Content Menu

● Overview of Aluminum Extrusion

● Key Players in the UAE Aluminum Extrusion Market

>> Innovations and Trends in Aluminum Extrusion

>> Applications of Aluminum Extrusions

● Economic Impact of Aluminum Extrusion Industry

● Challenges Facing Aluminum Extrusion Companies

● Conclusion

● Frequently Asked Questions

>> 1. What is aluminum extrusion?

>> 2. Why is aluminum preferred for extrusions?

>> 3. What industries utilize aluminum extrusions?

>> 4. How do I choose an aluminum extrusion company?

>> 5. What are the benefits of using recycled aluminum?

The aluminum extrusion industry in the United Arab Emirates (UAE) has grown significantly over the years, becoming a vital sector in the region's economy. With the increasing demand for aluminum profiles across various industries, several companies have emerged as leaders in this field. This article explores the top aluminum extrusion companies in the UAE, their capabilities, and contributions to the industry.

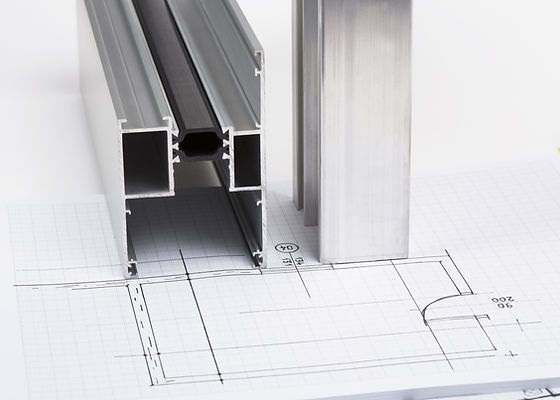

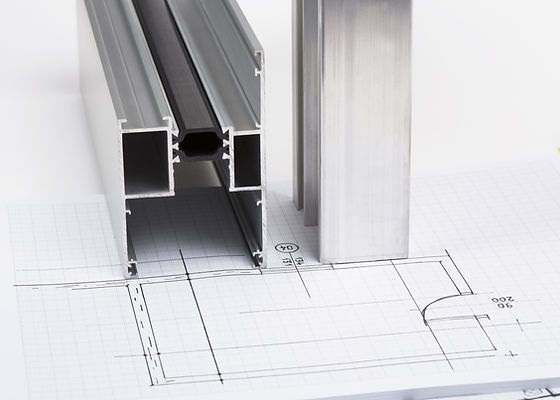

Overview of Aluminum Extrusion

Aluminum extrusion is a manufacturing process that involves forcing aluminum alloy through a die to create objects with a fixed cross-sectional profile. This process is widely utilized in numerous applications, including construction, automotive, aerospace, and consumer goods. The versatility of aluminum makes it an ideal choice for various products due to its lightweight, strength, and resistance to corrosion.

The process of aluminum extrusion can be divided into two main types: direct extrusion and indirect extrusion. In direct extrusion, the aluminum billet is heated and then pushed through a die using a ram. In contrast, indirect extrusion involves pulling the die through the billet. Each method has its advantages, with direct extrusion being more common due to its efficiency and cost-effectiveness.

Key Players in the UAE Aluminum Extrusion Market

The UAE hosts several prominent aluminum extrusion companies that cater to both local and international markets. Below are some of the leading players:

1. Emirates Extrusion Factory LLC

Established in 1993 in Ajman, Emirates Extrusion Factory is recognized for its innovative approaches and high-quality products. The company operates two extrusion presses with a total production capacity of approximately 13,800 tonnes per year. Emirates Extrusion specializes in producing a wide range of aluminum profiles for various applications, including architectural and industrial uses.

The company also emphasizes sustainability by implementing environmentally friendly practices in its operations. This includes recycling scrap aluminum and reducing waste during production processes.

2. Gulf Extrusions Co. LLC

Gulf Extrusions, based in Dubai, is one of the largest aluminum extrusion plants in the Middle East. Part of the Al Ghurair Group, it has an annual production capacity exceeding 60,000 tonnes. Gulf Extrusions offers a diverse range of products including standard and custom profiles, catering to various sectors such as construction and automotive.

In addition to its extensive product range, Gulf Extrusions is known for its commitment to quality assurance and customer satisfaction. The company invests heavily in research and development to innovate new products that meet changing market demands.

3. Aluminium Products Company (ALUPCO)

Founded in 1975, ALUPCO is considered the largest extrusion company in the Middle East and North Africa (MENA) region. With a production capacity exceeding 85,000 tonnes per year, ALUPCO serves clients across various industries with a wide array of aluminum profiles and systems designed for energy efficiency.

ALUPCO's commitment to quality is evidenced by its ISO certifications and adherence to international standards. The company also focuses on developing energy-efficient solutions that help reduce environmental impact while providing high-performance products.

4. Taweelah Aluminium Extrusion Company LLC (TALEX)

Located in Abu Dhabi's Khalifa Industrial Zone (KIZAD), TALEX is known for its advanced manufacturing capabilities. A joint venture between SENAAT and Gulf Extrusions, TALEX has a production capacity of 50,000 tonnes annually and focuses on high-quality aluminum profiles for construction and industrial applications.

TALEX aims to leverage cutting-edge technology to enhance productivity while maintaining strict quality control measures throughout its production processes.

5. National Aluminium Products Company (NAPCO)

Established in 1984, NAPCO has become a significant player in the GCC market with a production capacity of 42,000 tonnes per year. The company is known for its commitment to quality and innovation, offering a variety of extruded aluminum profiles that meet modern design specifications.

NAPCO also emphasizes customer service by providing tailored solutions that meet specific client requirements while ensuring timely delivery of products.

Innovations and Trends in Aluminum Extrusion

The aluminum extrusion industry is characterized by continuous innovation aimed at improving production efficiency and product quality. Companies are increasingly investing in advanced technologies such as automated extrusion processes and high-precision machining to enhance their offerings.

Additionally, there is a growing trend towards sustainability within the industry. Many companies are adopting eco-friendly practices by utilizing recycled materials and implementing energy-efficient manufacturing processes.

One notable trend is the use of 3D printing technology alongside traditional extrusion methods to create complex shapes that were previously difficult or impossible to manufacture using standard techniques. This innovation allows for greater design flexibility and faster prototyping.

Applications of Aluminum Extrusions

Aluminum extrusions find applications across multiple sectors due to their adaptability:

- Construction: Used for window frames, doors, curtain walls, structural components, roofing systems, and decorative elements.

- Automotive: Lightweight components that improve fuel efficiency without compromising safety; used in chassis parts, engine components, heat exchangers, and interior fittings.

- Aerospace: Critical parts that require high strength-to-weight ratios; used in aircraft frames, wing structures, fuselage components.

- Consumer Goods: Products ranging from furniture (like tables and chairs) to electronic housings (like laptops and smartphones).

Economic Impact of Aluminum Extrusion Industry

The aluminum extrusion sector significantly contributes to the UAE's economy by creating jobs and fostering technological advancements. As one of the fastest-growing industries within the region's manufacturing sector, it attracts foreign investment while supporting local businesses through supply chain partnerships.

Moreover, as global demand for lightweight materials increases—especially in automotive and aerospace industries—the UAE's strategic location allows it to serve as an export hub for aluminum products throughout Asia and Europe.

Challenges Facing Aluminum Extrusion Companies

Despite its growth potential, the aluminum extrusion industry faces several challenges:

- Raw Material Costs: Fluctuations in global aluminum prices can impact profitability for manufacturers.

- Competition: The market has become increasingly competitive with new entrants seeking to capture market share.

- Technological Advancements: Keeping up with rapid technological changes requires continuous investment in new equipment and training for employees.

- Sustainability Pressures: There is an increasing demand from consumers for environmentally friendly products which requires companies to adapt their practices accordingly.

Conclusion

The aluminum extrusion industry in the UAE plays a crucial role in supporting various sectors through innovative products and sustainable practices. Companies like Emirates Extrusion Factory, Gulf Extrusions, ALUPCO, TALEX, and NAPCO lead the market with their extensive capabilities and commitment to quality.

As demand continues to grow for aluminum products across different industries—driven by trends toward lightweight materials and sustainable practices—these companies are well-positioned to meet market needs while contributing positively to economic development within the region.

Frequently Asked Questions

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process where aluminum alloy is forced through a die to create objects with specific cross-sectional profiles used in various applications.

2. Why is aluminum preferred for extrusions?

Aluminum is lightweight yet strong; it resists corrosion; it is malleable for complex shapes; it can be fully recycled without losing its properties.

3. What industries utilize aluminum extrusions?

Industries such as construction, automotive, aerospace, electronics, consumer goods extensively use aluminum extrusions for their products.

4. How do I choose an aluminum extrusion company?

Consider factors such as production capacity; quality certifications (like ISO); range of products offered; customer service reputation; technological capabilities when selecting an aluminum extrusion company.

5. What are the benefits of using recycled aluminum?

Using recycled aluminum reduces energy consumption during production compared to primary aluminum manufacturing; it minimizes environmental impact while maintaining material integrity.