Content Menu

● Understanding 80/20 Aluminum Extrusions

● Popular Applications of 80/20 Aluminum Extrusions

>> Industrial Automation

>> Workstations and Assembly Lines

>> Machine Guards and Safety Enclosures

>> Custom Racks and Shelving

>> Robotics and Automation Systems

>> Furniture Design

>> Prototyping and Product Development

>> Display and Exhibit Structures

>> Transportation and Logistics

>> Home Improvement Projects

● Benefits of Using 80/20 Aluminum Extrusions

● Conclusion

● Frequently Asked Questions

>> 1. What are 80/20 aluminum extrusions?

>> 2. What industries use 80/20 aluminum extrusions?

>> 3. Can I use 80/20 aluminum extrusions for DIY projects?

>> 4. How do I assemble 80/20 aluminum extrusions?

>> 5. Are 80/20 aluminum extrusions cost-effective?

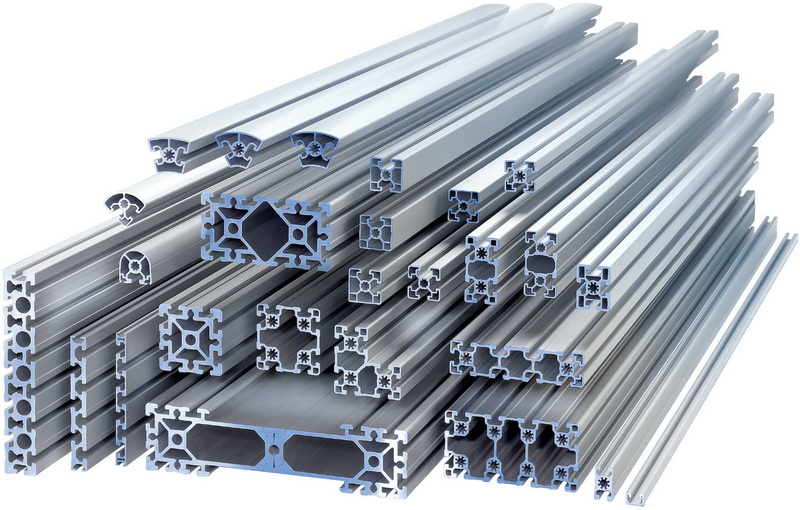

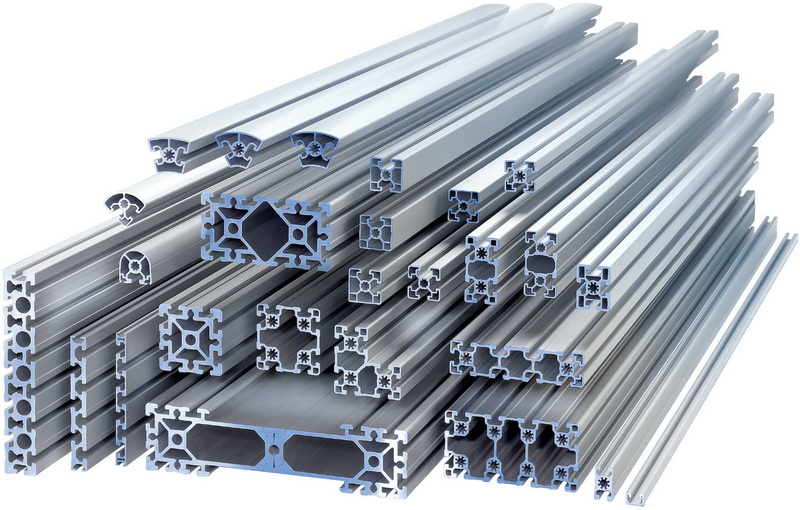

80/20 aluminum extrusions are a versatile and widely used material in various industries and applications. Known for their strength, lightweight nature, and modular design, these extrusions have become a go-to solution for engineers, designers, and DIY enthusiasts alike. In this article, we will explore the most popular applications for 80/20 aluminum extrusions, highlighting their benefits and showcasing how they can be utilized in different projects.

Understanding 80/20 Aluminum Extrusions

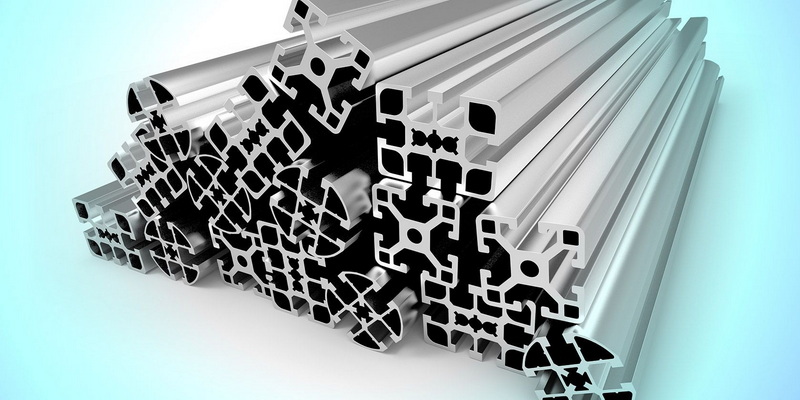

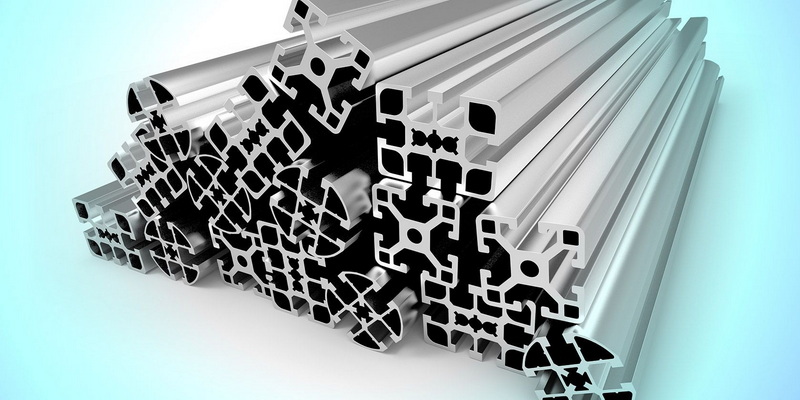

Before diving into specific applications, it's essential to understand what 80/20 aluminum extrusions are. The term "80/20" refers to the specific profile dimensions of the extrusions, which are typically 80mm by 20mm. These profiles feature a T-slot design, allowing for easy assembly and disassembly of structures without the need for specialized tools. This modularity makes them ideal for a wide range of applications, from industrial machinery to custom furniture.

Popular Applications of 80/20 Aluminum Extrusions

Industrial Automation

One of the most significant applications of 80/20 aluminum extrusions is in industrial automation. These extrusions are used to create frames for machines, conveyor systems, and robotic arms. Their lightweight yet sturdy nature allows for the construction of complex systems that can withstand heavy loads while remaining easy to modify and expand. The ability to quickly adapt and reconfigure systems is crucial in fast-paced manufacturing environments, where efficiency and flexibility are paramount.

Workstations and Assembly Lines

80/20 aluminum extrusions are commonly used to build custom workstations and assembly lines. The modular design allows for the creation of ergonomic workspaces tailored to specific tasks. Adjustable heights, integrated storage solutions, and customizable layouts are just a few benefits of using aluminum extrusions in workstation design. This adaptability not only enhances productivity but also improves worker comfort and safety, leading to better overall performance.

Machine Guards and Safety Enclosures

Safety is a top priority in any industrial setting. 80/20 aluminum extrusions can be used to construct machine guards and safety enclosures that protect workers from moving parts and hazardous materials. The T-slot design allows for easy integration of safety panels, doors, and access points, ensuring compliance with safety regulations. By using aluminum extrusions, companies can create robust safety solutions that are both effective and aesthetically pleasing.

Custom Racks and Shelving

In warehouses and storage facilities, 80/20 aluminum extrusions are often used to create custom racks and shelving systems. Their lightweight yet durable construction allows for the design of flexible storage solutions that can be easily adjusted as inventory needs change. This adaptability is crucial for optimizing space and improving efficiency. Custom racks can be designed to accommodate various products, ensuring that storage solutions are tailored to specific operational requirements.

Robotics and Automation Systems

The robotics industry heavily relies on 80/20 aluminum extrusions for building frames and structures. These extrusions provide the necessary strength and stability for robotic systems while allowing for easy modifications and upgrades. Whether it's a simple robotic arm or a complex automated assembly line, 80/20 extrusions are a popular choice. Their ability to support various components, such as motors and sensors, makes them ideal for creating sophisticated robotic solutions.

Furniture Design

Beyond industrial applications, 80/20 aluminum extrusions are increasingly being used in furniture design. Their modern aesthetic and structural integrity make them ideal for creating custom furniture pieces, such as desks, tables, and shelving units. The ability to easily modify designs allows for unique and personalized furniture solutions. Designers appreciate the clean lines and contemporary look that aluminum extrusions provide, making them a popular choice for both residential and commercial spaces.

Prototyping and Product Development

In product development and prototyping, speed and flexibility are crucial. 80/20 aluminum extrusions allow designers and engineers to quickly build prototypes of their products. The modular nature of these extrusions means that changes can be made on the fly, facilitating rapid iteration and testing. This capability is particularly valuable in industries where time-to-market is critical, as it enables teams to refine their designs efficiently.

Display and Exhibit Structures

Trade shows and exhibitions often require custom display structures to showcase products effectively. 80/20 aluminum extrusions can be used to create lightweight yet sturdy display stands, backdrops, and signage. Their modular design allows for easy assembly and disassembly, making them perfect for traveling exhibits. Companies can create eye-catching displays that are easy to transport and set up, enhancing their presence at events.

Transportation and Logistics

In the transportation sector, 80/20 aluminum extrusions are used to build custom trailers, racks, and storage solutions. Their lightweight nature helps reduce overall vehicle weight, improving fuel efficiency. Additionally, the ability to create custom solutions allows for optimized cargo space and organization. This is particularly important in logistics, where maximizing space can lead to significant cost savings.

Home Improvement Projects

DIY enthusiasts often turn to 80/20 aluminum extrusions for home improvement projects. Whether building custom shelving, creating a unique garden structure, or designing a home office, these extrusions provide the flexibility and strength needed for various applications. Their modern look also adds a contemporary touch to home designs. Homeowners appreciate the ease of assembly and the ability to create custom solutions that fit their specific needs.

Benefits of Using 80/20 Aluminum Extrusions

The popularity of 80/20 aluminum extrusions can be attributed to several key benefits:

- Modularity: The T-slot design allows for easy assembly and disassembly, making it simple to modify structures as needed.

- Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

- Durability: Aluminum is resistant to corrosion and wear, ensuring long-lasting performance in various environments.

- Versatility: 80/20 extrusions can be used in a wide range of applications, from industrial to residential projects.

- Cost-Effective: The ability to create custom solutions without the need for specialized tools can save time and money.

Conclusion

80/20 aluminum extrusions are a versatile and valuable resource in many industries. Their modular design, lightweight nature, and durability make them ideal for a wide range of applications, from industrial automation to custom furniture design. As technology continues to evolve, the uses for these extrusions will likely expand, further solidifying their place as a go-to solution for engineers, designers, and DIY enthusiasts alike.

Frequently Asked Questions

1. What are 80/20 aluminum extrusions?

80/20 aluminum extrusions are modular aluminum profiles designed with T-slots, allowing for easy assembly and customization in various applications.

2. What industries use 80/20 aluminum extrusions?

Industries such as manufacturing, robotics, furniture design, and transportation commonly use 80/20 aluminum extrusions for their versatility and strength.

3. Can I use 80/20 aluminum extrusions for DIY projects?

Yes, 80/20 aluminum extrusions are popular among DIY enthusiasts for creating custom furniture, storage solutions, and home improvement projects.

4. How do I assemble 80/20 aluminum extrusions?

Assembly is straightforward, requiring minimal tools. The T-slot design allows for easy connection of profiles using fasteners and brackets.

5. Are 80/20 aluminum extrusions cost-effective?

Yes, their modularity and ease of assembly can save time and labor costs, making them a cost-effective solution for many projects.