Content Menu

● Introduction to Copper Extrusion Machinery

>> Advantages of Copper Extrusion Machinery

● Latest Innovations in Copper Extrusion Machinery

>> 1. Continuous Rotary Extrusion (CRE) Technology

>>> Meltech's Strongform Technology

>> 2. Automation and Digitalization

>> 3. Energy Efficiency and Sustainability

>> 4. Material Compatibility and Advanced Alloys

● Trends and Future Prospects

>> 1. Increased Adoption of Radial Extrusion Machines

>> 2. Customization and Flexibility

>> 3. Sustainability and Environmental Impact

● Conclusion

● FAQs

>> 1. What are the primary applications of copper extrusion machinery?

>> 2. How does Continuous Rotary Extrusion (CRE) improve copper extrusion processes?

>> 3. What role does automation play in modern copper extrusion machinery?

>> 4. How are copper extrusion machines becoming more sustainable?

>> 5. What future trends can be expected in copper extrusion machinery?

● Citations:

The field of copper extrusion machinery has witnessed significant advancements in recent years, driven by the increasing demand for high-quality, efficient, and sustainable manufacturing processes. These innovations are crucial for meeting the needs of various industries, including automotive, aerospace, and electronics, where copper and its alloys play a vital role. This article will delve into the latest developments in copper extrusion machinery, highlighting key technologies, trends, and future prospects.

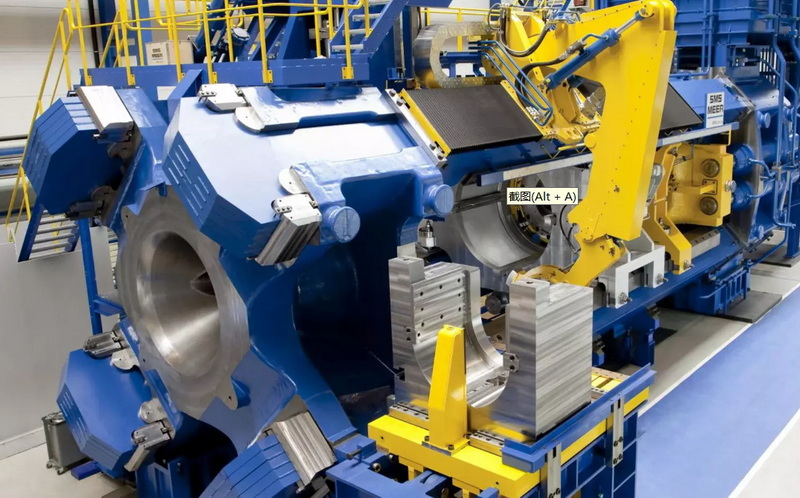

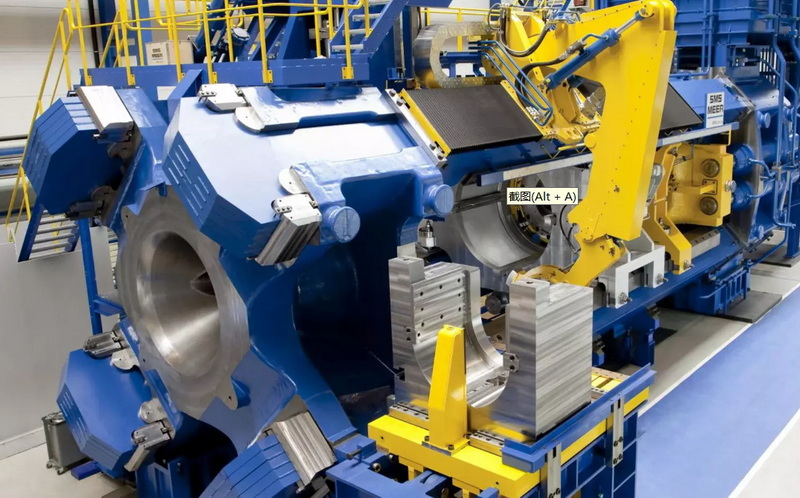

Introduction to Copper Extrusion Machinery

Copper extrusion machinery is designed to produce copper profiles through a continuous process, where copper billets are heated and then forced through dies to create the desired shapes. This process is essential for manufacturing components used in electrical wiring, heat exchangers, and other applications requiring high thermal and electrical conductivity.

Advantages of Copper Extrusion Machinery

1. High Efficiency: Copper extrusion machines can produce long, complex profiles with high precision and speed.

2. Material Versatility: These machines can process various copper alloys, offering flexibility in product design.

3. Environmental Benefits: Modern machinery often incorporates energy-saving technologies and reduced waste generation.

Latest Innovations in Copper Extrusion Machinery

1. Continuous Rotary Extrusion (CRE) Technology

Continuous Rotary Extrusion (CRE) is a game-changing technology in the field of copper extrusion. It offers improved productivity and product quality by utilizing a unique cantilevered extrusion wheel design. This setup allows for better control over the extrusion process, reducing waste and enhancing dimensional accuracy.

Meltech's Strongform Technology

Meltech, a leading innovator in CRE, has developed the Strongform series, which includes models like the Ex260, Ex300, Ex400, and Ex500. These machines are fully automated, providing high output rates for both copper and aluminum. For instance, the Ex500 model can produce up to 3,000 kg/hour of copper and 2,000 kg/hour of aluminum.

2. Automation and Digitalization

The integration of Industry 4.0 technologies, such as sensors, data analytics, and predictive maintenance systems, is transforming copper extrusion machinery. These advancements enhance operational efficiency, reduce downtime, and improve product quality.

3. Energy Efficiency and Sustainability

Modern copper extrusion machines are designed with energy efficiency in mind, incorporating technologies that reduce power consumption without compromising on product quality. This shift towards sustainability is crucial for meeting environmental regulations and reducing operational costs.

4. Material Compatibility and Advanced Alloys

There is a growing focus on developing machines capable of processing advanced materials like titanium and nickel-based superalloys. This expansion in material compatibility opens new avenues for copper extrusion machinery in aerospace and other high-tech industries.

Trends and Future Prospects

1. Increased Adoption of Radial Extrusion Machines

Radial extrusion machines are gaining popularity due to their higher production rates and ability to handle larger billets compared to curvilinear machines. This trend is driven by the increasing demand for high-strength aluminum alloys in various sectors.

2. Customization and Flexibility

Manufacturers are investing in flexible extrusion lines that can produce diverse geometries and complex cross-sections. This trend is driven by the growing demand for customized profiles in industries like aerospace and automotive.

3. Sustainability and Environmental Impact

The emphasis on sustainability is prompting the development of energy-efficient machines with reduced environmental impact. This includes innovations in waste management and emissions reduction.

Conclusion

The latest innovations in copper extrusion machinery are transforming the manufacturing landscape by offering higher efficiency, improved product quality, and enhanced sustainability. As industries continue to evolve, the demand for advanced copper extrusion technologies will remain strong, driving further innovation and growth in this sector.

FAQs

1. What are the primary applications of copper extrusion machinery?

Copper extrusion machinery is primarily used in industries such as automotive, aerospace, electronics, and construction for producing components like electrical wiring, heat exchangers, and structural profiles.

2. How does Continuous Rotary Extrusion (CRE) improve copper extrusion processes?

CRE technology enhances productivity and product quality by using a cantilevered extrusion wheel, allowing for better control over the extrusion process, reduced waste, and improved dimensional accuracy.

3. What role does automation play in modern copper extrusion machinery?

Automation, through technologies like sensors and predictive maintenance, enhances operational efficiency, reduces downtime, and improves product quality in copper extrusion machinery.

4. How are copper extrusion machines becoming more sustainable?

Modern copper extrusion machines are designed to be more energy-efficient, reducing power consumption while maintaining product quality. Additionally, there is a focus on minimizing waste and environmental impact.

5. What future trends can be expected in copper extrusion machinery?

Future trends include increased adoption of radial extrusion machines, customization and flexibility in production, and a continued focus on sustainability and environmental impact reduction.

Citations:

[1] https://www.promarketreports.com/reports/continuous-extrusion-machine-36294

[2] https://www.eplus3d.com/eplus3d-unveilsmeter-scalecopper-additive-manufacturing-with-red-laser-technology-at-tct-asia-2025.html

[3] https://www.themeltechcompany.co.uk/extrusion-technologies/

[4] https://www.youtube.com/watch?v=i1o4S1dghYI

[5] https://www.orientps.com/manufactur-standard-copper-extrusion-machine-continuous-extrusion-machinery-pengsheng-2-product/

[6] https://www.sms-group.com/insights/all-insights/new-developments-for-vertical-copper-casting-machines

[7] https://www.promarketreports.com/reports/continuous-rotary-extrusion-equipment-36290

[8] https://www.opsmachines.com/product/continuous-extrusion-machinery/

[9] https://www.copperexpo.com.cn/en-gb.html

[10] https://www.thebusinessresearchcompany.com/report/extrusion-machinery-global-market-report

[11] https://news.metal.com/newscontent/103235213/changrong-electronics-technology-invites-you-to-join-the-ccie-2025smm-20th-copper-industry-conference/

[12] http://southeast.newschannelnebraska.com/story/52530992/extruder-machinery-market-size-and-trends-2025

[13] https://www.konformgroup.com

[14] https://ilfproducts.co.uk/copper-extrusion/

[15] https://www.linkedin.com/pulse/continuous-extrusion-machine-market-opportunities-memnf/

[16] https://wohemachinery.en.made-in-china.com/product/VjgJzFBoMqcb/China-New-Technology-Copper-Extrusion-Machine-New-Aluminum-Extrusion-Press-New-Aluminum-Extrusion-Line.html

[17] https://swanwire.en.made-in-china.com/product/vQYRgmTuuKkP/China-2024-Best-Quality-14D-Fine-Copper-Wire-Drawing-Machine-with-online-annealing-machine-for-fine-copper-wire-drawing.html

[18] https://www.globalgrowthinsights.com/market-reports/indirect-extrusion-presses-market-107187

[19] https://continuousextrusion.com/3-alloy-copper-extrusion-equipment.html/114794/

[20] https://wiretech.com/2024/01/extrusion-machinery-tooling-roundup-2/

[21] https://www.konformgroup.com/product-continuous-rotary-extrusion-machine-for-copper-bus-bar.html

[22] https://www.youtube.com/watch?v=vcMnjjdq_Xo

[23] https://holtoncrest.com

[24] https://www.youtube.com/watch?v=hzc3yyRPrBU

[25] https://nbguangway.en.made-in-china.com/product-group/AbyGwfEuJzpM/Copper-Extrusion-catalog-1.html

[26] https://nbguangway.en.made-in-china.com/product/emVUMCNEJupn/China-Copper-Extrusions-with-Irregular-Sections-for-Innovative-Product-Designs.html

[27] https://www.youtube.com/watch?v=MX7xkUY3aK0

[28] https://www.shutterstock.com/search/copper-innovation?page=4

[29] https://www.youtube.com/watch?v=LuRgJoJF4BY

[30] https://www.copperexpo.com.cn/en-gb/about.html

[31] https://matalbaler.en.made-in-china.com/product/PmxrlzeymQYp/China-New-Copper-Extrusion-Machine-Achieves-Unprecedented-Precision-Levels-for-High-Quality-Copper-Profiles-.html

[32] https://www.youtube.com/watch?v=P8n-2X188DM

[33] https://www.rautomead.com/uploads/files/1515577710BWEconformprocess.pdf

[34] https://internationalcopper.org/wp-content/uploads/2021/08/ICA_TechRoadmap-201806-Web.pdf

[35] https://copper.org/publications/newsletters/innovations/1998/11/astm.html

[36] https://www.youtube.com/playlist?list=PLoqtn9Uh6SkXrtb6SUVZmMAsYAXbNjgDE