Content Menu

● Introduction to PVC Extrusion

>> PVC Extrusion Process Overview

● Latest Innovations in PVC Extrusion Technology

>> Advancements in PVC Extrusion Equipment

>> Use of Biodegradable and Recycled Materials

>> Applications of PVC Extrusion

● Impact of PVC Extrusion Equipment on Industry

>> Role of PVC Extrusion in Sustainable Manufacturing

● Future of PVC Extrusion Technology

>> Emerging Trends in PVC Extrusion

>> Impact of Global Regulations on PVC Extrusion

>> Role of PVC Extrusion Equipment in Meeting Regulatory Requirements

● Technological Advancements in PVC Extrusion Machinery

>> Impact of Technological Advancements on PVC Extrusion Industry

● Conclusion

● FAQs

>> 1. What are the key innovations in PVC extrusion technology?

>> 2. How does PVC extrusion equipment contribute to sustainable manufacturing?

>> 3. What are the primary applications of PVC extrusion products?

>> 4. How does automation impact PVC extrusion processes?

>> 5. What role does twin-screw extruder technology play in PVC extrusion?

The PVC extrusion industry has witnessed significant advancements in recent years, driven by technological innovations and increasing demand for sustainable and efficient manufacturing processes. This article explores the latest developments in PVC extrusion technology, focusing on advancements in machinery, materials, and applications.

Introduction to PVC Extrusion

PVC extrusion is a process that involves melting PVC resin and shaping it into various profiles, such as pipes, sheets, and profiles used in construction and other industries. The process is highly versatile and can produce materials with diverse properties, making it a crucial component in modern manufacturing.

PVC Extrusion Process Overview

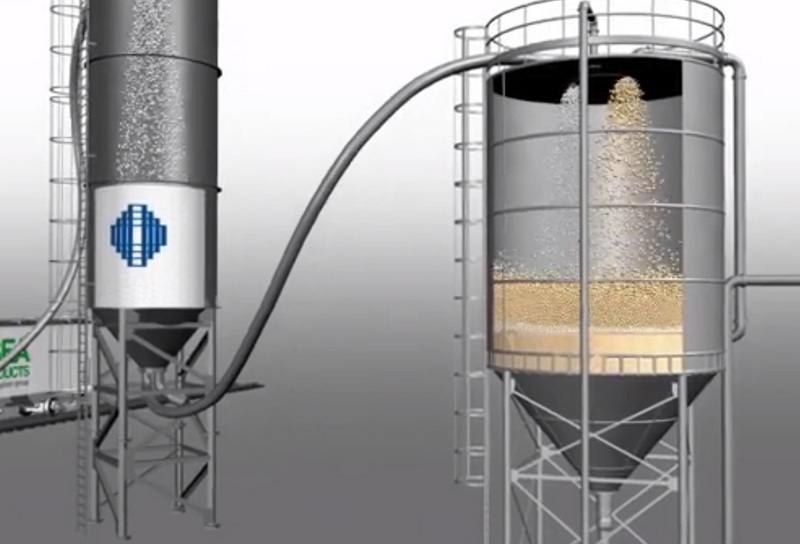

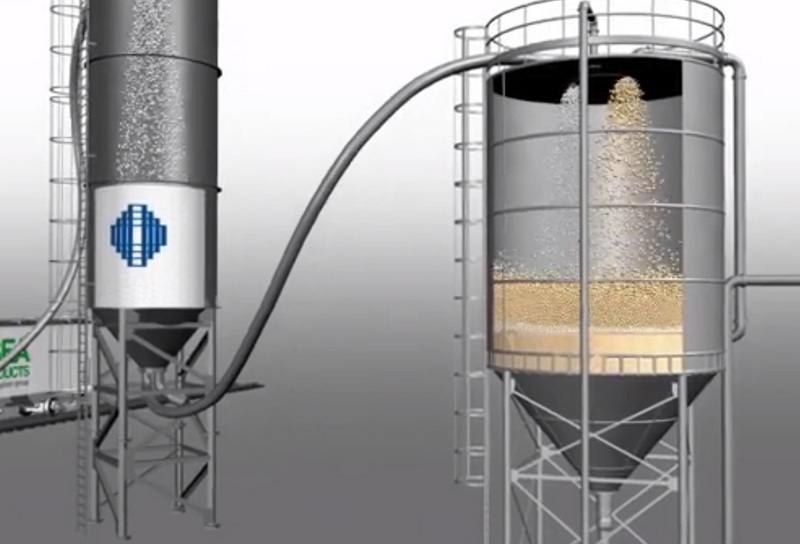

The PVC extrusion process typically begins with the preparation of PVC resin, which is mixed with additives to enhance its properties. The mixture is then fed into an extruder, where it is heated and melted. The molten PVC is forced through a die to form the desired shape, which is then cooled and cut to the required length.

Latest Innovations in PVC Extrusion Technology

Advancements in PVC Extrusion Equipment

Recent innovations in PVC extrusion equipment focus on improving efficiency, reducing energy consumption, and enhancing product quality. Key advancements include:

- Smart Extrusion Technologies: Integration of advanced analytics and IoT (Internet of Things) allows for real-time monitoring and predictive maintenance, optimizing production processes and reducing downtime.

- Energy Efficiency: Modern extruders are designed to be more energy-efficient, with optimized screw designs and advanced motor systems reducing energy consumption.

- Material Mixing Capabilities: Twin-screw extruders have improved mixing efficiency, enabling better control over material homogeneity and the production of complex polymer blends.

Use of Biodegradable and Recycled Materials

There is a growing trend towards using biodegradable and recycled materials in PVC extrusion. This shift is driven by environmental concerns and stricter regulations on plastic waste. European markets, in particular, have seen significant adoption of biodegradable polymers, with over 54% of new extrusion machine installations in 2024 designed to process these materials.

Applications of PVC Extrusion

PVC extrusion products are widely used across various industries:

- Construction Industry: PVC profiles are used in fenestration, fencing, and other building products due to their durability and cost-effectiveness.

- Packaging Sector: PVC sheets are used in packaging applications due to their lightweight and durable properties.

Impact of PVC Extrusion Equipment on Industry

The advancements in PVC extrusion equipment have significantly impacted the industry by improving production efficiency, reducing costs, and enhancing product quality. The integration of automation and smart technologies has allowed manufacturers to achieve higher precision and consistency in their products.

Role of PVC Extrusion in Sustainable Manufacturing

As industries strive for sustainability, PVC extrusion equipment is being designed to accommodate biodegradable materials and reduce waste. This shift towards eco-friendly practices is crucial for the long-term viability of the PVC extrusion industry.

Future of PVC Extrusion Technology

Looking ahead, the PVC extrusion sector is expected to continue its focus on sustainability and technological advancements. The integration of AI and machine learning will play a key role in optimizing production processes and improving product quality.

Emerging Trends in PVC Extrusion

Several emerging trends are shaping the future of PVC extrusion:

- Circular Economy Practices: There is an increasing emphasis on recycling and reusing PVC materials, reducing waste and promoting a circular economy.

- Advanced Material Formulations: Researchers are developing new PVC formulations with enhanced properties, such as improved UV resistance and thermal stability.

- Digitalization and Automation: The use of digital tools and automation is becoming more prevalent, enabling real-time monitoring and predictive maintenance of PVC extrusion equipment.

Impact of Global Regulations on PVC Extrusion

Global regulations, particularly those related to environmental sustainability and product safety, are influencing the PVC extrusion industry. Manufacturers must comply with these regulations by adopting eco-friendly practices and ensuring their products meet stringent safety standards.

Role of PVC Extrusion Equipment in Meeting Regulatory Requirements

PVC extrusion equipment is being designed to meet these regulatory demands by incorporating features that enhance sustainability and product safety. This includes the use of recycled materials, energy-efficient designs, and advanced quality control systems.

Technological Advancements in PVC Extrusion Machinery

Technological advancements in PVC extrusion machinery are driving innovation in the industry. Key developments include:

- High-Speed Extrusion: New extruders are capable of higher production speeds without compromising product quality, significantly increasing output and reducing production costs.

- Advanced Cooling Systems: Improved cooling systems allow for faster cooling times, enabling manufacturers to produce more complex profiles and reduce production cycles.

- Integration with Other Technologies: The integration of PVC extrusion with other manufacturing technologies, such as 3D printing, is opening up new possibilities for product design and customization.

Impact of Technological Advancements on PVC Extrusion Industry

These technological advancements are transforming the PVC extrusion industry by enhancing efficiency, reducing costs, and expanding product capabilities. As a result, manufacturers can produce a wider range of products with improved quality and consistency.

Conclusion

The PVC extrusion industry has undergone significant transformations in recent years, driven by technological innovations and environmental considerations. As the industry continues to evolve, it is likely that PVC extrusion equipment will play a crucial role in sustainable manufacturing practices and advanced material processing.

FAQs

1. What are the key innovations in PVC extrusion technology?

The latest innovations include smart extrusion technologies, improved material mixing capabilities, and the use of biodegradable materials. These advancements enhance efficiency, product quality, and sustainability.

2. How does PVC extrusion equipment contribute to sustainable manufacturing?

PVC extrusion equipment is being designed to process biodegradable materials and reduce waste, contributing to more sustainable manufacturing practices. This includes the use of recycled materials and energy-efficient machinery.

3. What are the primary applications of PVC extrusion products?

PVC extrusion products are widely used in the construction industry for fenestration and fencing, as well as in packaging for lightweight and durable sheets.

4. How does automation impact PVC extrusion processes?

Automation, through the integration of IoT and advanced analytics, allows for real-time monitoring and predictive maintenance. This enhances production efficiency, reduces downtime, and improves product consistency.

5. What role does twin-screw extruder technology play in PVC extrusion?

Twin-screw extruders offer better material mixing capabilities, higher throughput rates, and improved precision control. They are particularly useful for producing complex polymer blends and enhancing product quality.