Content Menu

● Understanding PV Battery Film Extrusion Technology

>> Key Components of PV Battery Film Extrusion

● Latest Innovations in PV Battery Film Extrusion

>> 1. Advanced Materials

>> 2. Enhanced Production Techniques

>> 3. Automation and Smart Manufacturing

● The Role of PV Battery Film Extrusion Production Lines

● Applications of PV Battery Films

● Future Trends in PV Battery Film Extrusion Technology

● Conclusion

● FAQ

>> 1. What materials are commonly used in PV battery film extrusion?

>> 2. How does automation impact the production of PV battery films?

>> 3. What is bifacial solar technology?

>> 4. What role do multi-layer extrusion technologies play?

>> 5. How does sustainability factor into future innovations?

● Citations:

The photovoltaic (PV) industry is experiencing rapid advancements, particularly in the domain of battery film extrusion technology. This evolution is crucial for enhancing the efficiency, durability, and overall performance of solar panels. As the demand for renewable energy sources continues to rise, innovations in PV battery film extrusion are becoming increasingly significant. This article explores the latest developments in this field, focusing on production lines, materials used, and the technologies that are transforming the landscape of solar energy.

Understanding PV Battery Film Extrusion Technology

PV battery film extrusion technology involves the process of creating thin films that serve as essential components in solar cells. These films are typically made from materials like Ethylene Vinyl Acetate (EVA) and Polyolefin Elastomer (POE), which provide encapsulation and protection for solar cells. The extrusion process itself is a method of shaping materials by forcing them through a die, creating films with specific properties tailored for solar applications.

Key Components of PV Battery Film Extrusion

- Extrusion Machines: These machines are critical for producing high-quality films. They come equipped with advanced features to ensure precision and consistency in film thickness and quality.

- Film Types: The most common types of films used in PV modules include EVA and POE films. EVA is widely used due to its excellent adhesive properties and cost-effectiveness, while POE offers superior weather resistance and durability.

- Production Lines: The production lines for these films have evolved significantly, incorporating automation and advanced control systems to enhance efficiency and reduce production costs.

Latest Innovations in PV Battery Film Extrusion

Recent innovations in PV battery film extrusion technology focus on improving material properties, enhancing production efficiency, and reducing environmental impact. Here are some notable advancements:

1. Advanced Materials

- Polyolefin Films: The shift towards polyolefin encapsulants like POE is gaining momentum due to their superior performance characteristics compared to traditional EVA films. POE films exhibit better resistance to moisture and UV radiation, which enhances the longevity of solar panels.

- Bifacial Solar Technology: Innovations in bifacial solar panels have led to increased demand for high-performance encapsulants that can withstand harsher environmental conditions while maximizing energy output from both sides of the panel.

2. Enhanced Production Techniques

- Continuous Extrusion Processes: Modern production lines are adopting continuous extrusion processes that allow for higher throughput while maintaining consistent film quality. This technique reduces waste and improves overall efficiency.

- Multi-layer Extrusion Technology: The implementation of multi-layer extrusion technology enables manufacturers to produce films with varying properties in a single pass. This flexibility allows for tailored solutions that meet specific application requirements.

3. Automation and Smart Manufacturing

- Industry 4.0 Integration: The integration of IoT devices and smart manufacturing practices into production lines has revolutionized the way PV battery films are produced. Real-time monitoring and data analytics help optimize processes, reduce downtime, and enhance product quality.

- Robotic Handling Systems: Automated robotic systems are being employed for material handling within production lines, improving safety and efficiency by minimizing human intervention during repetitive tasks.

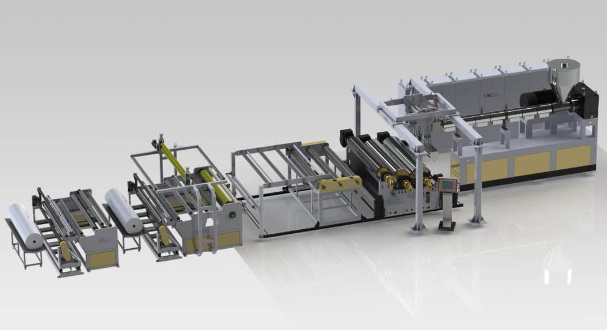

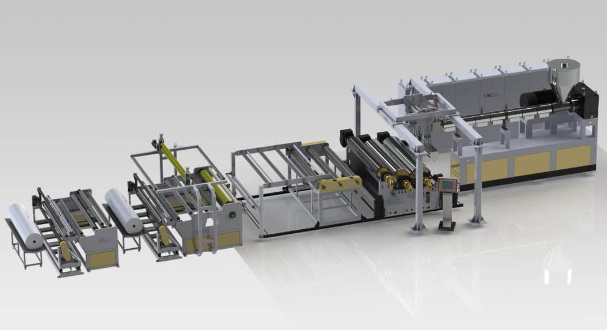

The Role of PV Battery Film Extrusion Production Lines

The design and operation of PV battery film extrusion production lines are critical to achieving high-quality outputs efficiently. These lines incorporate various stages that contribute to the final product's quality:

1. Material Preparation: Raw materials are prepared through processes such as drying and blending before being fed into the extruder.

2. Extrusion Process: The prepared materials are melted and forced through a die to form continuous sheets or rolls of film.

3. Cooling and Winding: After extrusion, the film is cooled using controlled methods before being wound onto rolls for storage or further processing.

4. Quality Control: Rigorous quality control measures are implemented throughout the production process to ensure that the final product meets industry standards.

Applications of PV Battery Films

PV battery films play a crucial role in various applications within the solar energy sector:

- Encapsulation of Solar Cells: Films like EVA and POE encapsulate solar cells, protecting them from environmental factors while ensuring optimal performance.

- Backsheet Protection: These films serve as backsheets that shield solar cells from moisture, UV rays, and mechanical damage.

- Flexible Solar Panels: Recent advancements have enabled the development of flexible solar panels that utilize lightweight films, making them suitable for diverse applications such as building-integrated photovoltaics (BIPV).

Future Trends in PV Battery Film Extrusion Technology

The future of PV battery film extrusion technology looks promising with several trends emerging:

- Sustainability Initiatives: There is an increasing focus on developing eco-friendly materials and processes that minimize environmental impact throughout the lifecycle of solar products.

- Research on New Materials: Ongoing research into alternative materials such as perovskites may lead to breakthroughs that further enhance efficiency and reduce costs in solar technology.

- Increased Demand for Energy Storage Solutions: As energy storage becomes more critical for managing renewable energy sources, innovations in battery separator films will also play a significant role in advancing battery technologies alongside PV systems.

Conclusion

The innovations in PV battery film extrusion technology represent a significant leap forward in enhancing the efficiency, durability, and overall performance of solar panels. By leveraging advanced materials, improved production techniques, and smart manufacturing practices, manufacturers can meet the growing demand for renewable energy solutions effectively. As this field continues to evolve, it will be essential to monitor emerging trends and technologies that can further drive sustainability and efficiency within the solar industry.

FAQ

1. What materials are commonly used in PV battery film extrusion?

Common materials include Ethylene Vinyl Acetate (EVA) and Polyolefin Elastomer (POE), which provide encapsulation and protection for solar cells.

2. How does automation impact the production of PV battery films?

Automation enhances production efficiency by reducing human intervention, minimizing errors, optimizing processes through real-time data analytics, and improving safety standards.

3. What is bifacial solar technology?

Bifacial solar technology involves using solar panels that can capture sunlight from both sides, increasing energy output compared to traditional single-sided panels.

4. What role do multi-layer extrusion technologies play?

Multi-layer extrusion technologies allow manufacturers to create films with varying properties in a single pass, providing tailored solutions for specific applications within the solar industry.

5. How does sustainability factor into future innovations?

Sustainability initiatives focus on developing eco-friendly materials and processes that minimize environmental impacts while enhancing efficiency throughout the lifecycle of solar products.

Citations:

[1] https://www.unimacts.com/blog-the-future-of-solar-module-how-innovations-in-module-technology-are-shaping-the-industry/

[2] https://www.plasticstoday.com/automotive-mobility/evs-drive-growth-in-battery-separator-film-extrusion-lines

[3] https://www.jwellextrusions.com/video/jwell-machinery-eva-solar-film-extrusion-line.html

[4] https://www.jwellextrusions.com/video/jwell-machinery-eva-poe-solar-film-extrusion-line.html

[5] https://www.jwellextrusions.com/the-production-method-of-poe-film-for-solar-photovoltaic-modules.html

[6] https://www.pv-magazine.com/2021/03/20/the-weekend-read-bifacial-drives-pv-encapsulant-switch/

[7] https://www.prnewswire.com/news-releases/prologium-technology-presented-its-film-free-next-generation-battery-technology-at-the-2024-solid-state-battery-summit-302255281.html

[8] https://www.jwellextrusions.com/what-is-poe-film-for-solar.html

[9] https://www.jjpvsolar.com/top-8-innovations-in-the-solar-industry

[10] https://www.jwellextrusions.com/video/sgp-solar-film-extrusion-line.html

[11] https://www.mdpi.com/2075-163X/14/7/638

[12] https://olympuspower.co.uk/latest-innovations-solar-power-technology/

[13] https://www.technologyreview.com/2024/10/01/1104255/2024-climate-tech-companies-first-solar-advanced-solar-panels/

[14] https://www.greenlancer.com/post/solar-panel-technology-trends

[15] https://manlybattery.com/are-perovskite-solar-cells-commercially-available/

[16] https://www.weforum.org/stories/2024/10/solar-panel-innovations/

[17] https://www.linkedin.com/pulse/bopp-film-extrusion-line-market-size-trends-report-5qrvc/

[18] https://www.perchenergy.com/blog/innovation/solar-panel-technology-advancements-perovskites-thin-film

[19] https://www.azocleantech.com/article.aspx?ArticleID=1593

[20] https://8msolar.com/advancements-in-solar-panel-technology/

[21] https://www.youtube.com/watch?v=xkuzV2oEthU

[22] https://www.youtube.com/watch?v=NqtRHtqbP38

[23] https://www.youtube.com/watch?v=JjPS2wrQyAc

[24] https://www.youtube.com/watch?v=iwPySRzht_4

[25] https://www.youtube.com/watch?v=U7P_QqNNxYM

[26] https://www.youtube.com/watch?v=yz-lQUcIKvY

[27] https://www.youtube.com/watch?v=vHTPmqyOrnE

[28] https://www.youtube.com/watch?v=DkV6yZSLBq8

[29] https://www.youtube.com/watch?v=AbGUjReWmeU

[30] https://www.powerfilmsolar.com/education/faqs

[31] https://pmc.ncbi.nlm.nih.gov/articles/PMC11207707/

[32] https://www.polystarco.com/blog-detail/frequently-asked-questions-about-blown-film-machines/

[33] https://eupegypt.com/blog/blown-film-extrusion/

[34] https://www.adaptationclearinghouse.org/resources/understanding-solar-storage-answers-to-commonly-asked-questions-about-solar-pv-and-battery-storage.html

[35] https://www.mdpi.com/2313-0105/9/11/555

[36] https://cloeren.com/applications/energy/

[37] https://www.laserax.com/blog/ev-battery-manufacturing-process

[38] https://www.jwellextrusions.com/video/jwell-machinery-eva-poe-solar-film-extrusion-machine-extrusion-line.html

[39] https://www.youtube.com/watch?v=eRBQAWIh8Sc

[40] https://www.plasticstoday.com/automotive-mobility/evs-drive-growth-in-battery-separator-film-extrusion-lines

[41] https://www.azom.com/article.aspx?ArticleID=21504