Content Menu

● Understanding Aluminum Extrusion

● Current Trends in Aluminum Extrusion

>> 1. Sustainable Practices

>> 2. Technological Innovations

>> 3. Customization and Flexibility

>> 4. Growth in Automotive Applications

>> 5. Expansion of Market Applications

● Key Players in California's Aluminum Extrusion Market

● Challenges Facing the Industry

● Future Outlook

● Conclusion

● Frequently Asked Questions (FAQ)

>> 1. What is aluminum extrusion?

>> 2. Why is sustainability important in aluminum extrusion?

>> 3. How does technology influence aluminum extrusion?

>> 4. What industries benefit from aluminum extrusions?

>> 5. What challenges does the aluminum extrusion industry face?

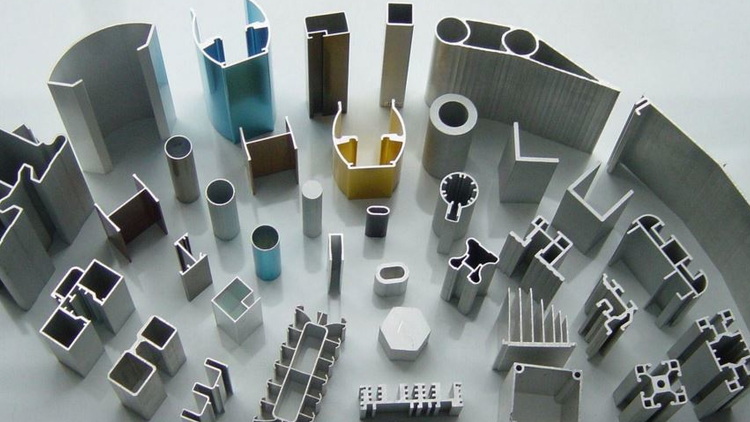

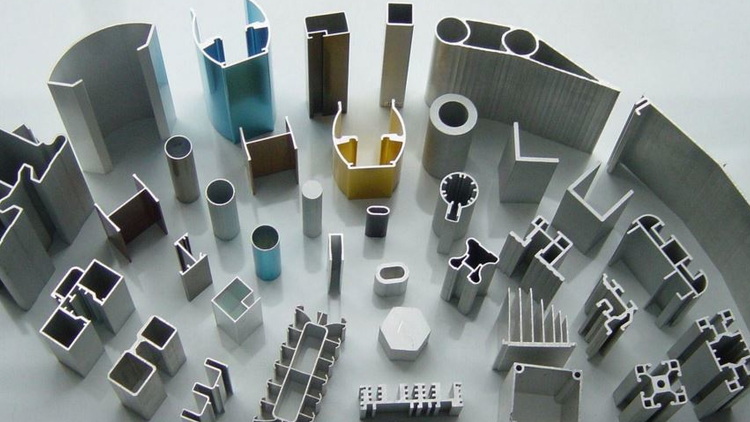

Aluminum extrusion is a vital manufacturing process that shapes aluminum alloys into various profiles for numerous applications, including construction, automotive, and consumer goods. As California's economy continues to evolve, the aluminum extrusion industry is witnessing significant trends driven by technological advancements, sustainability efforts, and market demands. This article explores the latest trends in aluminum extrusion in California, highlighting innovations, market dynamics, and future prospects.

Understanding Aluminum Extrusion

Aluminum extrusion involves forcing aluminum alloy material through a die with a specific cross-sectional profile. This process creates lightweight and durable components suitable for various applications. The extrusion process begins with heating an aluminum billet to make it malleable. A powerful ram then pushes the heated aluminum through the die, shaping it into the desired profile. The extruded material is subsequently cooled and cut to length for further processing or use.

Current Trends in Aluminum Extrusion

1. Sustainable Practices

The demand for sustainable construction practices is reshaping the aluminum extrusion landscape in California. Aluminum is favored for its lightweight properties and recyclability, making it an ideal choice for eco-friendly building materials. Many manufacturers are adopting green practices by utilizing recycled aluminum and energy-efficient processes to reduce their carbon footprint. This shift aligns with California's stringent environmental regulations and the growing emphasis on sustainability across industries.

In recent years, advancements in green practices have led to the development of energy-efficient extrusion processes that significantly lower the carbon footprint of aluminum production. Companies are increasingly investing in technologies that allow them to recycle aluminum scrap effectively, which not only conserves resources but also reduces waste.

2. Technological Innovations

Technological advancements are revolutionizing the aluminum extrusion process. Innovations such as precision extrusion techniques allow for more complex designs while improving efficiency and reducing waste. Additionally, the integration of artificial intelligence (AI) in extrusion processes enhances quality control by enabling real-time monitoring and adjustments during production. These technologies not only improve product quality but also streamline operations, leading to cost savings for manufacturers.

Recent developments include:

- Nano-coating technologies that enhance durability by providing an extra layer of protection against corrosion and abrasion.

- AI-powered precision control solutions that analyze real-time data from machinery to ensure each profile adheres to exact specifications.

- Smart extrusion lines integrated with IoT technology for comprehensive monitoring and control of production processes.

These innovations help manufacturers optimize production levels while maintaining high-quality standards.

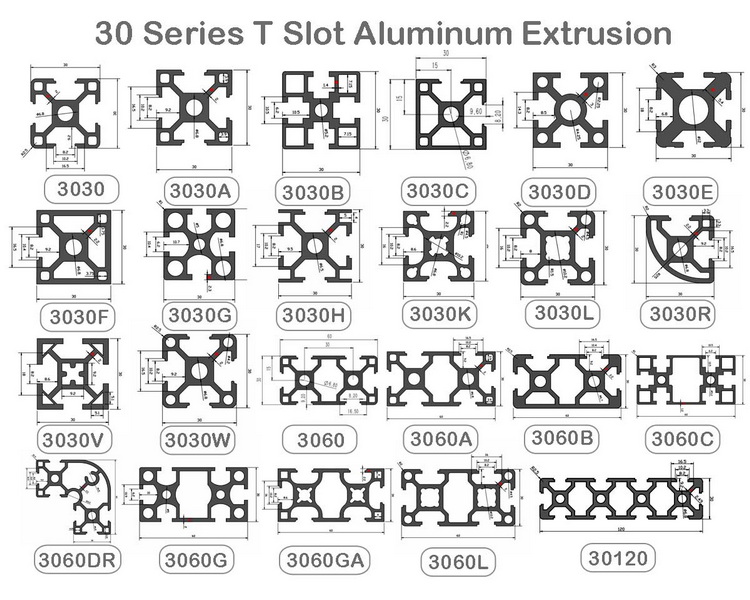

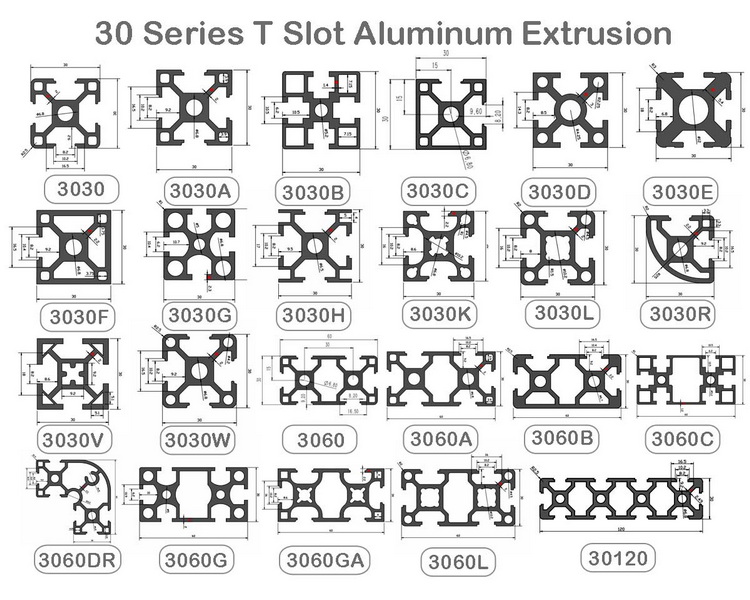

3. Customization and Flexibility

As industries demand more customized solutions, aluminum extrusion companies in California are increasingly focusing on providing tailored products. Manufacturers are investing in advanced machinery that allows for flexible production runs and rapid prototyping. This capability enables them to respond quickly to market needs and deliver unique solutions that meet specific customer requirements.

The growing trend towards customization is evident across various sectors:

- In automotive applications, manufacturers are producing lightweight components tailored to specific vehicle designs.

- In building and construction, custom extrusions are being used for architectural features that require unique shapes and sizes.

This flexibility not only enhances customer satisfaction but also opens new revenue streams for manufacturers.

4. Growth in Automotive Applications

The automotive sector is a significant driver of growth for aluminum extrusion in California. With the industry's ongoing shift towards lightweight materials to improve fuel efficiency and reduce emissions, aluminum extrusions are becoming increasingly popular in vehicle design. This trend is particularly evident in electric vehicles (EVs), where weight reduction is critical for maximizing battery performance.

Aluminum's properties make it an ideal material for automotive applications:

- It is corrosion-resistant and can absorb twice the energy of steel at the same weight.

- Body panels made from aluminum can be thicker yet lighter than steel, providing better dent resistance.

Major automotive manufacturers are increasingly incorporating aluminum extrusions into their designs to enhance performance while complying with stringent emissions regulations set by agencies like the California Air Resource Board (CARB) and the National Highway Traffic Safety Administration (NHTSA).

5. Expansion of Market Applications

Aluminum extrusions are finding new applications beyond traditional sectors like construction and automotive. Industries such as renewable energy, telecommunications, and consumer goods are increasingly utilizing aluminum profiles due to their strength, durability, and versatility. For instance, solar panel frames and structural components for wind turbines are now commonly made from extruded aluminum.

The versatility of aluminum allows it to be used in various products:

- Consumer products: From kitchen appliances to office furniture, extruded profiles are widely used due to their lightweight nature.

- Rail transportation: Aluminum extrusions reduce weight in train cars while increasing load capacity and fuel efficiency.

These expanding applications highlight the adaptability of aluminum as a material suited for modern manufacturing needs.

Key Players in California's Aluminum Extrusion Market

Several companies are at the forefront of the aluminum extrusion industry in California:

- Zetwerk: Based in San Francisco, Zetwerk specializes in custom aluminum extrusions and offers a range of services including CNC machining and powder coating.

- Hydro Extrusion: With facilities across California, Hydro provides comprehensive solutions for custom extrusions while emphasizing quality control and sustainability.

- Kaiser Aluminum: A major player with a strong presence in California, Kaiser Aluminum focuses on innovative products for various sectors including aerospace and automotive.

These companies are leveraging new technologies and sustainable practices to maintain their competitive edge in a rapidly evolving market.

Challenges Facing the Industry

Despite its growth potential, the aluminum extrusion industry in California faces several challenges:

- Supply Chain Disruptions: Global supply chain issues have impacted raw material availability and pricing, affecting production timelines.

- Competition from Alternative Materials: While aluminum is favored for many applications, competition from other materials such as carbon fiber and advanced composites poses a threat.

- Regulatory Compliance: Adhering to environmental regulations can be challenging for manufacturers looking to implement sustainable practices without incurring significant costs.

Additionally, price volatility related to raw materials can hinder market growth as fluctuations affect profit margins for manufacturers.

Future Outlook

The future of aluminum extrusion in California looks promising as demand continues to rise across various sectors. With ongoing investments in technology and sustainability initiatives, manufacturers are well-positioned to capitalize on emerging opportunities. As industries increasingly prioritize lightweight materials and eco-friendly solutions, aluminum extrusions will play a crucial role in shaping the future of manufacturing.

Market forecasts indicate substantial growth potential:

- The U.S. aluminum extrusion market was valued at approximately USD 6.78 billion in 2023.

- It is projected to grow at a compound annual growth rate (CAGR) of 7% from 2024 to 2030.

This growth trajectory reflects strong demand across key sectors like automotive and construction while highlighting the importance of innovation within the industry.

Conclusion

In conclusion, the latest trends in aluminum extrusion in California reflect a dynamic industry poised for growth driven by sustainability efforts, technological innovations, customization demands, and expanding market applications. Manufacturers who adapt to these trends will not only enhance their competitiveness but also contribute to a more sustainable future. As we look ahead, it is clear that aluminum extrusion will continue to play an integral role across various industries as they strive towards efficiency, performance improvement, and environmental responsibility.

Frequently Asked Questions (FAQ)

1. What is aluminum extrusion?

Aluminum extrusion is a manufacturing process that shapes aluminum alloys by forcing them through a die with a specific cross-section to create long profiles used in various applications.

2. Why is sustainability important in aluminum extrusion?

Sustainability is crucial because it reduces environmental impact through recycling efforts and energy-efficient processes that align with regulatory standards and consumer preferences.

3. How does technology influence aluminum extrusion?

Technological advancements enhance production efficiency, improve product quality through real-time monitoring, and allow for more complex designs via precision extrusion techniques.

4. What industries benefit from aluminum extrusions?

Industries such as construction, automotive, renewable energy, telecommunications, and consumer goods benefit significantly from using lightweight and durable aluminum extrusions.

5. What challenges does the aluminum extrusion industry face?

Challenges include supply chain disruptions affecting raw material availability, competition from alternative materials, price volatility affecting profit margins, and navigating regulatory compliance related to environmental standards.