Content Menu

● Introduction

● Understanding 40x80 Aluminum Extrusion

● Benefits of Using 40x80 Aluminum Extrusion

>> Strength and Durability

>> Versatility in Applications

>> Ease of Assembly

● Common Applications of 40x80 Aluminum Extrusion

>> Industrial Equipment Frames

>> Custom Workstations

>> Conveyor Systems

>> Robotics and Automation

>> Architectural Applications

● Choosing the Right Supplier for Aluminum Extrusions

● Conclusion

● Related Questions

>> 1. What are the advantages of using aluminum extrusion over other materials?

>> 2. Can 40x80 aluminum extrusion be customized for specific projects?

>> 3. How does the T-slot design benefit assembly?

>> 4. What industries commonly use 40x80 aluminum extrusion?

>> 5. How do I choose a reliable supplier for aluminum extrusions?

Introduction

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. This process is widely used in various industries due to the material's lightweight, strength, and versatility. Among the many profiles available, the 40x80 aluminum extrusion, often referred to as 8040 aluminum extrusion, stands out for its unique dimensions and applications. This article explores the most common applications of 40x80 aluminum extrusion, highlighting its benefits and versatility in different sectors.

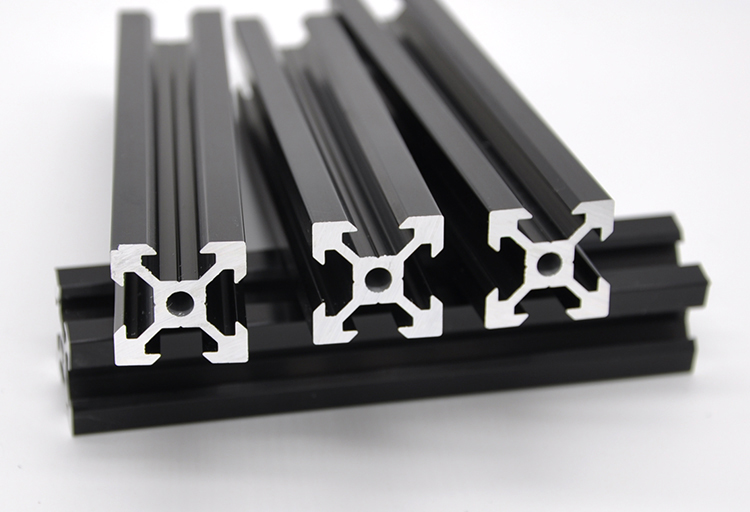

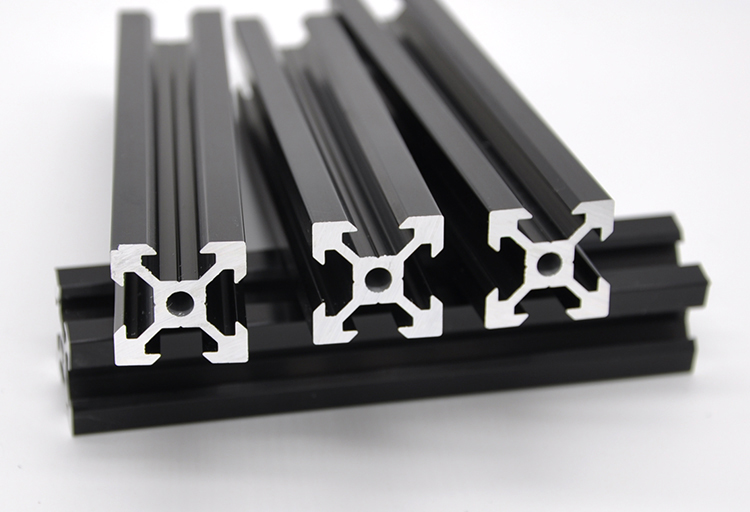

Understanding 40x80 Aluminum Extrusion

The 40x80 aluminum extrusion is characterized by its dimensions of 40mm by 80mm, making it a robust choice for various structural applications. This profile is typically made from 6063 aluminum alloy, known for its excellent corrosion resistance, good mechanical properties, and ease of fabrication. The T-slot design of the 8040 aluminum extrusion allows for easy assembly and disassembly, making it ideal for modular construction.

The versatility of the 40x80 aluminum extrusion is evident in its wide range of applications, from industrial machinery to architectural frameworks. Its strength-to-weight ratio makes it a preferred choice for engineers and designers looking to create lightweight yet durable structures.

Benefits of Using 40x80 Aluminum Extrusion

Strength and Durability

One of the primary benefits of using 40x80 aluminum extrusion is its strength and durability. The 6063 aluminum alloy used in its production provides excellent mechanical properties, making it suitable for heavy-duty applications. This profile can withstand significant loads while maintaining structural integrity, making it ideal for use in various environments, including industrial and outdoor settings.

Versatility in Applications

The versatility of 40x80 aluminum extrusion is one of its most significant advantages. It can be used in a wide range of applications, including:

- Industrial Machinery: The 8040 aluminum extrusion is commonly used in the construction of frames for industrial machines. Its strength and rigidity make it suitable for supporting heavy components and ensuring stability during operation.

- Workstations and Benches: Many manufacturers use 40x80 aluminum extrusion to create custom workstations and benches. The modular design allows for easy adjustments and reconfigurations, making it ideal for dynamic work environments.

- Automated Systems: In automation and robotics, the 40x80 aluminum extrusion is often used to build frames for robotic arms and conveyor systems. Its lightweight nature helps improve the efficiency of these systems while maintaining strength.

- Architectural Structures: The aesthetic appeal of aluminum makes it a popular choice in architectural applications. The 8040 aluminum extrusion can be used to create modern and sleek designs for buildings, facades, and interior structures.

Ease of Assembly

The T-slot design of the 40x80 aluminum extrusion allows for easy assembly and disassembly. This feature is particularly beneficial in applications where modifications or expansions are required. Users can quickly add or remove components without the need for specialized tools, making it a cost-effective solution for many projects.

Common Applications of 40x80 Aluminum Extrusion

Industrial Equipment Frames

One of the most common applications of 40x80 aluminum extrusion is in the construction of industrial equipment frames. These frames provide the necessary support for machinery and equipment, ensuring stability and safety during operation. The lightweight nature of aluminum allows for easier transportation and installation, reducing overall project costs.

Custom Workstations

In manufacturing and assembly environments, custom workstations built from 40x80 aluminum extrusion are prevalent. These workstations can be tailored to meet specific needs, such as height adjustments, storage solutions, and integrated tools. The modularity of the extrusion allows for easy reconfiguration, making it suitable for various tasks and workflows.

Conveyor Systems

Conveyor systems are essential in many industries for transporting materials and products. The 40x80 aluminum extrusion is often used to construct the frames and supports for these systems. Its strength ensures that the conveyor can handle heavy loads, while its lightweight nature allows for efficient movement and operation.

Robotics and Automation

The rise of automation in manufacturing has led to increased demand for lightweight and durable materials. The 40x80 aluminum extrusion is commonly used in the construction of robotic arms and automated systems. Its ability to withstand dynamic loads while remaining lightweight makes it an ideal choice for these applications.

Architectural Applications

In architecture, the aesthetic qualities of aluminum make it a popular choice for various applications. The 40x80 aluminum extrusion can be used in the construction of modern facades, window frames, and interior structures. Its versatility allows architects to create innovative designs while benefiting from the material's durability and low maintenance requirements.

Choosing the Right Supplier for Aluminum Extrusions

When selecting a supplier for 40x80 aluminum extrusion, it is essential to consider several factors. Quality is paramount; ensure that the supplier provides high-quality aluminum that meets industry standards. Additionally, look for suppliers that offer customization options, as this can be crucial for specific project requirements.

Another important aspect is the supplier's ability to provide timely delivery. Delays in receiving materials can significantly impact project timelines, so choose a supplier known for reliability. Finally, consider the supplier's customer service; a responsive and knowledgeable team can make the procurement process smoother and more efficient.

Conclusion

The 40x80 aluminum extrusion, or 8040 aluminum extrusion, is a versatile and robust solution for various applications across multiple industries. Its strength, durability, and ease of assembly make it an ideal choice for everything from industrial machinery to architectural designs. As industries continue to evolve, the demand for lightweight and durable materials like 40x80 aluminum extrusion will only increase, solidifying its place as a staple in modern manufacturing and construction.

Related Questions

1. What are the advantages of using aluminum extrusion over other materials?

Aluminum extrusion offers several advantages, including a high strength-to-weight ratio, excellent corrosion resistance, and ease of fabrication. These properties make it suitable for a wide range of applications, from structural components to decorative elements.

2. Can 40x80 aluminum extrusion be customized for specific projects?

Yes, 40x80 aluminum extrusion can be customized to meet specific project requirements. Many suppliers offer various lengths, finishes, and additional features to tailor the extrusion to your needs.

3. How does the T-slot design benefit assembly?

The T-slot design allows for easy assembly and disassembly of components without the need for specialized tools. This modularity enables quick adjustments and reconfigurations, making it ideal for dynamic work environments.

4. What industries commonly use 40x80 aluminum extrusion?

Industries such as manufacturing, automation, construction, and architecture commonly use 40x80 aluminum extrusion. Its versatility makes it suitable for various applications within these sectors.

5. How do I choose a reliable supplier for aluminum extrusions?

When choosing a supplier, consider factors such as product quality, customization options, delivery reliability, and customer service. Researching reviews and testimonials can also help identify reputable suppliers.