Content Menu

● Introduction to the Ender 3 and Aluminum Extruders

>> Benefits of Aluminum Extruders

● Step-by-Step Guide to Upgrading Your Ender 3 with an Aluminum Extruder

>> Step 1: Prepare Your Work Area

>> Step 2: Remove the Stock Extruder

>> Step 3: Install the New Aluminum Extruder

>> Step 4: Calibrate and Test

● Factors to Consider When Upgrading

● Maintaining Your Aluminum Extruder

● Community Insights and Reviews

● Conclusion

● FAQs

>> 1. What are the benefits of upgrading to an aluminum extruder on the Ender 3?

>> 2. How long does it take to upgrade the Ender 3 with an aluminum extruder?

>> 3. Do I need special tools for this upgrade?

>> 4. Will I need to recalibrate my printer after upgrading?

>> 5. Can I use flexible filaments with an aluminum extruder?

● Citations:

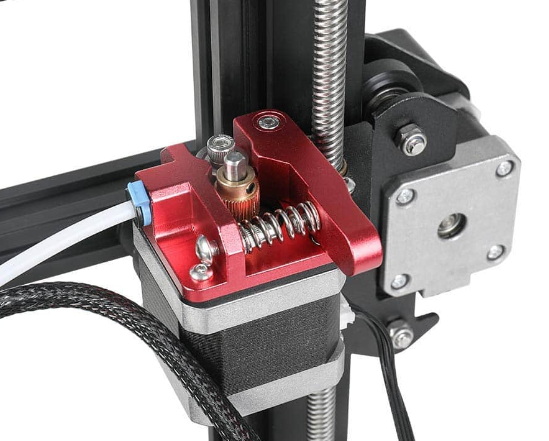

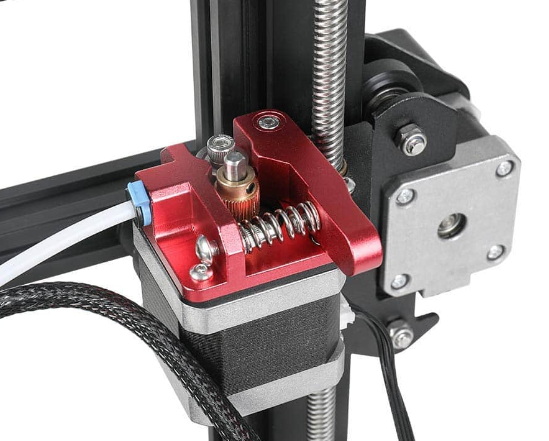

Upgrading your Ender 3 with an aluminum extruder is a straightforward yet impactful modification that can significantly enhance your 3D printing experience. The stock plastic extruder, while functional, often suffers from wear and tear, leading to inconsistent filament feeding and reduced print quality. In this comprehensive guide, we will walk you through the step-by-step process of installing an aluminum extruder on your Ender 3, highlighting the benefits, necessary tools, and tips for optimal performance.

Introduction to the Ender 3 and Aluminum Extruders

The Creality Ender 3 is a popular and versatile 3D printer, widely used by hobbyists and professionals alike. Its affordability and ease of modification make it an ideal platform for upgrades. One of the most common and beneficial upgrades is replacing the stock plastic extruder with an aluminum one. Aluminum extruders offer increased durability, improved heat dissipation, and more consistent filament feeding, leading to better print quality and reliability.

Benefits of Aluminum Extruders

- Durability: Aluminum is more resistant to wear and tear compared to plastic, ensuring that the extruder can handle the stresses of filament feeding without breaking or deforming.

- Consistency: The rigid construction of an aluminum extruder ensures consistent filament feeding, leading to better print quality.

- Heat Dissipation: Aluminum conducts heat more effectively, reducing the risk of heat-related issues that can lead to jamming.

- Flexibility: Aluminum extruders are better suited for handling flexible filaments due to their robust design.

Step-by-Step Guide to Upgrading Your Ender 3 with an Aluminum Extruder

Step 1: Prepare Your Work Area

Before starting the upgrade, ensure your workspace is clean and well-lit. Gather all necessary tools and components:

- Allen wrenches (1.5mm, 2mm, and 2.5mm)

- Screwdriver

- Pliers (optional)

- New aluminum extruder kit

- Turn off your Ender 3 and unplug it to prevent any electrical issues.

Step 2: Remove the Stock Extruder

1. Unload Filament: Heat up the hotend and remove any filament from the extruder.

2. Unscrew the Coupling: Use a 2mm Allen wrench to unscrew the coupling holding the Bowden tube in place.

3. Disconnect the Stepper Motor: Remove the screws attaching the stepper motor to the extruder body. Hold the motor while unscrewing to prevent it from falling.

4. Detach the Lever Arm: Unscrew and remove the lever arm from the old extruder assembly.

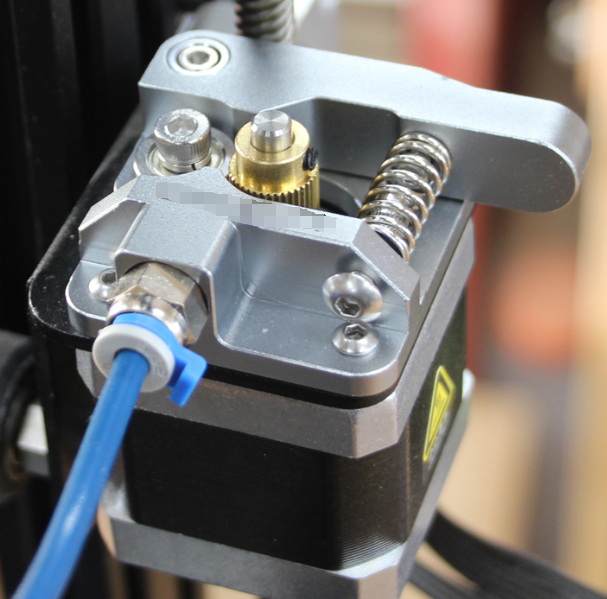

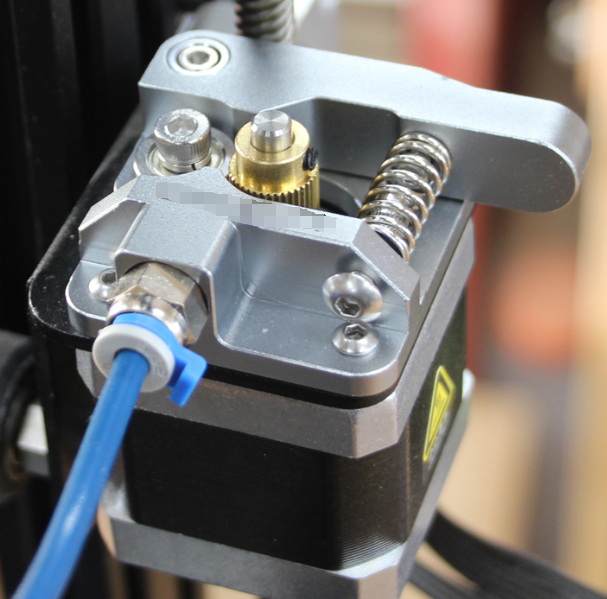

Step 3: Install the New Aluminum Extruder

1. Attach the Base Plate: Place the new aluminum base plate onto the motor. Secure it using screws provided in your kit.

2. Install Gear: Slide on the new gear onto the motor shaft, ensuring one of its grub screws aligns with the flat part of the motor shaft for a secure fit.

3. Assemble Lever Arm: Attach the lever arm and idler pulley using screws, ensuring that it can pivot freely.

4. Reconnect Bowden Tube: Insert and secure the Bowden tube into its new coupling on the aluminum extruder.

5. Reconnect Wiring: Plug back in any electrical connectors that were disconnected during disassembly.

Step 4: Calibrate and Test

1. Power On Your Printer: Turn on your Ender 3 and perform a test print to ensure everything is functioning correctly.

2. Calibrate E-Steps: After changing your extruder, it's crucial to recalibrate your e-steps for accurate filament extrusion.

Factors to Consider When Upgrading

- Compatibility: Ensure that your chosen aluminum extruder is compatible with your specific model of Ender 3 (e.g., Pro or V2).

- Type of Filament Used: If you plan on using flexible filaments frequently, consider a dual-gear or direct drive system for optimal performance.

- Installation Difficulty: Some kits may require more technical skill than others; choose one that matches your comfort level with DIY projects.

Maintaining Your Aluminum Extruder

Regular maintenance is crucial for optimal performance:

1. Regular Cleaning: Periodically clean the extruder gear to remove any accumulated debris or filament residue. Use a brush or compressed air to dislodge any particles.

2. Check Tension: Ensure that tension on the extruder arm is properly adjusted. Too little tension can cause filament slippage, while too much tension can deform it.

3. Inspect for Wear: Regularly inspect for signs of wear or damage; replace any worn parts promptly to prevent further issues.

4. Lubricate Moving Parts: Apply a small amount of lubricant designed for 3D printer components to keep moving parts running smoothly.

Community Insights and Reviews

Many users in the 3D printing community have shared their experiences with aluminum extruder upgrades on the Ender 3:

- Positive Feedback: Most users report noticeable improvements in print quality and reliability after upgrading to an aluminum extruder.

- Installation Tips: Users recommend watching video tutorials and reading online guides before attempting installation for better understanding and fewer mistakes.

- Calibration Advice: Many emphasize recalibrating printer settings after installation for optimized performance post-upgrade.

Conclusion

Upgrading your Ender 3 with an aluminum extruder is a worthwhile investment for improving print quality, consistency, and the overall lifespan of your 3D printer. By following this step-by-step guide and considering the factors discussed, you can successfully enhance your printing experience.

FAQs

1. What are the benefits of upgrading to an aluminum extruder on the Ender 3?

- Upgrading to an aluminum extruder provides increased durability, consistent filament feeding, improved print quality, and flexibility with different filament types. It also enhances heat dissipation and reduces jamming issues.

2. How long does it take to upgrade the Ender 3 with an aluminum extruder?

- The upgrade process typically takes about 30 minutes to an hour, depending on your familiarity with disassembling printer components.

3. Do I need special tools for this upgrade?

- You will need basic tools such as Allen wrenches (1.5mm, 2mm, and 2.5mm) and a screwdriver. These are commonly included with most printer kits.

4. Will I need to recalibrate my printer after upgrading?

- Yes, recalibrating your e-steps is essential after replacing any components related to filament feeding for accurate prints.

5. Can I use flexible filaments with an aluminum extruder?

- Yes, aluminum extruders are better suited for handling flexible filaments compared to plastic ones due to their robust design. However, for optimal results, consider using a dual-gear or direct drive system.

Citations:

[1] https://www.yjing-extrusion.com/how-to-upgrade-to-an-ender-3-aluminum-extruder.html

[2] https://www.youtube.com/watch?v=k6eDBkc1mDg

[3] https://www.youtube.com/watch?v=nCb_94RTXCU

[4] https://www.yjing-extrusion.com/can-you-use-an-aluminum-extruder-on-ender-3.html

[5] https://www.yjing-extrusion.com/can-the-ender-3-v2-aluminum-extruder-solve-jamming-issues.html

[6] https://www.yjing-extrusion.com/what-are-the-steps-to-install-an-aluminum-extruder-on-your-ender-3.html

[7] https://www.yjing-extrusion.com/is-the-ender-3-aluminum-extruder-assembly-worth-the-investment.html

[8] https://www.crealityexperts.com/creality-extruder-upgrade-instructions

[9] https://www.youtube.com/watch?v=uyFGLYJZfrM

[10] https://www.youtube.com/watch?v=rzNmFK2zIWo

[11] https://www.yjing-extrusion.com/how-do-i-assemble-the-ender-3-aluminum-extruder.html

[12] https://www.youtube.com/watch?v=ikVFselJO4Y

[13] https://www.homebuiltworkshop.com/2022/02/19/installing-an-all-metal-extruder-on-my-creality-ender-3-v2/

[14] https://www.youtube.com/watch?v=VrqZgU8G3rQ

[15] https://www.youtube.com/watch?v=UtemZqFJ5rY

[16] https://www.reddit.com/r/ender3v2/comments/v6mmkl/getting_ready_to_add_an_all_metal_extruder/

[17] https://www.youtube.com/watch?v=pVFlGRmqNxI

[18] https://www.youtube.com/watch?v=Z5JmfNRNmtU

[19] https://letsprint3d.net/how-to-upgrade-the-extruder-ender-3/

[20] https://www.aliexpress.com/item/1005006523519131.html

[21] https://www.youtube.com/watch?v=i9pMitWixy0

[22] https://www.youtube.com/watch?v=BUFC9YDIiLg

[23] https://www.reddit.com/r/ender3/comments/eqeddp/the_all_aluminum_extruder_upgrade_is_only_ten/

[24] https://www.ebay.com.au/itm/313533164162

[25] https://www.youtube.com/watch?v=aKDym_qGLEw

[26] https://www.youtube.com/watch?v=FhiPiCln63w

[27] https://cs3d.com.au/products/rhs-pro-aluminum-extruder-upgrade-kit-mk8-drive-feed-3d-creality-ender-3-cr-10

[28] https://support.th3dstudio.com/helpcenter/upgraded-aluminum-extruder-installation-video-v2/

[29] https://www.harveynorman.com.au/creality-grey-metal-aluminum-extruder-upgrade-kit-for-ender-3.html

[30] https://www.reddit.com/r/ender3v2/comments/193nzb0/i_upgraded_to_the_all_metal_extruder_and_now_the/

[31] https://www.thingiverse.com/groups/ender3/forums/general/topic:41359

[32] https://www.yjing-extrusion.com/what-causes-slipping-in-ender-3-aluminum-extruder.html

[33] https://print3d.world/simple-free-ender-3-extruder-fix-tension-mod/

[34] https://forum.creality.com/t/ender-v1-sprite-all-metal-upgrade-issue/4080

[35] https://www.youtube.com/watch?v=zJRxRVN3p3Y

[36] https://www.youtube.com/watch?v=RLsALMPDb84

[37] https://www.youtube.com/watch?v=Ns7lH_FjX6M

[38] https://forum.creality.com/t/extruder-gear-slipping-sometimes/13948

[39] https://images-na.ssl-images-amazon.com/images/I/A1RtrhQ8ZOL.pdf

[40] https://www.youtube.com/watch?v=OgI-rJljayY

[41] https://www.reddit.com/r/ender3v2/comments/149wfud/metal_extruder_upgrade/

[42] https://kiwi3d.co.nz/product/aluminum-alloy-extruder-kit/

[43] https://www.youtube.com/watch?v=KRxMu7xp2tI

[44] https://www.youtube.com/watch?v=m6dRh0oVzhc