Content Menu

● Introduction to Extrusion Machinery

>> Key Components of Extrusion Machines

● Latest Trends in Extrusion Machinery

>> 1. Technological Advancements

>> 2. Sustainability and Recycling

>> 3. Integration with 3D Printing

>> 4. Industry 4.0 Technologies

>> 5. Energy Efficiency and Cost Reduction

● Market Growth and Outlook

>> Key Players and Innovations

● Regional Market Analysis

>> Impact of Global Events

● Future Developments

● Conclusion

● FAQ

>> 1. What role does AI play in extrusion technology?

>> 2. How is sustainability impacting extrusion processes?

>> 3. What are the benefits of integrating 3D printing with extrusion?

>> 4. How do Industry 4.0 technologies enhance extrusion processes?

>> 5. What drives the growth of the extrusion machinery market?

The extrusion machinery market is witnessing significant growth, driven by technological advancements, increasing demand for extruded products, and a focus on sustainability. Manufacturers of extrusion machinery are at the forefront of this evolution, introducing innovative solutions that enhance efficiency, precision, and environmental responsibility. This article explores the latest trends in the industry, highlighting key developments and their implications for future manufacturing processes.

Introduction to Extrusion Machinery

Extrusion machinery is used to shape materials, typically plastics or metals, by forcing them through a die to create specific profiles or forms. This process is crucial in various industries, including construction, packaging, and automotive, where extruded products are valued for their durability, lightweight nature, and cost-effectiveness.

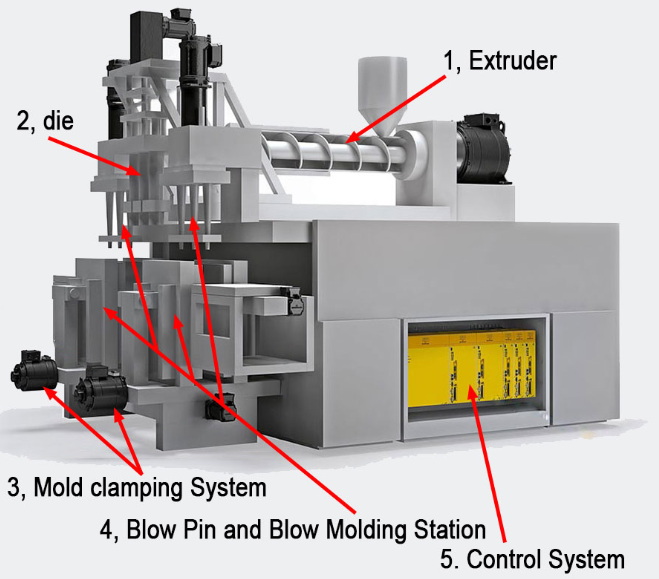

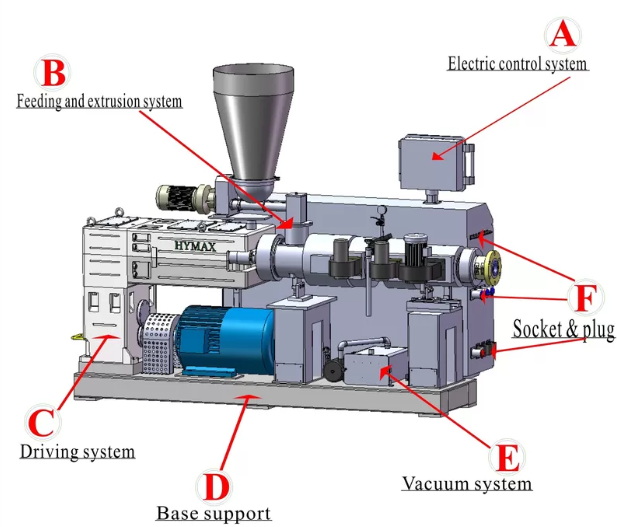

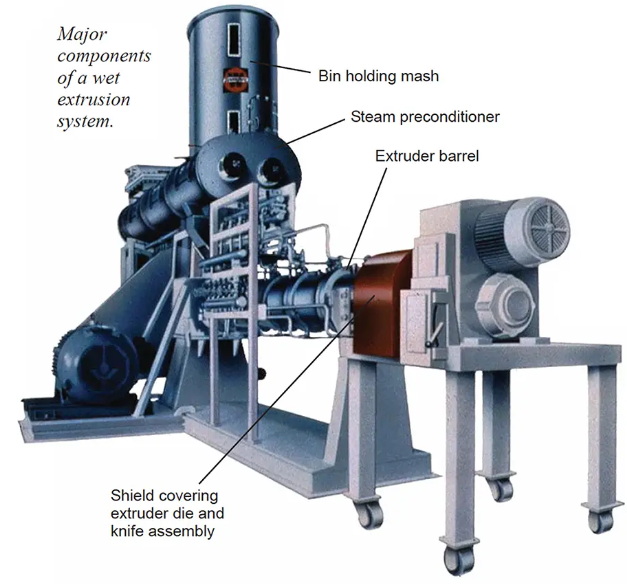

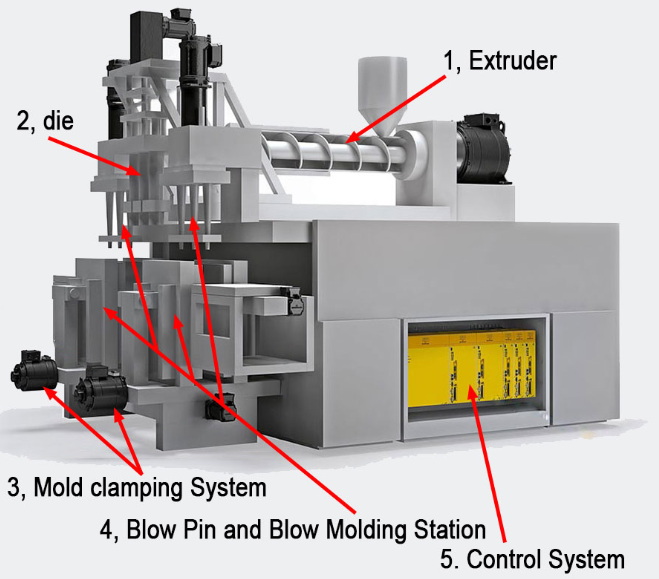

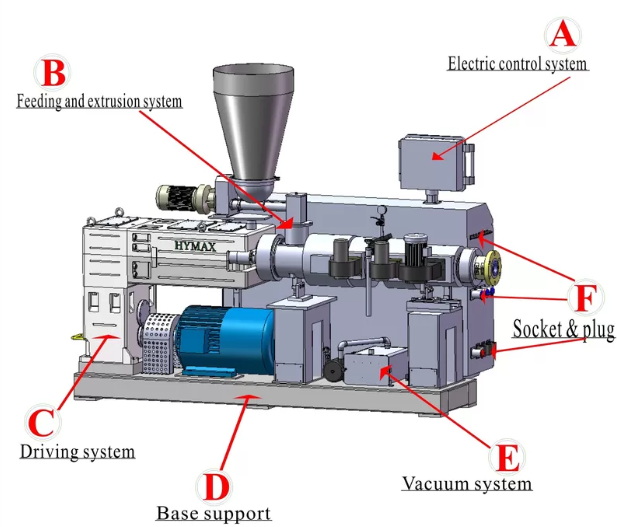

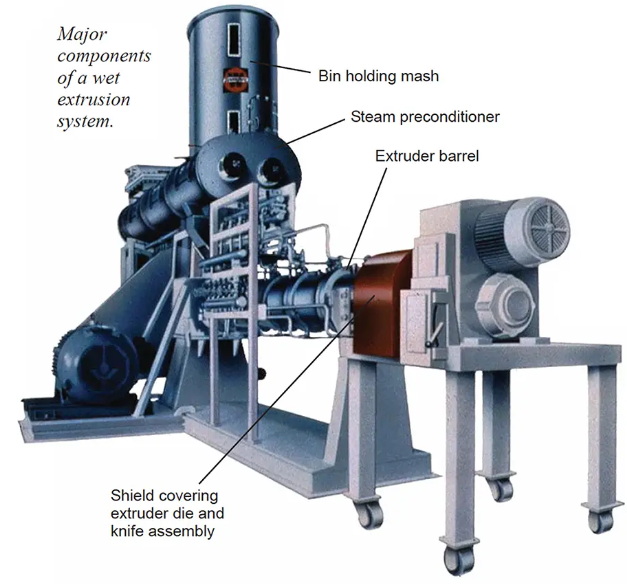

Key Components of Extrusion Machines

A typical extrusion machine consists of several integral components:

1. Hopper: Where raw material is loaded.

2. Barrel: Houses the extruder screw and is equipped with heaters.

3. Extruder Screw: Carries the material through the barrel, generating heat through friction.

4. Die: Shapes the molten material into the desired form.

5. Cooling System: Solidifies the extruded product.

Latest Trends in Extrusion Machinery

1. Technological Advancements

Manufacturers of extrusion machinery are integrating advanced technologies such as automation, AI, and IoT to optimize production efficiency and product quality. AI algorithms can analyze production data to predict potential defects and adjust extrusion conditions in real-time, enhancing overall efficiency and reducing waste.

2. Sustainability and Recycling

There is a growing emphasis on sustainable materials and practices in extrusion. Manufacturers of extrusion machinery are developing systems compatible with recycled and bio-based materials, supporting a circular economy and reducing environmental impact. The use of recycled plastics, for example, not only conserves natural resources but also reduces landfill waste and greenhouse gas emissions associated with producing new plastics.

3. Integration with 3D Printing

The integration of extrusion with 3D printing technologies offers new possibilities for complex geometries and customized products. This combination allows manufacturers to produce parts with intricate designs that cannot be achieved through traditional extrusion methods alone. For instance, in the aerospace industry, combining extrusion with 3D printing can create lightweight yet strong components with complex internal structures.

4. Industry 4.0 Technologies

The adoption of Industry 4.0 technologies, such as data analytics and digital twinning, enhances efficiency and predictive maintenance in extrusion processes. Digital twins allow for virtual testing and optimization of production lines before actual implementation, reducing downtime and improving overall performance. This approach also enables manufacturers to simulate different production scenarios, optimizing resource allocation and reducing energy consumption.

5. Energy Efficiency and Cost Reduction

Manufacturers of extrusion machinery are focusing on developing energy-efficient systems that reduce operational costs while maintaining high production standards. This includes optimizing extruder designs for better heat management and implementing advanced cooling systems that minimize energy consumption without compromising product quality.

Market Growth and Outlook

The global extrusion machinery market is expected to grow significantly, driven by technological innovations and rising demand for extruded products. The market size was valued at USD 8.93 billion in 2024 and is projected to grow at a CAGR of 4.5% from 2025 to 2030. This growth is fueled by increasing demand from emerging economies and the expanding use of extruded materials in various sectors.

Key Players and Innovations

Manufacturers of extrusion machinery such as Exlabesa, Rapidia, and Bausano & Figli S.p.A. are leading the way in innovation. For instance, Exlabesa expanded its extrusion capacity with a new high-capacity line in Portugal, enhancing energy efficiency and process optimization. These advancements not only improve production capabilities but also contribute to a more sustainable manufacturing environment.

Regional Market Analysis

The extrusion machinery market is diverse, with different regions contributing to its growth. Asia-Pacific is a major hub due to its large manufacturing base and growing demand for extruded products. Europe and North America also play significant roles, driven by technological advancements and stringent environmental regulations that encourage sustainable practices.

Impact of Global Events

Global events such as trade policies and economic fluctuations can impact the extrusion machinery market. However, the industry's resilience and adaptability have allowed it to navigate these challenges effectively. Manufacturers of extrusion machinery have been proactive in diversifying their supply chains and investing in technologies that enhance operational flexibility.

Future Developments

Looking ahead, the extrusion machinery market is poised for further innovation. Emerging trends include the integration of nanotechnology to enhance material properties and the development of more sophisticated AI-driven quality control systems. These advancements will not only improve product performance but also contribute to a more sustainable and efficient manufacturing process.

Conclusion

The extrusion machinery market is evolving rapidly, driven by technological advancements, sustainability, and automation. Manufacturers of extrusion machinery are at the forefront of this change, introducing innovative solutions that enhance efficiency, precision, and environmental responsibility. As the industry continues to grow, we can expect even more sophisticated and environmentally friendly extrusion processes.

FAQ

1. What role does AI play in extrusion technology?

AI contributes to extrusion technology by enabling real-time monitoring and adjustments. AI algorithms can analyze production data to optimize process parameters, improve product quality, and reduce waste.

2. How is sustainability impacting extrusion processes?

Sustainability plays a significant role in modern extrusion processes through the use of bioplastics, recycled materials, and energy-efficient designs. These practices help reduce environmental impact and align with global sustainability goals.

3. What are the benefits of integrating 3D printing with extrusion?

The integration of 3D printing with extrusion allows for the creation of complex geometries and customized products. This combination opens up new possibilities for manufacturing, enabling the production of parts that were previously difficult or impossible to extrude.

4. How do Industry 4.0 technologies enhance extrusion processes?

Industry 4.0 technologies, such as data analytics and digital twinning, enhance efficiency and predictive maintenance in extrusion processes. Digital twins allow for virtual testing and optimization of production lines before actual implementation, reducing downtime and improving overall performance.

5. What drives the growth of the extrusion machinery market?

The growth of the extrusion machinery market is driven by technological innovations, increasing automation, and rising demand for extruded products. The market will continue to evolve with advancements in AI, Industry 4.0 technologies, and sustainable practices.