Content Menu

● Understanding Aluminum Extrusions

>> Benefits of Aluminum Extrusions

● Popular Aluminum Extrusion Profiles at Grainger

>> T-Slot Aluminum Extrusions

>> Rectangular and Square Tubes

>> Round Tubes

>> Angle Extrusions

>> Channel Extrusions

>> Custom Profiles

● Applications of Aluminum Extrusions

● Frequently Asked Questions

>> 1. What is the difference between T-slot and rectangular aluminum extrusions?

>> 2. Can aluminum extrusions be painted or anodized?

>> 3. What are the weight limits for aluminum extrusions?

>> 4. Are aluminum extrusions suitable for outdoor use?

>> 5. How do I choose the right aluminum extrusion for my project?

Understanding Aluminum Extrusions

Aluminum extrusions are a vital component in various industries, providing structural integrity and versatility in design. The process of aluminum extrusion involves shaping aluminum alloy into a desired cross-sectional profile. This begins with heating aluminum billets until they become malleable. The heated aluminum is then forced through a die, creating long lengths of the desired shape. This method allows for the production of complex shapes that are lightweight yet strong, making aluminum extrusions ideal for various applications.

Benefits of Aluminum Extrusions

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport. This property is particularly beneficial in industries where weight reduction is crucial, such as aerospace and automotive.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion. This makes aluminum extrusions suitable for outdoor applications and environments where exposure to moisture and chemicals is common.

3. Versatility: Aluminum extrusions can be customized to meet specific design requirements, making them suitable for a wide range of applications. This flexibility allows engineers and designers to create unique solutions tailored to their needs.

4. Recyclability: Aluminum is 100% recyclable without losing its properties, making it an environmentally friendly choice. The recycling process requires only 5% of the energy used to produce new aluminum, contributing to sustainability efforts.

5. Cost-Effective: The efficiency of the extrusion process can lead to lower production costs, especially for large quantities. This cost-effectiveness, combined with the durability of aluminum, makes it a popular choice for manufacturers.

Popular Aluminum Extrusion Profiles at Grainger

T-Slot Aluminum Extrusions

T-slot aluminum extrusions are among the most popular profiles available at Grainger. These profiles feature a T-shaped slot that allows for easy assembly and disassembly of structures. They are commonly used in building frames, workstations, and machine guards. The versatility of T-slot profiles makes them ideal for creating custom solutions in various industries.

T-slot extrusions are particularly favored in the manufacturing sector for building modular systems. Their design allows for the quick addition or removal of components, making it easy to adapt to changing needs. Additionally, T-slot profiles can be used in conjunction with a variety of accessories, such as brackets, connectors, and fasteners, further enhancing their functionality.

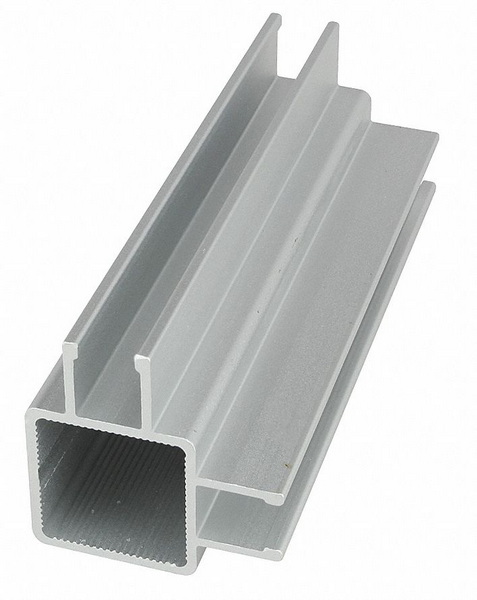

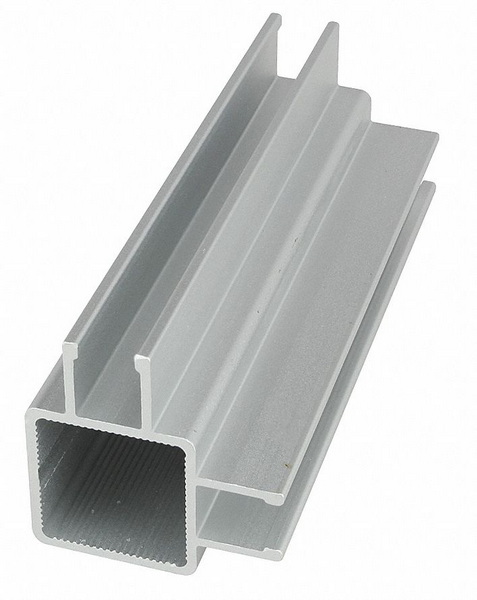

Rectangular and Square Tubes

Rectangular and square aluminum tubes are widely used for structural applications. Their uniform shape provides excellent strength and stability, making them suitable for frames, supports, and enclosures. Grainger offers a variety of sizes and wall thicknesses to meet different load requirements.

These profiles are often used in construction and manufacturing, where they serve as the backbone for various structures. Their rigidity and strength make them ideal for applications that require load-bearing capabilities, such as scaffolding and shelving systems.

Round Tubes

Round aluminum extrusions are commonly used in applications requiring a lightweight yet strong component. These profiles are often used in the construction of railings, furniture, and decorative elements. The smooth surface of round tubes also makes them ideal for aesthetic applications.

Round tubes are particularly popular in the furniture industry, where they are used to create modern and stylish designs. Their sleek appearance and lightweight nature make them an attractive choice for both residential and commercial furniture.

Angle Extrusions

Angle extrusions are L-shaped profiles that provide excellent support and stability. They are often used in brackets, frames, and structural supports. Grainger's angle extrusions come in various sizes and thicknesses, allowing for customization based on specific project needs.

These profiles are commonly used in construction and manufacturing applications, where they serve as corner supports or reinforcement for larger structures. Their design allows for easy integration into existing frameworks, making them a versatile choice for builders and engineers.

Channel Extrusions

Channel extrusions feature a U-shaped design that provides excellent load-bearing capabilities. These profiles are commonly used in construction, automotive, and manufacturing applications. The open design of channel extrusions allows for easy integration with other components.

Channel extrusions are often used in the construction of frames and supports, where their strength and stability are essential. They can also be used in the automotive industry for various applications, including chassis and body components.

Custom Profiles

Grainger also offers custom aluminum extrusion profiles tailored to specific project requirements. This flexibility allows engineers and designers to create unique solutions that meet their exact specifications. Custom profiles can be designed for various applications, from architectural elements to specialized machinery.

The ability to create custom profiles is a significant advantage in industries where standard shapes may not meet specific needs. Custom extrusions can be designed to accommodate unique load requirements, aesthetic preferences, or functional specifications, providing a tailored solution for any project.

Applications of Aluminum Extrusions

Aluminum extrusions are used in a wide range of industries, including:

- Construction: Used for window frames, doors, and structural supports. Aluminum's lightweight nature and corrosion resistance make it an ideal choice for building materials.

- Automotive: Employed in vehicle frames, body panels, and components. The use of aluminum in automotive applications helps reduce weight, improving fuel efficiency and performance.

- Aerospace: Utilized in aircraft structures and components due to their lightweight properties. Aluminum extrusions are essential in the aerospace industry, where every ounce counts.

- Electronics: Used in heat sinks, enclosures, and mounting brackets. The thermal conductivity of aluminum makes it an excellent choice for dissipating heat in electronic devices.

- Furniture: Commonly found in modern furniture designs, providing both strength and aesthetic appeal. Aluminum's versatility allows for innovative designs that are both functional and stylish.

Frequently Asked Questions

1. What is the difference between T-slot and rectangular aluminum extrusions?

T-slot extrusions have a slot that allows for easy assembly, while rectangular extrusions are solid and provide structural support. T-slot profiles are ideal for modular systems, while rectangular profiles are better suited for load-bearing applications.

2. Can aluminum extrusions be painted or anodized?

Yes, aluminum extrusions can be painted or anodized to enhance their appearance and corrosion resistance. Anodizing creates a durable finish that protects the aluminum and can be dyed in various colors.

3. What are the weight limits for aluminum extrusions?

The weight limits depend on the profile's dimensions and wall thickness. It's essential to consult specifications for each profile to determine its load-bearing capacity.

4. Are aluminum extrusions suitable for outdoor use?

Yes, aluminum extrusions are corrosion-resistant and can be used outdoors, especially when anodized or coated. Their durability makes them an excellent choice for outdoor applications.

5. How do I choose the right aluminum extrusion for my project?

Consider factors such as load requirements, environmental conditions, and design specifications when selecting an aluminum extrusion. It's also helpful to consult with suppliers or engineers for guidance on the best profile for your needs.