Content Menu

● Introduction to Aluminum Extrusion

● Top Aluminum Extrusion Equipment Suppliers

>> 1. Yejing Machinery Manufacturing Co., Ltd.

>> 2. Adex Technologies

>> 3. Gemini Group

>> 4. Diamond America

>> 5. Erd Metal

● Key Features of Trusted Suppliers

● Industry Trends and Innovations

>> 1. Industry Trends

>> 2. Technological Innovations

>> 3. Market Dynamics

● Challenges Facing the Industry

● Market Analysis

● Future Trends

● Conclusion

● FAQs

>> 1. What is the role of aluminum extrusion equipment suppliers in the manufacturing process?

>> 2. How do suppliers ensure the quality of aluminum extrusion equipment?

>> 3. What are the key challenges faced by aluminum extrusion equipment suppliers?

>> 4. What are the benefits of working with trusted aluminum extrusion equipment suppliers?

>> 5. How do advancements in technology impact aluminum extrusion equipment suppliers?

● Citations:

The aluminum extrusion industry is a vital sector that supplies components to various fields, including construction, automotive, and aerospace. The process involves forcing aluminum alloy through a die to create profiles with specific cross-sectional shapes. This article will explore the most trusted aluminum extrusion equipment suppliers in the market, highlighting their products, services, and what makes them stand out.

Introduction to Aluminum Extrusion

Aluminum extrusion is a manufacturing process that transforms aluminum alloy into profiles with precise shapes. The process involves several key steps:

1. Die Preparation: The extrusion die is preheated to ensure uniform metal flow and longevity.

2. Billet Preheating: The aluminum billet is heated to make it malleable.

3. Extrusion: The billet is pressed through the die under high pressure.

4. Cooling and Finishing: The extruded profile is cooled and processed for final use.

Top Aluminum Extrusion Equipment Suppliers

1. Yejing Machinery Manufacturing Co., Ltd.

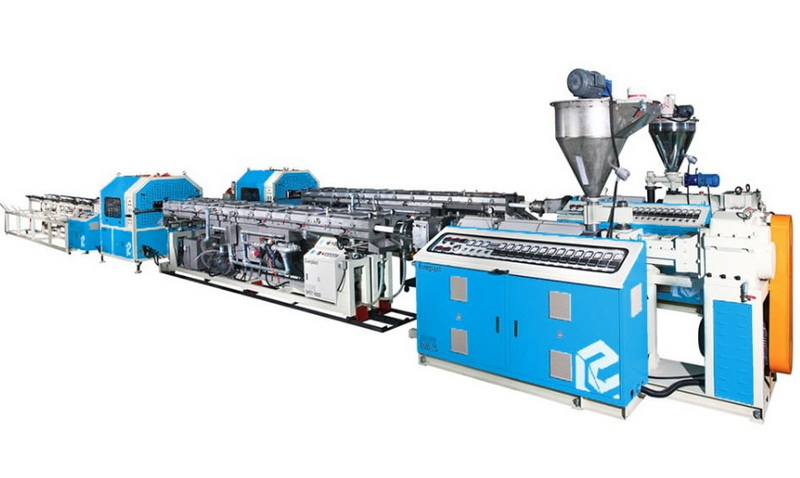

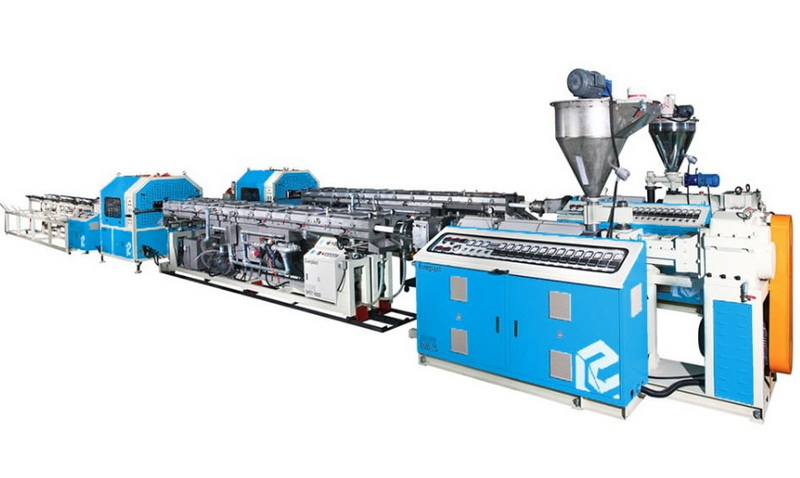

Yejing Machinery Manufacturing Co., Ltd is renowned for its high-quality aluminum extrusion machines. These machines are designed using the latest technology to ensure efficiency and reliability, making them ideal for industries like construction and aerospace.

2. Adex Technologies

Adex Technologies specializes in high-grade aluminum extrusion dies. Their products enhance press capabilities and increase die stability, making them suitable for the automotive and aerospace industries.

3. Gemini Group

The Gemini Group offers precision aluminum extrusion dies known for their durability and repeatability. Their products are used in manufacturing aluminum profiles for various industrial applications.

4. Diamond America

Diamond America designs and manufactures extrusion dies for both metal and plastic applications. Their customizable designs ensure high efficiency and adaptability across different industries.

5. Erd Metal

Erd Metal produces high-quality aluminum extrusion dies using advanced CAD/CAM software. Their dies are versatile and can be used for stamping, cutting, and forming aluminum extrusions.

Key Features of Trusted Suppliers

Trusted aluminum extrusion equipment suppliers typically offer:

- High-Quality Products: Advanced technology and materials ensure durability and precision.

- Customization Options: Ability to design and manufacture dies and equipment tailored to specific customer needs.

- Excellent Customer Service: Personalized support and quick response times enhance customer satisfaction.

- Reliability and Efficiency: Equipment designed to maximize production speed while minimizing waste.

Industry Trends and Innovations

As we approach 2025, the aluminum extrusion industry is undergoing significant technological advancements and responding to evolving market demands. Key developments include:

1. Industry Trends

- Lightweighting in Electric Vehicles (EVs): The rapid growth of the EV sector has intensified the demand for lightweight materials to enhance energy efficiency and extend driving range. Aluminum extrusions are increasingly utilized in vehicle bodies, chassis, and battery packs due to their excellent strength-to-weight ratio and corrosion resistance[1].

- Expansion in the Construction Sector: The global construction industry continues to drive demand for aluminum extrusions, particularly in windows, curtain walls, and structural frameworks. Projections indicate that by 2025, the market for aluminum in construction applications will reach $22.81 billion[1].

2. Technological Innovations

- Advancements in CNC Machining: Computer Numerical Control (CNC) machining technology is widely applied in aluminum processing, enabling high-precision and complex shape fabrication. Common CNC processes include milling, turning, drilling, and tapping[1].

- Surface Treatment Enhancements: Aluminum extrusions are increasingly subjected to advanced surface treatments such as anodizing, electrophoretic coating, and powder coating. Anodizing forms a dense oxide layer on the aluminum surface, enhancing corrosion resistance and hardness. Electrophoretic coating provides uniform coatings that improve UV resistance[1].

3. Market Dynamics

- Technological Upgrades: Manufacturers are investing in technological improvements to enhance product performance and expand application areas, catering to industries like automotive, medical devices, and electromechanical equipment.

- Environmental Considerations: With stricter environmental regulations, the aluminum extrusion industry is focusing on energy conservation and emission reduction. This includes adopting eco-friendly surface treatment agents and processes to minimize environmental impact.

Challenges Facing the Industry

The aluminum extrusion industry faces several challenges:

- Raw Material Constraints: Primary smelting capacity has declined over the past two decades, especially in North America and Europe. Older, inefficient smelters have been closed and have not been replaced. Primary ingot is now shipped to North America from Asia and the Middle East[2].

- Extrusion Billet Production: All North America cast houses are sold out for 2022 and likely for 2023. Additional casting capacity projects have been announced, but likely won't have an impact until 2024[2].

- Aluminum Extrusion Tooling: High demand and labor challenges have resulted in lead times of 4 to 5 weeks for the past 6 months, twice as long as in early 2019[2].

- Production Challenges: Demand is high across all major customers; Transportation, Building and Construction, Electrical, and Aerospace. Extrusion billet availability is scarce, and hiring, training, and retaining employees is an ongoing challenge[2].

Market Analysis

The global aluminum extrusion market is highly competitive, with numerous players offering a wide range of products. Prominent companies include Norsk Hydro ASA, Century Aluminum, Arconic, and Novelis[3]. The market is expanding due to its ability to create complex shapes and profiles, allowing designers and engineers to optimize design functions[7].

Future Trends

Looking ahead, the future of aluminum extrusion holds exciting possibilities, driven by technological advancements, sustainability considerations, and ever-evolving industry demands. The integration of artificial intelligence (AI) in aluminum extrusion has the potential to optimize the extrusion process, reduce material waste, and enhance product quality[4]. Additionally, AI offers precision control in aluminum extrusion by analyzing real-time data from the extrusion machinery, providing immediate adjustments to ensure the right specifications[7].

Conclusion

Choosing the right aluminum extrusion equipment supplier is crucial for ensuring efficiency, quality, and reliability in manufacturing processes. Companies like Yejing Machinery Manufacturing Co., Ltd, Adex Technologies, Gemini Group, Diamond America, and Erd Metal stand out for their expertise and commitment to customer satisfaction. As the industry continues to evolve, these suppliers will play a vital role in meeting the growing demands of various sectors.

FAQs

1. What is the role of aluminum extrusion equipment suppliers in the manufacturing process?

Aluminum extrusion equipment suppliers provide critical machinery and tools, such as dies and presses, necessary for transforming aluminum alloys into specific profiles. Their products are essential for industries like construction and automotive.

2. How do suppliers ensure the quality of aluminum extrusion equipment?

Suppliers ensure quality by using advanced materials, employing precise manufacturing techniques, and maintaining strict quality control measures. They also offer customization options to meet specific customer requirements.

3. What are the key challenges faced by aluminum extrusion equipment suppliers?

Challenges include high initial investment costs, the need for skilled personnel, and maintaining competitiveness in a rapidly evolving market. Suppliers must innovate and adapt to changing industry demands.

4. What are the benefits of working with trusted aluminum extrusion equipment suppliers?

Benefits include access to high-quality products, excellent customer service, and the ability to customize equipment to meet specific needs. Trusted suppliers also provide reliable and efficient solutions, enhancing overall manufacturing performance.

5. How do advancements in technology impact aluminum extrusion equipment suppliers?

Advancements in technology allow suppliers to develop more efficient and precise equipment. This leads to increased productivity, reduced waste, and improved product quality, making suppliers more competitive in the global market.

Citations:

[1] https://www.archalu.com/aluminum-extrusion-industry-trends-and-innovations-in-2025/

[2] https://profileprecisionextrusions.com/aluminum-extrusion-demand-challenges-in-2022/

[3] https://evolvebi.com/report/aluminum-extrusion-market-analysis/

[4] https://www.thebusinessresearchcompany.com/report/aluminum-extrusion-global-market-report

[5] https://www.sourcingallies.com/blog/aluminium-extrusion-suppliers-manufacturing-success

[6] https://www.verifiedmarketresearch.com/product/aluminium-extrusion-machines-market/

[7] https://www.precedenceresearch.com/aluminum-extrusion-market

[8] https://gloriaaluminium.com/blog/aluminium-extrusion-demand-challenges-in-2023/

[9] https://www.factmr.com/report/aluminum-extrusion-market

[10] https://blog.tbrc.info/2025/03/aluminum-extrusion-industry-2/

[11] https://www.atieuno.com/2023/10/09/aluminium-extrusion-manufacturers/

[12] https://www.grandviewresearch.com/industry-analysis/aluminum-extrusion-market

[13] https://www.technavio.com/report/aluminum-extrusion-market-industry-analysis

[14] https://www.harboraluminum.com/en/news/automotive-aluminum-extrusions-challenges-and-opportunities

[15] https://www.alliedmarketresearch.com/aluminum-extrusion-market-A09001

[16] https://www.researchandmarkets.com/reports/5685568/2025-aluminium-extrusion-market-outlook-report

[17] https://jmaluminium.com/manufacturers-of-aluminium-extrusion-obstacles-and-prospects/

[18] https://www.imarcgroup.com/aluminium-extrusion-market

[19] https://www.marketreportanalytics.com/reports/metal-extrusion-press-41242

[20] https://www.linkedin.com/pulse/future-aluminium-alloy-extrusion-industry-developments-challenges-5ppfe