Content Menu

● Understanding Aluminum Extrusion

● Key Players in the Mexican Aluminum Extrusion Market

>> 1. ABC Aluminum Solutions

>> 2. CUPRUM Group

>> 3. Valsa

>> 4. Alucomex

>> 5. Canalum

● The Role of Technology in Aluminum Extrusion

● Market Trends Influencing Aluminum Extrusion in Mexico

● Trade Dynamics Affecting Aluminum Extrusion

● Challenges Facing Aluminum Extrusion Companies

● Future Outlook for Aluminum Extrusion Companies in Mexico

● Conclusion

● FAQ

>> 1. What is aluminum extrusion?

>> 2. Why is aluminum preferred for manufacturing?

>> 3. How many presses does CUPRUM operate?

>> 4. What sectors do ABC Aluminum Solutions serve?

>> 5. How does Canalum support its members?

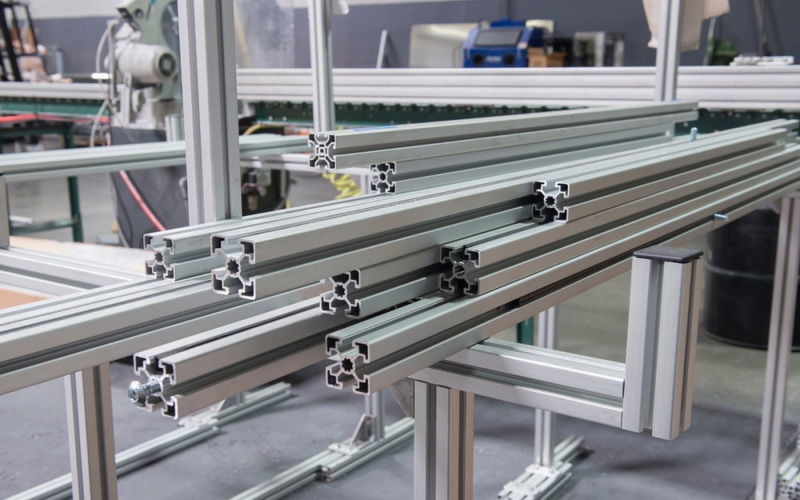

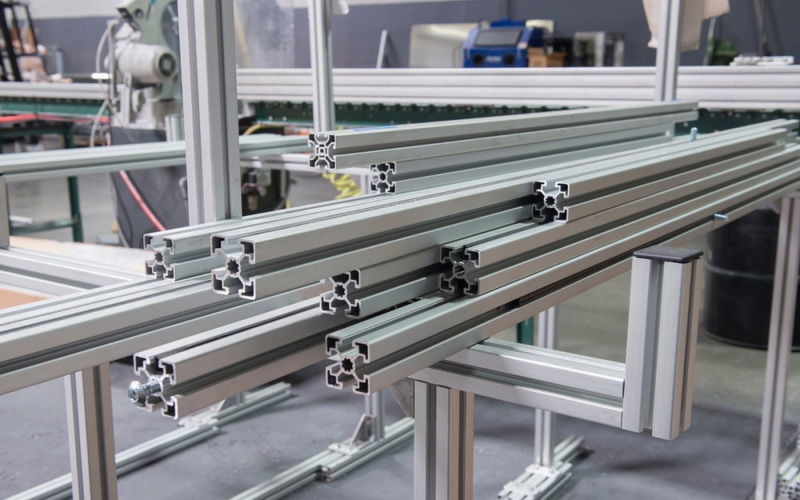

Aluminum extrusion is a vital process in the manufacturing industry, especially in sectors such as construction, automotive, and aerospace. Mexico has emerged as a significant player in the aluminum extrusion market due to its strategic location, skilled workforce, and robust manufacturing capabilities. This article delves into the top aluminum extrusion companies in Mexico, highlighting their services, innovations, and contributions to the industry.

Understanding Aluminum Extrusion

Aluminum extrusion is a process where aluminum alloy is forced through a die to create objects with a fixed cross-sectional profile. This method is widely used because of aluminum's lightweight nature, strength, and resistance to corrosion. The extruded products are utilized in various applications, including:

- Construction: Window frames, doors, and structural components.

- Automotive: Lightweight parts that enhance fuel efficiency.

- Aerospace: Components that require high strength-to-weight ratios.

Key Players in the Mexican Aluminum Extrusion Market

Several companies dominate the aluminum extrusion landscape in Mexico. Here are some of the leading players:

1. ABC Aluminum Solutions

ABC Aluminum Solutions is recognized as one of the top aluminum extrusion companies in Mexico. With over 30 years of experience, they specialize in manufacturing high-quality aluminum profiles for various industries.

- Services: They offer a comprehensive range of services from extrusion to finishing and assembly.

- Market Reach: Their products serve sectors such as construction, renewable energy, and automotive.

- Innovation: The company invests heavily in technology and equipment to enhance production efficiency and product quality.

2. CUPRUM Group

CUPRUM is the largest aluminum extrusion manufacturer in Latin America. Established in 1948, CUPRUM has expanded its operations significantly over the decades.

- Facilities: They operate three major extrusion divisions located in Monterrey, Mexico City, and Guadalajara.

- Production Capacity: With 18 presses by 2017, CUPRUM produces a wide range of aluminum profiles for architectural and industrial applications.

- Sustainability Efforts: The company focuses on energy-efficient technologies and environmentally friendly practices.

3. Valsa

Valsa has been a key player in the aluminum extrusion industry for over 55 years. They are known for their high-quality manufacturing processes and innovative solutions.

- Product Range: Valsa specializes in producing aluminum profiles for construction, automotive, and industrial sectors.

- Technology: Their state-of-the-art technological infrastructure ensures high levels of quality and specialization.

- Customer Focus: Valsa prioritizes customer satisfaction by providing tailored solutions to meet specific needs.

4. Alucomex

Alucomex is another prominent aluminum extrusion company that has established itself as a leader in the market.

- Expertise: They focus on producing high-quality aluminum profiles for diverse applications.

- Innovation: Alucomex invests in modern technology to improve production processes and product quality.

- Industry Impact: Their products are widely used across various sectors including construction and automotive.

5. Canalum

Canalum represents a collective of aluminum manufacturers in Mexico, advocating for the industry's interests.

- Industry Representation: They work closely with government entities to ensure fair trade practices within the sector.

- Support for Manufacturers: Canalum provides resources and support for companies facing challenges related to trade policies.

- Focus on Transparency: The organization emphasizes transparency and collaboration among its members to strengthen the industry.

The Role of Technology in Aluminum Extrusion

The advancement of technology plays a crucial role in enhancing the efficiency and quality of aluminum extrusion processes. Companies are increasingly adopting automated systems and advanced machinery to streamline production. For instance:

- High-Tech Equipment: Investments in state-of-the-art presses and furnaces improve productivity while reducing waste.

- Quality Control Systems: Implementing rigorous quality control measures ensures that products meet international standards.

Recent advancements have also introduced:

- Nano-Coating Technologies: These enhance durability by providing an extra layer of protection against corrosion and abrasion. This significantly extends the lifespan of extruded products across various applications.

- AI-Powered Precision Control Solutions: Integrating artificial intelligence allows manufacturers to analyze real-time data from machinery, enabling immediate adjustments that ensure each profile adheres to exact specifications. This not only enhances product quality but also boosts resource efficiency.

Market Trends Influencing Aluminum Extrusion in Mexico

Several trends are shaping the future of aluminum extrusion companies in Mexico:

- Increased Demand from Automotive Sector: As global automakers invest heavily in Mexico, there is a growing demand for lightweight materials like aluminum to improve fuel efficiency.

- Sustainability Initiatives: Companies are focusing on sustainable practices by reducing energy consumption during production and increasing recycling efforts.

- Technological Advancements: Continuous innovation in manufacturing processes helps companies stay competitive by improving product quality and reducing costs.

Trade Dynamics Affecting Aluminum Extrusion

The Mexican aluminum extrusion market is also influenced by trade dynamics both regionally and globally. Recent changes include:

- Tariffs on Aluminum Imports: In April 2024, Mexico announced tariffs ranging from 20% to 35% on several aluminum products due to pressure from U.S. trade officials. This move aimed to combat the influx of subsidized Chinese metal into Mexico but raised concerns about increased costs for Mexican manufacturers who rely on imported materials.

- Revocation of Tariffs on Unwrought Aluminum: In May 2023, Mexico revoked tariffs specifically on unwrought aluminum imports while maintaining tariffs on extruded products. This decision was made amidst concerns that tariffs could lead to higher prices for consumers and reduced competitiveness for local manufacturers.

These trade policies have significant implications for both domestic producers and international players looking to enter or expand within the Mexican market.

Challenges Facing Aluminum Extrusion Companies

While opportunities abound within the Mexican aluminum extrusion sector, several challenges persist:

- Supply Chain Disruptions: Global supply chain issues have affected material availability and pricing stability. Companies must navigate these disruptions while maintaining production schedules.

- Competition from International Markets: The influx of cheaper imported products can pressure local manufacturers to lower prices or innovate rapidly to maintain market share.

- Regulatory Compliance: Adhering to evolving regulations regarding environmental impact and trade can be complex but is necessary for long-term sustainability.

Future Outlook for Aluminum Extrusion Companies in Mexico

The future looks promising for aluminum extrusion companies operating in Mexico. With continued investment in technology, growing demand across various sectors, and an emphasis on sustainability practices, these companies are well-positioned for growth.

As they adapt to changing market conditions—such as fluctuating tariffs and increased competition—companies that prioritize innovation will likely emerge as leaders within this dynamic industry landscape.

Conclusion

The aluminum extrusion industry in Mexico is thriving due to the presence of several leading companies that prioritize quality, innovation, and customer satisfaction. ABC Aluminum Solutions, CUPRUM Group, Valsa, Alucomex, and Canalum are at the forefront of this growth, contributing significantly to various sectors such as construction and automotive. As technology continues to evolve and demand increases, these companies are well-positioned to lead the way in sustainable practices and innovative solutions.

FAQ

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create objects with specific cross-sectional profiles used across various industries.

2. Why is aluminum preferred for manufacturing?

Aluminum is lightweight, strong, resistant to corrosion, and has excellent thermal conductivity, making it ideal for many applications including automotive parts and construction materials.

3. How many presses does CUPRUM operate?

CUPRUM operates 18 presses across its three divisions located in Monterrey, Mexico City, and Guadalajara.

4. What sectors do ABC Aluminum Solutions serve?

ABC Aluminum Solutions serves multiple sectors including construction, renewable energy, industrial machinery, automotive transportation among others.

5. How does Canalum support its members?

Canalum supports its members by advocating for fair trade practices, providing resources for navigating trade policies, and promoting transparency within the industry.

Come and contact us to shop! ! !