Content Menu

● Understanding Aluminum Extrusion

>> Benefits of Aluminum Extrusion

● Common Applications of 40x20 Aluminum Extrusion

>> 1. Construction and Architecture

>> 2. Automotive Industry

>> 3. Industrial Applications

>> 4. Furniture and Interior Design

>> 5. Electronics and Electrical Applications

>> 6. DIY Projects and Hobbyist Applications

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. What are the benefits of using aluminum extrusions?

>> 3. In which industries is 40x20 aluminum extrusion commonly used?

>> 4. Can aluminum extrusions be customized?

>> 5. How do I cut and assemble aluminum extrusions?

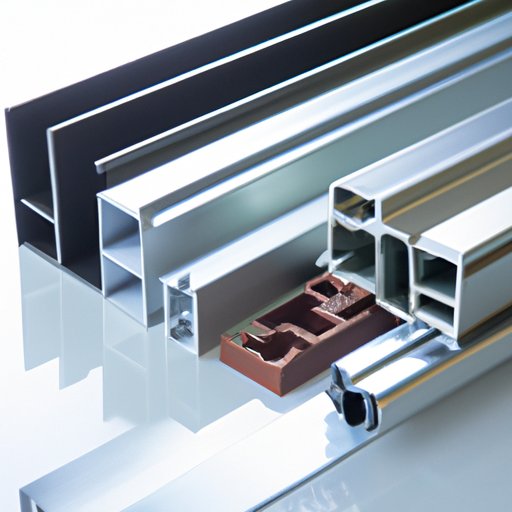

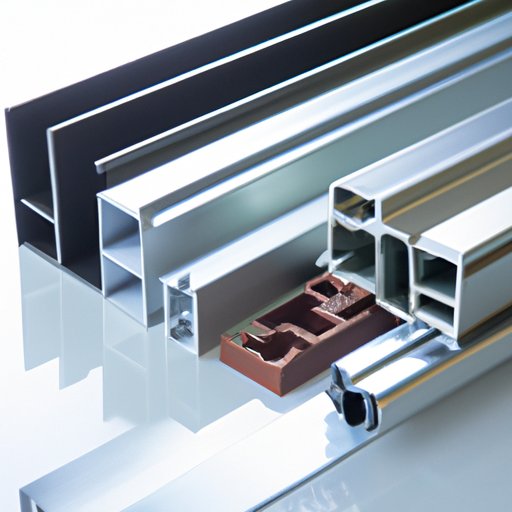

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile. The versatility of aluminum makes it a popular choice in various industries, and one of the most commonly used profiles is the 40x20 aluminum extrusion. This article explores the most common applications of 40x20 aluminum extrusion, highlighting its benefits, uses, and the reasons behind its popularity.

Understanding Aluminum Extrusion

Before diving into the applications, it's essential to understand what aluminum extrusion is. The process involves forcing aluminum alloy through a die to create a specific shape. This method allows for the production of complex shapes with high precision and excellent surface finish. The resulting extrusions can be cut to length, machined, and assembled into various structures.

Benefits of Aluminum Extrusion

1. Lightweight: Aluminum is significantly lighter than steel, making it easier to handle and transport.

2. Corrosion Resistance: Aluminum naturally forms a protective oxide layer, which helps resist corrosion.

3. Strength: Despite its lightweight nature, aluminum can be engineered to provide high strength-to-weight ratios.

4. Versatility: Aluminum extrusions can be used in a wide range of applications, from structural components to decorative elements.

5. Recyclability: Aluminum is 100% recyclable without loss of quality, making it an environmentally friendly choice.

Common Applications of 40x20 Aluminum Extrusion

1. Construction and Architecture

One of the primary applications of 40x20 aluminum extrusion is in the construction and architectural sectors. It is used for:

- Window Frames: The lightweight and durable nature of aluminum makes it ideal for window frames, providing structural integrity while allowing for large glass panels.

- Doors: Aluminum extrusions are commonly used in door frames, offering a modern aesthetic and excellent durability.

- Curtain Walls: In commercial buildings, 40x20 aluminum extrusions are used to create curtain walls, which are non-structural cladding systems that provide weather protection and aesthetic appeal.

- Roofing Systems: Aluminum extrusions are also utilized in roofing systems, where they can support panels and provide a lightweight yet strong framework.

The use of aluminum in construction not only enhances the aesthetic appeal of buildings but also contributes to energy efficiency by allowing for better insulation and reduced energy costs.

2. Automotive Industry

The automotive industry has increasingly adopted aluminum extrusions due to their lightweight properties, which contribute to fuel efficiency. Applications include:

- Chassis Components: 40x20 aluminum extrusions are used in the construction of vehicle chassis, providing strength while reducing weight.

- Heat Sinks: Aluminum's excellent thermal conductivity makes it suitable for heat sinks in electric vehicles and other automotive applications.

- Structural Supports: Many vehicles utilize aluminum extrusions for structural supports, enhancing safety without adding significant weight.

- Body Panels: Aluminum extrusions are also used in body panels, which help reduce the overall weight of the vehicle, improving performance and fuel economy.

As the automotive industry continues to focus on sustainability and efficiency, the demand for aluminum extrusions is expected to grow, particularly in electric and hybrid vehicles.

3. Industrial Applications

In industrial settings, 40x20 aluminum extrusions are utilized for various purposes:

- Machine Frames: Many machines are built using aluminum extrusions, providing a lightweight yet sturdy framework.

- Conveyor Systems: Aluminum extrusions are often used in conveyor systems, allowing for easy assembly and modification.

- Workstations: Custom workstations can be designed using 40x20 aluminum extrusions, offering flexibility in layout and design.

- Safety Guards: Aluminum extrusions are also used to create safety guards and barriers in industrial environments, ensuring worker safety while maintaining visibility.

The adaptability of aluminum extrusions in industrial applications allows for efficient production processes and enhanced workplace safety.

4. Furniture and Interior Design

The furniture industry has embraced aluminum extrusions for their modern look and durability. Common applications include:

- Tables and Desks: Aluminum frames are used in various furniture designs, providing a sleek and contemporary appearance.

- Shelving Units: 40x20 aluminum extrusions are often used in shelving systems, offering strength and stability.

- Partitions: In office environments, aluminum extrusions can be used to create partitions, allowing for flexible workspace configurations.

- Display Stands: Retail environments frequently use aluminum extrusions for display stands, as they can be easily customized to fit different products and layouts.

The aesthetic appeal and functional benefits of aluminum furniture make it a popular choice in both residential and commercial settings.

5. Electronics and Electrical Applications

Aluminum extrusions are widely used in the electronics industry due to their thermal properties and lightweight nature:

- Heat Sinks: As mentioned earlier, aluminum is an excellent material for heat sinks in electronic devices, helping to dissipate heat effectively.

- Enclosures: Many electronic devices are housed in aluminum extrusions, providing protection while allowing for efficient heat dissipation.

- Mounting Frames: Aluminum extrusions are often used to create mounting frames for various electronic components, ensuring stability and ease of assembly.

- Cable Management Systems: Aluminum extrusions can also be used in cable management systems, helping to organize and protect wiring in electronic installations.

The use of aluminum in electronics not only enhances performance but also contributes to the longevity of devices.

6. DIY Projects and Hobbyist Applications

The versatility of 40x20 aluminum extrusion makes it a favorite among DIY enthusiasts and hobbyists. Applications include:

- Robotics: Many hobbyists use aluminum extrusions to build robot frames due to their lightweight and customizable nature.

- Model Building: Aluminum extrusions can be used in model building, providing a sturdy framework for various structures.

- Custom Projects: The ease of assembly and modification makes aluminum extrusions ideal for custom projects, from furniture to display stands.

- Home Automation: DIY enthusiasts often use aluminum extrusions to create frames for home automation systems, allowing for easy integration of technology into their living spaces.

The ability to easily modify and adapt aluminum extrusions makes them an excellent choice for creative projects.

Conclusion

The 40x20 aluminum extrusion is a versatile and widely used profile in various industries. Its lightweight, strength, and corrosion resistance make it an ideal choice for applications ranging from construction and automotive to electronics and DIY projects. As industries continue to seek lightweight and durable materials, the demand for aluminum extrusions is expected to grow.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloy into a desired cross-sectional profile by forcing it through a die.

2. What are the benefits of using aluminum extrusions?

Benefits include lightweight, corrosion resistance, strength, versatility, and recyclability.

3. In which industries is 40x20 aluminum extrusion commonly used?

It is commonly used in construction, automotive, industrial applications, furniture design, electronics, and DIY projects.

4. Can aluminum extrusions be customized?

Yes, aluminum extrusions can be customized in terms of shape, size, and finish to meet specific project requirements.

5. How do I cut and assemble aluminum extrusions?

Aluminum extrusions can be cut using standard cutting tools, and they can be assembled using brackets, screws, or welding, depending on the application.