losing quality—making it an environmentally friendly choice compared against other materials that may degrade during recycling processes; thus supporting sustainability efforts being adopted by many businesses today!